T200 User's Manual

PAGE VI

3.18 COMMUNICATIONS INTERFACE WIRING AND CONFIGURATION............................................3-82

3.19 T200 USER VISUAL INDICATIONS.....................................................................................................3-90

SECTION 4 MOTOR GUIDE.................................................................................................................................4-1

4.1 MOTOR SERVO-DRIVE SYSTEM........................................................................................................4-4

4.2 GLOBAL MOTOR MODELS AND ELECTRICAL TYPES .................................................................4-4

4.3 CONFIGURING THE MOTOR IN THE T200 SERVO-DRIVE ............................................................ 4-8

4.4 MOTOR-DRIVE SELECTION................................................................................................................4-10

4.5 MOTOR PERFORMANCE DATA..........................................................................................................4-11

4.6 MOUNTING AND INSTALLATION.....................................................................................................4-13

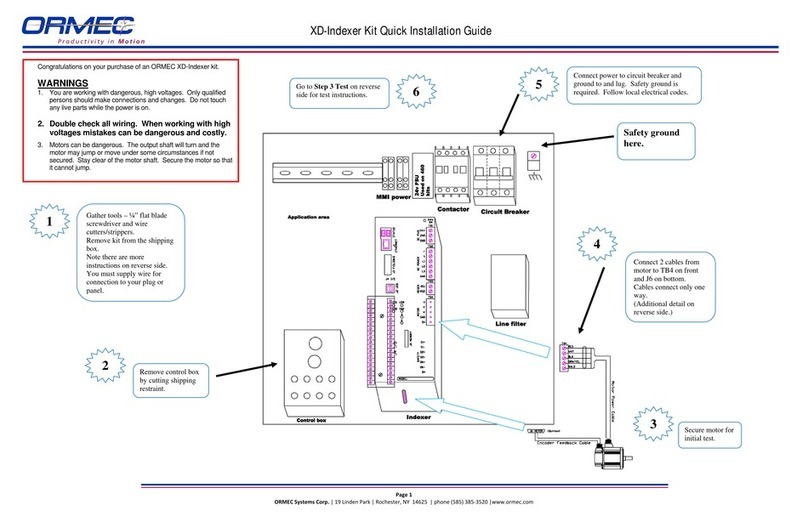

SECTION 5: QUICK-START ..................................................................................................................................5-1

5.1 GETTING STARTED .............................................................................................................................. 5-3

SECTION 6: T200 FUNCTIONAL OVERVIEW...................................................................................................6-1

6.1 INTRODUCTION ....................................................................................................................................6-5

6.2 T200 FUNCTIONALITY OVERVIEW...................................................................................................6-6

6.3 T200 CONVENTIONS............................................................................................................................. 6-11

6.4 POWER INTERFACE SECTION............................................................................................................6-12

6.5 INPUT AND OUTPUT FUNCTIONAL DESCRIPTION .......................................................................6-17

6.6 INTERNAL FUNCTION GENERATOR ................................................................................................ 6-25

6.7 CONTROL LOOP OVERVIEW..............................................................................................................6-28

6.8 FAULT DETECTION.............................................................................................................................. 6-51

6.9 SELF PROTECTION ............................................................................................................................... 6-61

6.10 ENCODER SIMULATION FUNCTION.................................................................................................6-64

6.11 INCREMENTAL ENCODER INPUT .....................................................................................................6-66

6.12 STEPPER MOTOR INTERFACE............................................................................................................6-68

6.13 COMMUNICATIONS INTERFACES ....................................................................................................6-70

6.14 PARAMETER STORAGE....................................................................................................................... 6-79

SECTION 7: WINDRIVE.........................................................................................................................................7-1

7.1 INTRODUCTION ....................................................................................................................................7-6

7.2 WINDRIVE SOFTWARE SET-UP .........................................................................................................7-6

7.3 STARTING WINDRIVE.......................................................................................................................... 7-7

7.4 RS232 AND RS485 COMMUNICATION .............................................................................................. 7-9

7.5 PASSWORD PROTECTION................................................................................................................... 7-13

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com