Moog MSD User manual

moog

MSD Servo Drive

User Manual

SERCOS III

moog MSD Servo Drive User Manual SERCOS III

User Manual – SERCOS III MSD Servo Drive

ID no.: CA97557-001, Rev. 1.0

Da te : 11/ 2 011

We reserve the right to make technical changes.

Technical alterations reserved.

The contents of our documentation have been compiled with greatest care and in com-

pliance with our present status of information.

Nevertheless we would like to point out that this document cannot always be updated

parallel to the technical further development of our products.

Information and specifications may be changed at any time. For information on the

latest version please refer to drives-support@moog.com.

moog MSD Servo Drive User Manual SERCOS III 3

How to use this document

Dear user,

This manual is intended for you as a project engineer, commissioning engineer or pro-

grammer of drive and automation solutions on the SERCOS III fieldbus.

It is assumed that you are already familiar with this fieldbus on the basis of appropriate

training and reading of the relevant literature. We assume your drive is already in opera-

tion. If it is not, you should put it into operation as described in the MSD Servo Drive

Operation Manual.

This manual applies to the MSD Servo Drive servo drive system with the SERCOS III op-

tion board.

11 Safety

44 Parameter setting

55 Data transfer

66 Scaling and weighting

77 Functionality

88 Error messages and diagnosis

99 Bibliography

1010 Appendix, Glossary

4

4

Parameter sett

i

n

g

33 Commissioning and configuration

3

3

Commissioning and configuration

22 Assembly and connection

moog MSD Servo Drive User Manual SERCOS III 4

Pictograms

To provide clear guidance, this Operation Manual uses pictograms. Their meanings are

set out in the following table. The pictograms always have the same meanings, even

where they are placed without text, such as next to a connection diagram.

!ATTENTION! Misoperation may result in damage to the drive or

malfunctions.

DANGER FROM ELECTRICAL TENSION! Improper behaviour may

endanger human life.

DANGER FROM ROTATING PARTS! Drive may start up automatically.

NOTE: Useful information

moog MSD Servo Drive User Manual SERCOS III 5

Table of contents

1 Safety ...................................................................................... 7

1.1 Measures for your safety.........................................................................................7

1.2 Read the Operation Manual first!............................................................................7

1.3 Introduction to the SERCOS III interface ..................................................................7

1.4 Key features ............................................................................................................8

1.5 Abbreviations..........................................................................................................9

2 Assembly and connection .......................................................11

2.1 Installation and wiring.............................................................................................11

2.2 Pin assignment of the RJ-45 socket.........................................................................11

2.3 Meanings of LEDs ...................................................................................................12

2.4 Indication of operating states on 7-segment display ...............................................12

2.5 Hardware enable ....................................................................................................13

3 Commissioning and configuration .......................................... 15

3.1 Commissioning .......................................................................................................15

3.2 Commissioning sequence........................................................................................15

3.3 Setting the slave bus address ..................................................................................16

4 Parameter setting................................................................... 17

4.1 Format of SERCOS III parameters.............................................................................17

4.1.1 Standard parameters (S-0-xxxx.x.x).............................................................17

4.1.2 Manufacturer-specific parameters P-0-xxxx ....................................................17

4.2 Operation modes ...................................................................................................17

4.3 Real-time bits..........................................................................................................19

5 Data transfer ......................................................................... 21

5.1 Communication phases...........................................................................................21

5.2 Cyclic data transfer..................................................................................................21

5.2.1 Mapping of configurable real-time data ......................................................21

5.2.2 Drive control word S-0-0134.0.0.......................................................................21

5.2.3 Description of bits 13-15..............................................................................22

5.2.4 Drive status word S-0-0135.0.0.........................................................................23

5.2.5 Non-configurable real-time data..................................................................24

5.3 Data transfer via the service channel (SVC) .............................................................24

5.4 IP channel ...............................................................................................................25

5.4.1 Parameter setting ........................................................................................25

5.4.2 SERCOS III IP address ...................................................................................25

6 Scaling and weighting ........................................................... 27

6.1 Weighting of position data .....................................................................................27

6.1.1 Weighting of translatory position data.........................................................27

6.1.2 Weighting of rotary position data................................................................27

6.1.3 Modulo weighting.......................................................................................29

6.1.4 Position polarity...........................................................................................29

6.2 Weighting of velocity data ......................................................................................30

6.2.1 Weighting of translatory velocity data .........................................................30

6.2.2 Weighting of rotary velocity data.................................................................30

6.2.3 Speed polarity .............................................................................................31

6.3 Weighting of acceleration data ...............................................................................32

6.3.1 Weighting of translatory acceleration data ..................................................32

6.3.2 Weighting of rotary acceleration data..........................................................32

6.4 Weighting of torque and force data........................................................................33

6.4.1 Percentage weighting of torque and force data ...........................................33

moog MSD Servo Drive User Manual SERCOS III 6

6.4.2 Weighting of force data...............................................................................33

6.4.3 Weighting of torque data ............................................................................34

6.4.4 Torque polarity ............................................................................................34

6.5 Scaling using the scaling wizard..............................................................................35

6.5.1 Scaling of position data ...............................................................................35

6.5.2 Scaling of velocity data ................................................................................36

6.5.3 Scaling of torque data .................................................................................36

6.5.4 Scaling of acceleration data .........................................................................37

7 Functionality .......................................................................... 39

7.1 Homing...................................................................................................................39

7.1.1 “Drive-controlled homing” command .........................................................39

7.1.2 Setting of SERCOS encoders 1 / 2 ................................................................39

7.1.3 Homing velocity...........................................................................................39

7.1.4 Homing acceleration....................................................................................39

7.1.5 Homing method ..........................................................................................39

7.1.6 Reference distance 1/2 ................................................................................39

7.1.7 Reference distance offset 1/2 ......................................................................39

7.1.8 Reference cam, limit switch .........................................................................39

7.1.9 Function selector - digital inputs and outputs..............................................40

7.2 Touchprobe function ..............................................................................................40

8 Error messages and diagnosis................................................. 45

8.1 Standard parameters for error diagnosis .................................................................45

8.1.1 Error messages in state class 1 (C1D) ...........................................................45

8.1.2 Warning messages in state class 2 (C2D) .....................................................45

8.1.3 Interface diagnosis.......................................................................................46

8.1.4 Telegram failure and error counter...............................................................46

8.2 Diagnosis using the internal oscilloscope.................................................................47

8.2.1 Standard parameters ...................................................................................47

8.2.2 Additional scope parameters .......................................................................48

8.3 Internal error list .....................................................................................................49

9 Bibliography........................................................................... 51

10 Appendix, Glossary................................................................ 53

10.1 Appendix A: Parameter list......................................................................................53

10.1.1 SERCOS III standard parameters...................................................................53

10.1.2 Manufacturer-specific parameters ...............................................................57

MSD Servo Drive User Manual SERCOS III 7

[ Chapter 1 ]

moog

1 Safety

1.1 Measures for your safety

The instructions set out below should be read through prior to initial commissioning in

order to prevent injury and/or damage to property. The safety instructions must be fol-

lowed at all times.

1.2 Read the Operation Manual first!

1.

Read the Operation Manual first!

• Follow the safety instructions!

• Refer to the user information!

Electric drives are dangerous:

• Electric voltages of 230 V to 480 V

Dangerously high voltages of ≥ 50 V may still be present 10 minutes after

the power is cut (capacitor charge). So check that the power has been cut!

• Rotating parts

• Hot surfaces

Protection against magnetic and/or electromagnetic fields during installation and

operation.

• Persons fitted with heart pacemakers, metallic implants and hearing aids etc.

must not be allowed access to the following areas:

– Areas where drive systems are installed, repaired and operated.

– Areas where motors are installed, repaired and operated. Motors with perma-

nent magnets pose a particular hazard.

Table 4.1 Safety instructions

DANGER: If it is necessary to access such areas, suitability to do so must be

determined beforehand by a doctor

Your qualification:

• In order to prevent personal injury or damage to property, only personnel with

electrical engineering qualifications may work on the device.

• The said qualified personnel must be familiar with the contents of the Operation

Manual (see IEC364, DIN VDE0100).

• Knowledge of national accident prevention regulations (e.g. BGV A3, formerly

VBG 4, in Germany)

U

V

N

L+

RB

L-

L3

L2

L1

U

V

N

L+

RB

L-

L3

L2

L1

During installation observe the following instructions:

• Always comply with the connection conditions and technical specifications.

• Comply with the standards for electrical installations, such as regarding cable

cross-section, PE conductor and ground connections.

• Do not touch electronic components and contacts (electrostatic discharge may

destroy components).

Table 4.1 Safety instructions

1.3 Introduction to the SERCOS III interface

SERCOS stands for SErial Realtime COmmunication System, and is a globally standard-

ized (IEC 61491 and EN61491) digital interface for communication between master con-

trol systems, drive units and other distributed peripherals. The real time-critical transfer

of setpoints and actual values enables numerically controlled high-performance drive

applications to be implemented in the engineering industry.

Services are also provided for operation mode recording, parameter setting, configura-

tion and diagnosis.

The SERCOS III communication module for the MSD Servo Drive is executed as an inter-

face with two RJ45 sockets, and so permits a loop or linear structure.

The hardware and software have, as far as possible, been developed in conformance to

DIN/EN 61491. The basis for SERCOS III implementation in the MSD Servo Drive is the

specification V1.1.1 from SERCOS International.

moog MSD Servo Drive User Manual SERCOS III 8

Further documentation

•MSD Servo Drive User Manual

•MSD Servo Drive Application Manual

•General Overview and architecture (V1.1.1.1) (SERCOS International)

•Generic Device profile (V1.1.0.6) (SERCOS International)

•SERCOS Communication (V1.1.1.5) (SERCOS International)

•Function specific profile drives (V1.1.2.11) (SERCOS International)

•SERCOS Parameter (V1.1.1.0) (SERCOS International)

ACHTUNG

WARNING

Kondensatorenent-

ladezeit > 3 min.

Betriebsanleitung

beachten!

Capacitor discharge

time > 3 min.

Pay attention to the

operationmanual!

X

36

X

37

H

1

Figure 4.1 SERCOS III communication module for MSD Servo Drive

The power supply to the communication module is provided by the MSD Servo Drive.

Real-time capability permits highly dynamic drive engineering applications with NC cycle

times of 125µs to 65 ms (multiples of 125µs). The data to be transferred is defined in

the SERCOS driver in numerous preference telegrams and parameters. They are specially

tailored to the high demands of electric drive systems. A freely configurable telegram

permits optimum utilization of all the possibilities offered by the line based on additional

setpoint and actual value parameters such as increasing the transferred position resolu-

tion, use of the inputs and outputs in the drive in the NC cycle, and much more.

1.4 Key features

•Cyclic data exchange of references and actual values with exact time equidistance

•SERCOS cycle time of 125µs to 65 ms (multiples of 125µs programmable)

•Multi-axis synchronization between reference action times and actual value meas-

urement times of all drives in the loop

•Full synchronization of all connected drives with the master control system

•Free configuration of telegram content

•Maximum configurable data volume in MDT: 20 bytes

•Maximum configurable data volume in DT: 20 bytes

•Programmable parameter weighting and polarity for position, velocity, acceleration

and torque

•Additive velocity and torque references

•Fine-interpolation (linear or cubic) inside the drive

•Optionally master control-side (external) or in-drive generation of rotation speed

and acceleration pre-control

•Service channel for parameter setting and diagnosis

•Support for touch probes 1 and 2

•Support for spindle commands

•Support for configurable real-time status and control bits

•Support for configurable signal status and control word

MSD Servo Drive User Manual SERCOS III 9

[ Chapter 1 ]

moog

1.5 Abbreviations

Abbreviation Explanation

DT Drive Telegram. Data from drive to master (status, actual values)

IDN Ident number S-x-yyyy or P-x-yyyy

32 bits are available to display a SERCOS III ident number.

MDT Master Data Telegram. Data from the master to the drives (control word,

setpoints)

MST Master Sync Telegram. Provides µs-precise data synchronization of the drives

by the time-slot method

SERCOS Standardized method of real-time communication between master control

systems and drives to DIN/EN 61491

SVC service channel Subsidiary protocol in the telegrams

Parameter values, attributes, scaling and names can be sequentially trans-

ferred.

Transfers can also be effected in parallel with the time-critical cyclic data

(MDT, DT) in phases 3 and 4.

The service channel provides services for operation mode recording, param-

eter setting, configuration and diagnosis

Cyclic data Time-synchronized transfer of MDT, DT as from phase 3, valid as from phase 4

Table 4.2 Abbreviations

moog MSD Servo Drive User Manual SERCOS III 10

moog MSD Servo Drive User Manual SERCOS III 11

[ Chapter 2 ]

2 Assembly and connection

2.1 Installation and wiring

In contrast to the SERCOS II (which used a fibre-optic cable), the connection between

the master and slave with SERCOS III is made using standard Ethernet cables with RJ45

connectors. The SERCOS III option board features two RJ45 sockets (X36, X37), enabling

a loop or linear structure.

Ethernet patch cables or crossover cables to the CAT5e-specification are suitable as con-

necting cables.

Figure 2.1

Line

Master

P1 P2

MSD

Servo Drive

P1 P2

MSD

Servo Drive

P1 P2

MSD

Servo Drive

P1 P2

SERCOS III linear structure

Figure 2.2

Master

P1 P2 Loop

MSD

Servo Drive

P1 P2

MSD

Servo Drive

P1 P2

MSD

Servo Drive

P2 P1

SERCOS III loop structure

The loop structure should be selected whenever possible, as in it the master sends the

telegrams in both direction, so enabling redundant communication. This means breaks

in the loop between two slaves, or between the master and a slave, are detected and

within a bus cycle the switch is made to a linear structure with two lines, so communica-

tion is not interrupted.

This redundancy is not possible with a linear structure.

The individual ports between the bus stations can be connected in any way, meaning

there is no specification of which port is the input and which the output.

2.2 Pin assignment of the RJ-45 socket

The pins on the RJ-45 socket are assigned as follows:

Pin Colour Cable wire pair Function

1White/orange 2TxData +

2Orange 2TxData -

3White/green 3 RecvData +

4Blue 1Unused

5White/blue 1Unused

6Green 3 RecvData -

7White/brown 4Unused

8Brown 4Unused

Table 2.1 Pin assignment

Figure 2.3

1234 5678

24

1

3

Pair #

RJ-45 socket

moog MSD Servo Drive User Manual SERCOS III 12

2.3 Meanings of LEDs

There are two LEDs on each RJ-45 socket. They signify the following.

LED Meaning

1 (green) Link LED:

• Off: No link No connection to another station

• On: Link active Connection to another (bus) station active

2 (orange) Activity:

• Off: No activity No data transfer is taking place

• Flashing: Activity Data transfer active

Table 2.2 Meanings of LEDs

2.4 Indication of operating states on 7-segment

display

D1 D2 Meaning Parameter

System states

8.

8.

Device in reset state

0.

Self-initialization on device startup (Start)

S.*) 1.

1) Not ready (no DC-link voltage) (NotReadyToSwitchOn)

S.*) 2.

1) Switch-on disabled (DC-link OK, power stage not

ready) (SwitchOnDisabled)

3.

Ready (power stage ready) (ReadyToSwitchOn)

4.

On (device powered up)2) (SwitchedOn)

5.

Drive ready (power applied to drive and drive ready

for setpoint input) 2) (OperationEnable)

6.

Quick stoP-0-2) (QuickStopActive)

7.

Error response active 2) (FaultReactionActive)

D1 D2 Meaning Parameter

E R

Errors (see below) (Fault)

In event of an error, alternating display

ER.

Display for errors, or non-resettable errors

X Y

Error number (decimal)

X Y

Error localization (decimal)

1) S. flashes when the STO (Safe Torque Off) function is active; no display when function is inactive.

*) Not a "safe indication" as specified in EN 61800-5-2.

2) The dot flashes when the power stage is active.

Example of flash sequence:

ER > 02 > 05 * ER > 02 > 05 ...

Error: ER = Error

Error name: 02 = Error in parameter list

Description of error: 05 = Function to check current parameter list

moog MSD Servo Drive User Manual SERCOS III 13

[ Chapter 2 ]

2.5 Hardware enable

The MSD Servo Drive has a control input to the hardware enable ENPO on the control

terminal. This input must be configured for operation of the power stage at 24 V.

The device additionally features the STO (Safe Torque Off) function (see MSD Servo Drive

User Manual or Application Manual), category 3, control terminal ISDSH. On these de-

vices the logic for this function must be provided by the higher-order drive as detailed in

the Application Manual.

Note: If the ENPO and ISDSH inputs are not configured, the device remains

in state 1 = “Not Ready to Switch On” or 2 = “Switch On Disabled”). Only

when the configuration has been correctly wired can the state be quit by way

of a “Shutdown” command over bus.

moog MSD Servo Drive User Manual SERCOS III 14

moog MSD Servo Drive User Manual SERCOS III 15

[ Chapter 3 ]

3 Commissioning and

configuration

3.1 Commissioning

The Moog

DriveADministr Ator

user interface is a program for general commissioning of

the drive system. The Moog

DriveADministr Ator

package includes tools for identification

of motor data, for servo motor access to a motor database, and for general device

configuration.

A separate section is devoted to initial commissioning via the user interface as described

in the device Application Manual.

3.2 Commissioning sequence

Preconditions:

•The drive unit is wired as specified in the Operation Manual and initial

commissioning is complete.

•If the motor is to be powered, the hardware enable (ENPO) and STO (Safe Torque

Off) must also be correctly configured.

NOTE: For more detailed information on optimization of the software

functions and control circuits refer to the device application manual.

Step Action Comment

1.

Check the wiring. Make sure hardware en-

able ENPO (X4) is not connected.

2.

Switch on the mains supply voltage.

3.

Configure the drive unit using the Applica-

tion Manual.

(Inputs/outputs, software

functions, ...)

4.

Test the control quality and optimize

the drive settings as necessary using the

Operation Manual.

5.

Set the communication parameters for the

SERCOS III.

6.

Test the drive on the higher-order drive,

see Application Manual.

7.

Finally save the setting. Save device setting

Non volatile in device

NOTE: On the subject of “Units and scalings" refer to Section 6

moog MSD Servo Drive User Manual SERCOS III 16

3.3 Setting the slave bus address

SERCOS parameter IDN/S-0-1040.0.0 is used to set the bus address. This parameter

can be written using Moog

DriveADministr Ator

5. The address setting must be unique,

meaning each address may be used only once in a SERCOS loop.

SERCOS III also supports automatic slave addressing. If you enter the address 0 for all

the slaves in a loop in IDN/S-1040-0-0, the addressing is executed automatically by the

master on bus startup, provided the master supports that mode of addressing.

moog MSD Servo Drive User Manual SERCOS III 17

[ Chapter 4 ]

4 Parameter setting

4.1 Format of SERCOS III parameters

The SERCOS III parameter numbers have been extended from SERCOS II, to a length of

32 bits. A standard parameter now has the following format:

S-<DataSet>-<IdNr>.<SI>.<SE>

Key to abbreviations:

•S: Standard parameter

•DataSet: Number of the data set (currently only data set 0 is supported)

•IdNr: SERCOS ident number

•SI: Structure instance

•SE: Structure element

In a connection between master and slave there is always a "producer" and at least one

"consumer". The "producer" connection is the one from the master to the slave, and the

"consumer" from the slave to the master. The connections are represented within the

parameter numbers by "SI" (structure instance).

Which instance is configured as the producer and which as the consumer is indicated by

parameter S-0-1050.x.1 (to be found under device parameter 21050) in

Moog

DriveADministr Ator

5. Bit 14 of that parameter defines the connection method. If,

for example, in parameter S-0-1050.0.1 bit 14 = 0, structure instance 0 is the consumer

instance. So bit 14 in parameter S- 0-1050.1.1 must be = 1, meaning structure instance 1

would be the producer instance. So according to this example the parameter structure

S-0-1050.0.20 is a consumer instance.

Multiple consumers per connection are permitted. The MSD Servo Drive supports a

connection with one producer and a maximum of one consumer.

4.1.1 Standard parameters (S-0-xxxx.x.x)

All standard parameters supported by the MSD Servo Drive are mapped as Moog

parameters. However, the expansion in SERCOS III parameter numbers mentioned

previously means that consecutive addressing of the Moog parameters could not be

retained. Only the parameters already existing previously in the parameter set as SERCOS

II parameters retain their addressing:

SERCOS Idn = Moog ID – 10000

All SERCOS III-specific parameters as from Moog parameter number 11000 and 20000

are stored in the parameter set of the MSD Servo Drive.

4.1. 2 Manufacturer-specific parameters P-0-xxxx

All manufacturer-specific parameters are to be found in list S-0-1017.0.0 with an offset of

8000(hex) from the Moog parameter number.

So Moog parameter 107 (function selector ISD06), for example, is to be found in the

list of all available parameters (S-0-1017.0.0) under number 32875. This parameter is

addressed by way of its Moog parameter number – in this case P-0-0107.

4.2 Operation modes

The operation modes selectable in the master control word and displayed in the drive

status word conforming to the SERCOS specification are coded according to the scheme

set out in the following table.

Bit Explanation

15 0: SERCOS default mode

1: Manufacturer-specific mode

14 - 10 Reserved

9 0: Without axis control word (S-0-0520.0.0)1:

1: With axis control word (S-0-0520.0.0) (not supported)

80: Without transition

1: With transition

Table 4.1 Operation mode coding

moog MSD Servo Drive User Manual SERCOS III 18

Bit Explanation

7 - 4 Advanced mode

0000: No advanced mode

0001: Interpolation

0010: Positioning

0011: Block mode (not supported)0100:

0100: Synchronous mode (not supported)

3 0: with tracking error

1: without tracking error

2 - 0 Operation mode

Table 4.1 Operation mode coding

The operation modes supported by the MSD Servo Drive are listed in parameter

S-0-0292.

Operation mode Description

0000 0000 0000 0001 Torque control

0000 0000 0000 0010 Speed control, drive-controlled profile generation with parameterized ramps

0000 0000 0100 0010 Speed control, master control system-controlled profile generation, no tracking error

0000 0000 0000 0011 Position control with position encoder 1 (e.g. motor encoder), master control sys-

tem- controlled profile generation, no use of pre-control signals, with tracking error

0000 0000 0000 0100 Position control with servo drive 2 (e.g. external encoder), master control system-

controlled profile generation, no use of pre-control signals, with tracking error

0000 0000 0000 1011 Position control with servo drive 1 (e.g. motor drive), master control system-

controlled profile generation, with use of pre-control signals, without track-

ing error

0000 0000 0000 1100 Position control with servo drive 2 (e.g. external encoder), master control

system-controlled profile generation, with use of pre-control signals, without

tracking error

0000 0000 0001 0011 Position control with servo drive 1 (e.g. motor encoder), drive-controlled

profile generation, no use of pre-control signals, with tracking error

0000 0000 0001 0100 Position control with servo drive 2 (e.g. external encoder), drive-controlled

profile generation, no use of pre-control signals, with tracking error

0000 0000 0001 1011 Position control with servo drive 1 (e.g. motor encoder), drive-controlled

profile generation, with use of pre-control signals, without tracking error

0000 0000 0001 1100 Position control with servo drive 2 (e.g. external encoder), drive-controlled

profile generation, with use of pre-control signals, without tracking error

Table 4.2 Supported operation modes

Using parameters S-0-0032.0.0 to S-0-0035.0.0, up to four different operation modes

can be configured. The mode is selected by parameter S-0-0134.0.0 "Drive control

word" (see section 5.2.1.1). This defines the configured mode in which the drive is to

run.

Which of the three possible encoder interfaces of the MSD Servo Drive (Channel 1,

Channel 2, Channel 3) are designated as position encoder 1 and 2 respectively is

specified by parameters P-0-0530 “Selection of position encoder 1”, and P-0-0531

“Selection of position encoder 2”.

The position encoder for position control specified by the operation mode must also be

selected via parameter P-0-0522 as the position encoder for position control. Otherwise

an error will be triggered in response to the drive enable and the switch from phase 2 to

phase 3.

For further details on encoder configuration please refer to the MSD Servo Drive

Operation Manual.

A valid interpolation method (P-0-0370) must be configured for the position-controlled

operation mode. The following settings are possible:

1. Linear interpolation

Calculation of position and rotation speed

Spline interpolation with external pre-control.

Should only be used when the master control system also calculates and transmits

the pre-control signals for speed (P-0-3055) and torque (P-0-3056).

2. Spline Interpolation

Calculation of position, rotation speed and torque

3. Spline Interpolation

Calculation of position, rotation speed and torque

To attain a higher resolution of the pre-control signals, an additional 16-bit decimal

place component (P-0-3100) for the position (S-0-0047) can be transferred.

To use the higher resolution, the advanced pre-control mode (P-0-0379=1) must be

selected.

The advanced pre-control mode (P-0-0379) can deliver an improvement in pre-control

signals even without calculating P-0-3100, though this depends heavily on the scaling

(position resolution) and must be checked on the line in each individual case.

For more information on scaling and interpolation please refer to the MSD Servo Drive

Operation Manual.

moog MSD Servo Drive User Manual SERCOS III 19

[ Chapter 4 ]

4.3 Real-time bits

There are two configurable real-time bits in the MDT and the DT respectively. They

are located in the "connection control word“ (bit numbers 6 + 7) and so in the non-

configurable part of the real-time data. These real-time bits are configured using

parameters:

•S-0-1050.x.20 "IDN assignment to real-time bit": IDN of the parameter to be

assigned to the real-time bit concerned.

•S-0-1050.x.21 "Bit assignment to real-time bit": Definition of which bit number of

the assigned parameter is to be mapped.

Only the parameters listed in P-0-3003 “Real-time control bits” or P-0-3002 “Real-time

status bits” can be assigned. Lists P-0-3002 and P-0-3003 are described in the following

tables.

Parameter Description

S-0-0405 Enable touchprobe 1

S-0-0406 Enable touchprobe 2

P-0-0141 Open-loop control of digital outputs via COM option

Table 4.3 Configurable real-time control bits (P-0-3003)

P-0-3002: Configurable real-time status bits

Parameter Description

S-0-0011 State class 1 (C1D)

S-0-0012 State class 2 (C2D)

S-0-0014 Interface status

S-0-0144 Signal status word

S-0-0179 Touchprobes 1 + 2 status

S-0-0310 Warning threshold I2t motor exceeded

S-0-0311 Warning threshold heat sink temperature exceeded

S-0-0312 Warning threshold motor temperature exceeded

S-0-0330 Status speed setpoint reached

Table 4.4 Configurable real-time status bits (P-0-3002)

Parameter Description

S-0-0331 Standstill message

S-0-0332 Speed threshold undershot

S-0-0333 Speed threshold exceeded

S-0-0334 Torque limit reached or exceeded

S-0-0335 Speed limit reached or exceeded

S-0-0336 Target position reached

S-0-0341 Status in track position

S-0-0401 Status touchprobe 1

S-0-0402 Status touchprobe 2

S-0-0403 Status actual position

S-0-0409 Touchprobe 1 positive edge recorded

S-0-0410 Touchprobe 1, negative edge recorded

S-0-0411 Touchprobe 2, positive edge recorded

S-0-0412 Touchprobe 2, negative edge recorded

S-0-0419 Status of setpoint transfer

P-0-0121 Status of the digital inputs

P-0-0143 Status of the digital outputs

P-0-0239 Functional status of the digital inputs

Table 4.4 Configurable real-time status bits (P-0-3002)

moog MSD Servo Drive User Manual SERCOS III 20

Other manuals for MSD

3

Table of contents

Other Moog Servo Drive manuals

Moog

Moog Class 5 SmartMotor User manual

Moog

Moog G400 Series User manual

Moog

Moog DS2020 Mounting instructions

Moog

Moog MSD User manual

Moog

Moog SmartMotor Instruction Manual

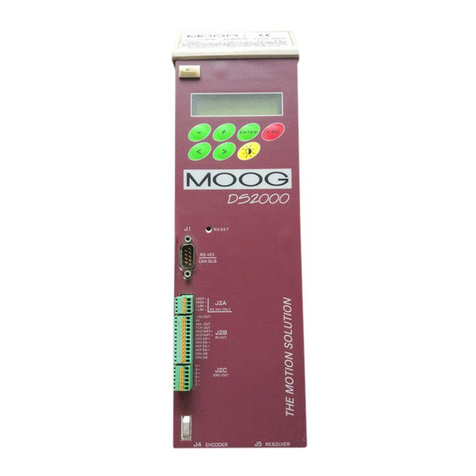

Moog

Moog DS2000 User manual

Moog

Moog MSD User manual

Moog

Moog DS2020 Installation manual

Moog

Moog T200 User manual

Moog

Moog G392-004 User manual