MSD Single-Axis System Operation Manual AC-AC Servo Drive

ID no.: CA65642-001 06/2018

moog 7

General

1 General

The product CD from Moog contains the complete documentation for the related

product series. The documentation for a product series includes the Operation Manual

(hardware description), device help (software description) as well as further user manuals

(e.g. eld bus description) and specications. The documents are available in the format

PDF, HTML or chm.

1.1 Target group

Dear user,

the documentation forms part of the device and contains important information on

operation and service. It is aimed at all persons who undertake mounting, installation,

commissioning and servicing work on the product.

1.2 Prerequisites

Prerequisites for the usage of devices from Moog:

yThe documentation on the devices is to be stored so it legible, accessible at all times and for the

entire life of the product.

yRead and ensure you understand the documentation on your device.

yQualication: to prevent injury or damage, personnel may only work on the device if they have

electrical engineering qualications.

yKnowledge required:

− National health and safety regulations (e.g. DGUV V3 in Germany)

− Mounting, installation, commissioning and operation of the device

Work in other areas, for example transport, storage and disposal is only allowed to be

undertaken by trained personnel.

NOTE

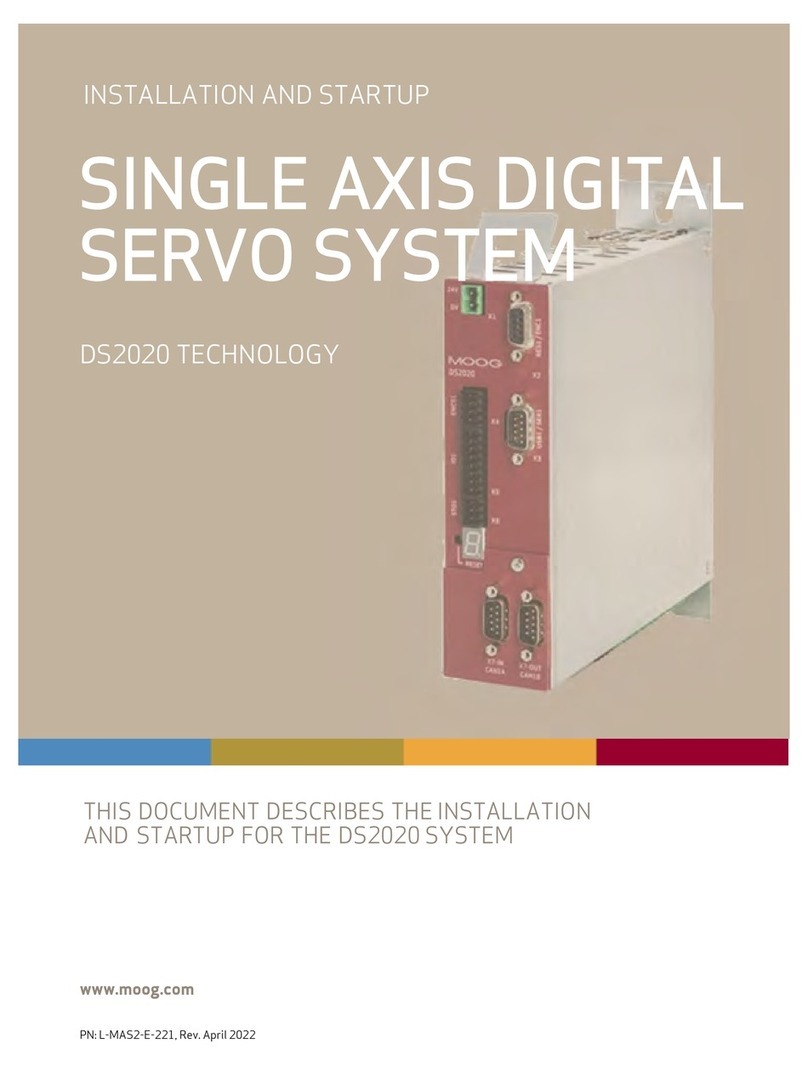

This operation manual applies to the AC-AC servo drive of the

MSD Single-Axis System (referred to in the following as the servo drive or

MSD Servo Drive for short).

1.3 Reference documents

Document Contents ID no.

Format

MSD Single-Axis

Servo Drive Compact-

Operation Manual

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specications, certication and

applicable standards, technical data

CA97555-001

PDF

MSD Servo Drive

AC-AC Servo Drive

Single-Axis System -

Operation Manual

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specications, certication and

applicable standards, technical data

CA65642-001

PDF

MSD Servo Drive

DC-AC Servo Drive

Multi-Axis System-

Operation Manual

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, STO, operation with AC-AC Servo Drive as supply,

planning, application example, specications, certication and

applicable standards, technical data

CA97554-001

PDF

MSD Power Supply Unit

Multi-Axis System-

Operation Manual

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, specication, certication and applicable standards,

technical data

CA97556-001

PDF

MSD Servo Drive

Sercos II -

User Manual

Safety, commissioning, communication phases, parameter interface,

error, warning and status messages, operation modes, weighting,

referencing, touchprobe, parameter lists

CA65648-001

MSD Servo Drive

Sercos III -

User Manual

Safety, installation and connection, commissioning and conguration,

setting parameters, data transmission, scaling and weighting,

functionality, error message and diagnostics, parameter lists

CA97557-001

PDF

MSD Servo Drive

Field bus systems

CANopen/EtherCAT -

User Manual

Safety, commissioning, data transmission, operation modes,

referencing, parameters, technical data

CA65647-001

PDF

MSD Servo Drive

Field bus systems

Probus/Pronet -

User Manual

Description and conguration of the parameters for the MSD Servo

Drive on the PROFIBUS/PROFINET eld bus system CA65645-001

Modular Multi-Axis

Servo Drive System -

MSD - Ordering Catalog

Information, notes on ordering, specications and technical data

on:

MSD Single-Axis Servo Drive Compact, MSD Single-Axis System,

MSD Multi-Axis System, safety technology, communication,

technology, function packages, accessories and motors

CDL 29950-en

MSD Servo Drive -

Device Help

Description of the software functionality MSD Servo Drive, rmware

versions:

- MSD Single-Axis Servo Drive Compact from V1.30-xx

- MSD Single-Axis System from V3.25-xx

- MSD Multi-Axis System from V3.25-xx

CB40859-001

PDF and HTML

Program help

Moog DriveADminsitrAtor 5

PC user software

Context-sensitive help for Moog DriveADministrAtor version 5.x

graphic PC user software for initial commissioning and serial

commissioning, operation, diagnostics and project management

CB19692-001