INTRODUCTION

NIOSH APPROVAL INFORMATION

CAUTIONS AND LIMITATIONS

I- Contains electrical parts which have not been evaluat-

ed as an ignition source in flammable or explosive

atmospheres by MSHA/NIOSH.

J- Failure to properly use and maintain this product could

result in injury or death.

M- All approved respirators shall be selected, fitted, used

and maintained in accordance with MSHA, OSHA and

other applicable regulations.

N- Never substitute, modify, add or omit parts. Use only

exact replacement parts in the configuration as speci-

fied by the manufacturer.

O- Refer to Users Instructions, and/or maintenance man-

uals for information on use and maintenance of these

respirators.

S- Special or critical User’s Instructions and/or specific

use limitations apply. Refer to user instructions before

donning.

CAUTIONS AND LIMITATIONS OF USE FOR CBRN

SCBA

Q- Use in conjunction with personal protective ensembles

that provide levels of protection against dermal haz-

ards.

R- Some CBRN agents may not present immediate

effects from exposure, but can result in delayed

impairment, illness, or death.

T- Direct contact with CBRN agents requires proper han-

dling of the SCBA after each use and between multi-

ple entries during the same use. Decontamination

and disposal procedures must be followed. If conta-

minated with liquid chemical warfare agents, dispose

of the SCBA after decontamination.

U- The respirator should not be used beyond 6 hours

after initial exposure to chemical warfare agents to

avoid possibility of agent permeation.

S - SPECIAL OR CRITICAL USER’S INSTRUCTIONS

1. Approved for use at temperatures above -25°F.

Approved only when the compressed-air container is

fully charged with air meeting the requirements of the

Compressed Gas Association Specification G-7 for

quality verification level (grade) D air or equivalent

specifications. The cylinder shall meet applicable DOT

specifications.

2. Do not alter this air mask. Altering will void the

Intrinsic-Safety rating and may affect the Intrinsic-

Safety of the device. Misuse or abuse of the heads-up

display system (FireHawk M7 Responder HUD),

FireHawk M7 Control Module, or FireHawk M7 Power

Module or using this equipment in a manner or situa-

tion not intended by the manufacturer, may result in

damage to the FireHawk M7 Responder HUD,

FireHawk M7 Control Module, or FireHawk M7 Power

Module, may result in personal injury or death to user

or persons dependent on the user. Always inspect the

FireHawk M7 Responder HUD for damage before use.

If damage is found, immediately remove the device

from service. The FireHawk M7 Responder HUD,

FireHawk M7 Control Module, and FireHawk M7

Power Module are approved intrinsically-safe and con-

form to UL/ANSI 913 for use in Class I, Div. I, Groups

C and D hazardous locations, temperature rating T3.

3. Use the air mask with adequate skin protection when

worn in gases and vapors that poison by skin absorp-

tion (for example: hydrocyanic-acid gas). In making

renewals or repairs, parts identical with those fur-

nished by the manufacturer under the pertinent

approval shall be maintained.

4. Approval for use against CBRN chemical warfare

agents is maintained only when using approved com-

ponents and following instructions listed on the

NIOSH approval supplement (P/N 10086012).

5. Do not mark the air mask, i.e., with stamps, labels,

paint, or other method. Use of such markings may

interfere with apparatus use or may constitute a flam-

mability hazard.

6. The mouth-bit can be inserted or removed from the

nosecup prior to use. See the “Preparing the

Respirator for Use” section for proper procedure.

2

TAL 803 (L) Rev. 1 - 10086011

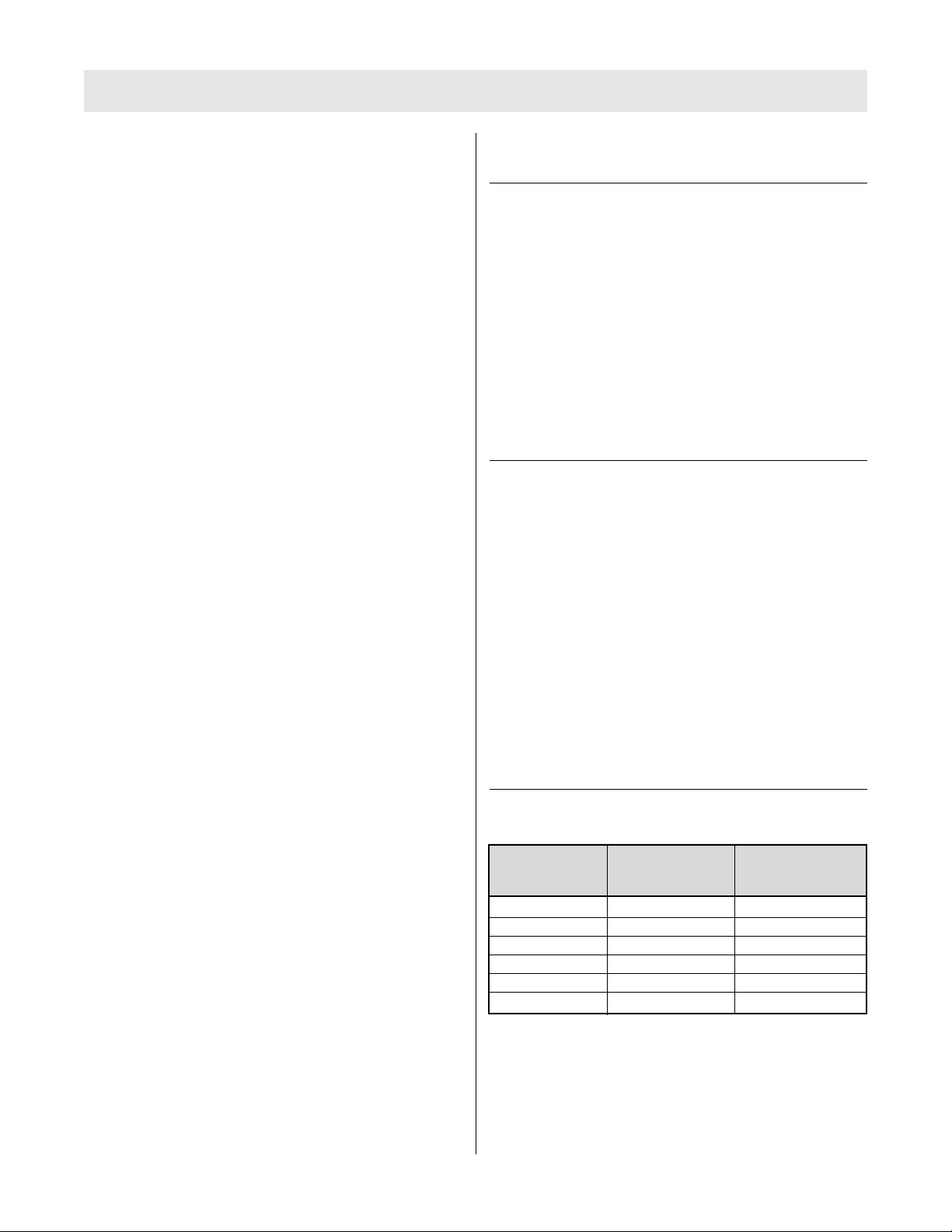

TABLE OF CONTENTS

NIOSH Approval Information.............................................2

Special or Critical Users Instructions................................2

Instructions for Use and Care ...........................................5

Description ........................................................................7

Visual Inspection and Functional Tests ...........................11

Size Selection..................................................................15

Respirator Fit Test ...........................................................15

Preparing Respirator for Use...........................................17

Donning ...........................................................................19

Using the Air Mask ..........................................................23

Cold Weather Operation..................................................29

URC Assembly Operation ..............................................31

Hydration System............................................................33

Removing the Apparatus.................................................35

Cleaning and Disinfecting ...............................................39

Flow Test and Overhaul Requirements ..........................41

FireHawk M7 Telemetry Module......................................43

Accessories .....................................................................47

Quick-Fill®System Operation..........................................49

Extendaire™ System......................................................53

Lifetime Warranty.............................................................55