DESCRIPTION

DESCRIPTION

The OptimAir 6A Powered Air-Purifying Respirator (PAPR)

is certified by the National Institute for Occupational

Safety and Health (NIOSH) as an air-purifying device

designed for use in atmospheres which are NOT immedi-

ately dangerous to life or health (IDLH).

Five models are available:

OptimAir 6A PAPR with high-efficiency particulate fil-

ter cartridges

OptimAir 6A PAPR with chemical cartridges

OptimAir 6A PAPR with combination cartridges

OptimAir 6A PAPR with CS/CN canisters

Advantage 3000 (Model 3100) full facepiece

The OptimAir 6A Particulate Filter Cartridge PAPR may be

used with the Comfo half-facepiece, Comfo Welder’s half-

facepiece, Comfo Elite half-facepiece, Comfo Elite

Welder’s half-facepiece, Ultravue full facepiece, Ultra Elite

full facepiece, Advantage 1000 full facepiece, Millennium

full facepiece, Advantage 3000 (Model 3100) full face-

piece, Tyvek, Saranex, or the Tychem QC Hoods.

The OptimAir 6A Chemical Cartridge PAPR may be used

with the Ultravue full facepiece, Ultra Elite full facepiece,

Advantage 1000 full facepiece, Millennium full facepiece,

Advantage 3000 (Model 3100) full facepiece, or Comfo-

style half-facepieces only.

The OptimAir 6A Combination Cartridge PAPR may be

used with the Ultravue full facepiece, Ultra Elite full face-

piece, Advantage 1000 full facepiece, Millennium full face-

piece, Advantage 3000 (Model 3100) full facepiece, or

Comfo-style half-facepieces only.

The OptimAir 6A CS/CN canister may be used with the

Millennium®or Advantage®1000 facepieces only.

Not : When the Advantage 1000 Facepiece is used, the

P/N 10012413 kit and P/N 96547 adapter must be

installed on the facepiece.

Not : When Millennium Facepiece is used, the P/N 96547

adapter must be installed on the facepiece.

COMBINATION CARTRIDGES

A combination cartridge consists of particulate filter media

and chemical sorbent in one cartridge package. This type

of cartridge must be used when harmful particulate matter

as well as harmful gases and/or vapors are present.

DO NOT us combination cartridg s with a PAPR

hood. Combination cartridg s ar approv d for us

with th Ultravu or Ultra Elit full fac pi c s or

Comfo-styl half-fac pi c s only. Failur to follow this

warning can r sult in s rious p rsonal injury or d ath.

CS/CN CANISTER

A CS/CN canister consists of particulate filter media and

chemical sorbent in one canister package. This type of

canister must be used when the CS/CN is present.

CS/CN canist rs ar approv d for us only with

Advantag 1000 or Mill nnium full fac pi c s. Failur

to follow this warning can r sult in s rious p rsonal

injury or d ath.

The Ultravue Facepiece and Ultra Elite Facepiece are

available with an integral welder's lens and are available

for use with the welder's adapter. All facepieces are avail-

able in small, medium, or large. Rubber or silicone materi-

al may be selected.

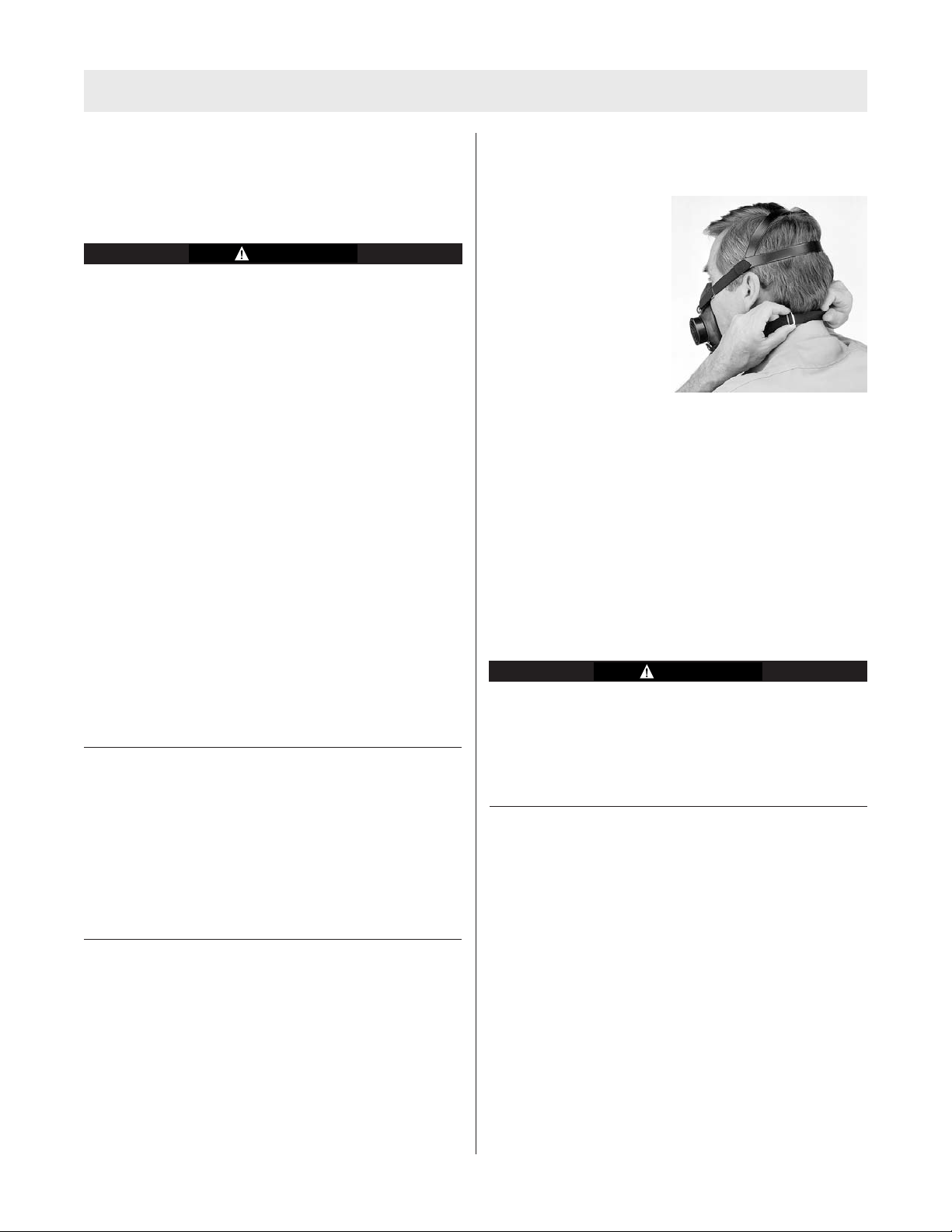

The motor-blower, battery pack, and filters are worn as an

assembly on the support belt. The breathing tube con-

nects the belt-mounted assembly to the facepiece or

hood.

The respirator may be used at temperatures between 0°

and 120°F, and may be worn under flame-retardant gar-

ments. If used below 40°F, a fully-charged NiCad Battery

may not operate the motor-blower for a shift.

PRINCIPLE OF OPERATION

The motor-blower draws surrounding air through cartridges

or canisters which capture the contaminants. Purified air

passes through the breathing tube to the facepiece or

hood. Air pressure in the facepiece or hood is higher than

the surrounding air. This means that if a small leak occurs,

air will flow from inside the facepiece or hood to the out-

side air. This is referred to as positive pressure. Air flow

also provides wearer comfort.

The OptimAir 6A PAPR is powered by a Nickel-Cadmium

(NiCad) or Lithium Battery Pack. The NiCad Battery Pack

only is rechargeable. The Lithium battery is NOT

rechargeable. However, the Lithium Battery has a very

long shelf life (up to 10 years).

The rechargeable Nickel-Cadmium Battery Pack and the

single-use Lithium Battery supplies 4.5 volts to the motor-

blower. The battery pack is replaceable. A fully-charged

NiCad Battery and a fresh Lithium Battery are designed to

operate for a shift. The battery pack is compatible with

both the standard and dual-rate (fast-rate) chargers.

5TAL 804 (L) Rev. 17 - 490883