MSA AUER

MSA Contents

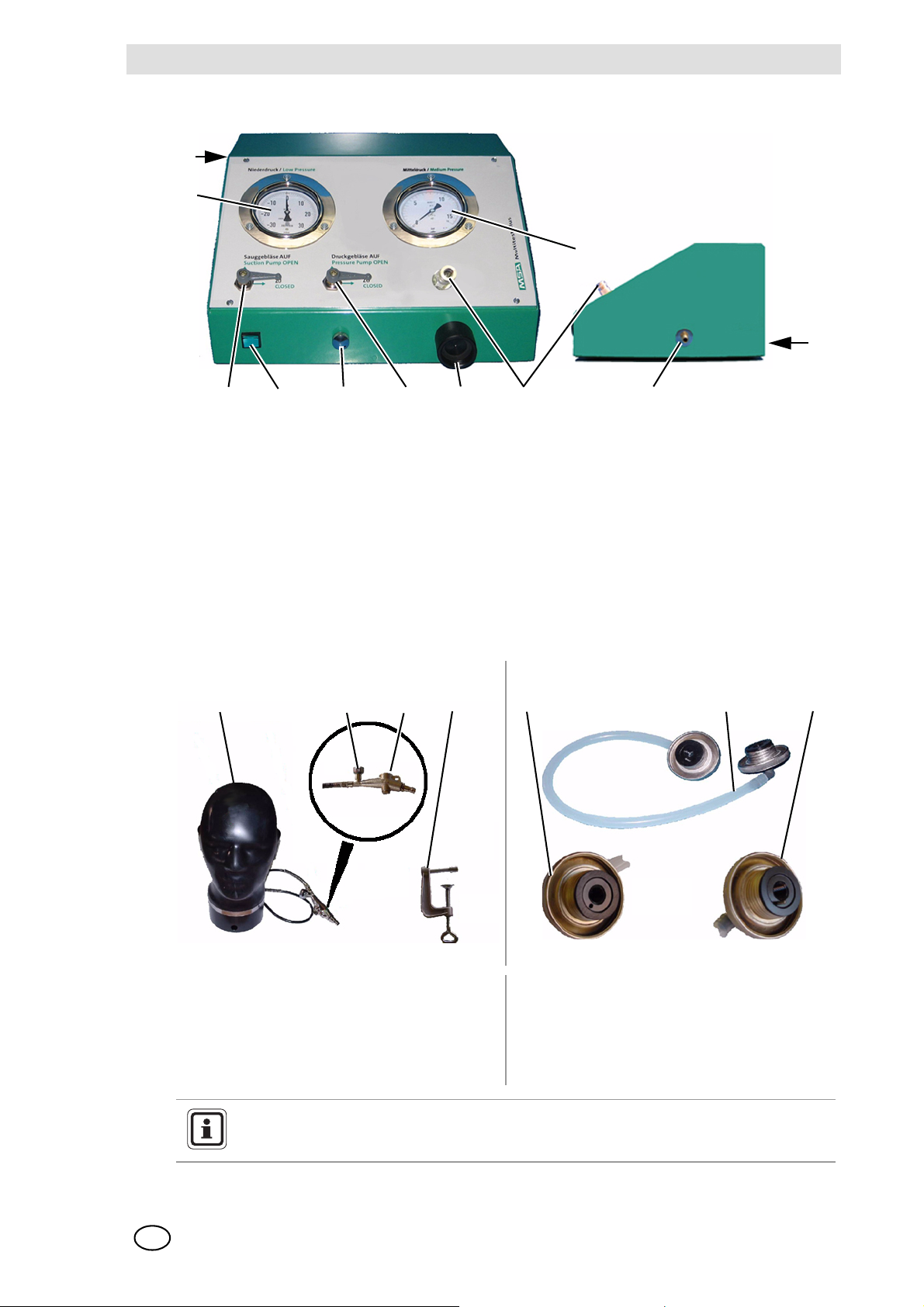

Multitest plus Console / Multitest plus Console 230 V 5

GB

Contents

1 Safety Regulations ....................................................................................................................... 6

1.1 Correct Use .......................................................................................................................... 6

1.2 Liability Information .............................................................................................................. 6

1.3 Safety and Precautionary Measures .................................................................................... 7

2 Description ................................................................................................................................... 8

2.1 Scope of Delivery ................................................................................................................. 8

2.2 Overview .............................................................................................................................. 8

2.3 Operating Elements ............................................................................................................. 9

2.4 Test Head .......................................................................................................................... 10

2.5 Test Head Maintenance ..................................................................................................... 11

3 Use ............................................................................................................................................... 11

3.1 Device Test ........................................................................................................................ 11

3.2 Activation ........................................................................................................................... 11

4 Testing Negative Pressure Devices ......................................................................................... 13

4.1 Lung Governed Demand Valve – Tightness Test without Medium Pressure .................... 13

4.2 Lung Governed Demand Valve – Tightness Test with Medium Pressure ......................... 14

4.3 Lung Governed Demand Valve – Opening Pressure ......................................................... 14

4.4 Medium Pressure – Tightness Test ................................................................................... 15

4.5 Mask - Tightness Test ........................................................................................................ 15

5 Testing Positive Pressure Devices ........................................................................................... 16

5.1 Lung Governed Demand Valve – Tightness Test without Medium Pressure .................... 16

5.2 Lung Governed Demand Valve – Tightness Test with Medium Pressure ......................... 17

5.3 Lung Governed Demand Valve – Closing Pressure .......................................................... 18

5.4 Medium Pressure – Tightness Test ................................................................................... 18

5.5 Mask - Tightness Test ........................................................................................................ 19

5.6 Mask - Opening Pressure of Exhalation Valve .................................................................. 19

6 Testing Chemical Protective Suit ............................................................................................. 20

6.1 Preparation ........................................................................................................................ 20

6.2 Stabilising the Chemical Protective Suit ............................................................................ 20

6.3 Chemical Protective Suit – Tightness Test ........................................................................ 21

6.4 Chemical Protective Suit – Valve Test ............................................................................... 21

7 Test Criteria for MSA Respiratory Protection Apparatus ....................................................... 22

8 Technical Data ............................................................................................................................ 22

9 Ordering Information ................................................................................................................. 23

9.1 Transition Adapters Mask / Lung Governed Demand Valves ............................................ 23

9.2 Transition Adapter for Chemical Protective Suit ................................................................ 24

9.3 Accessories ........................................................................................................................ 25