TL

v

Table of Contents

MODEL TL105 .........................................................................................................................I

TEST LAMP FOR FLAME DETECTION...................................................................................I

ABOUT THIS MANUAL........................................................................................................VIII

Format Conventions............................................................................................................viii

Notes, Cautions, and Warnings .................................................................................viii

Contacting Customer Support ...................................................................................viii

1.0 INTRODUCTION................................................................................................................9

1.1 Notice...................................................................................................................... 9

1.2 Sp ec ial Warnings ...................................................................................................... 9

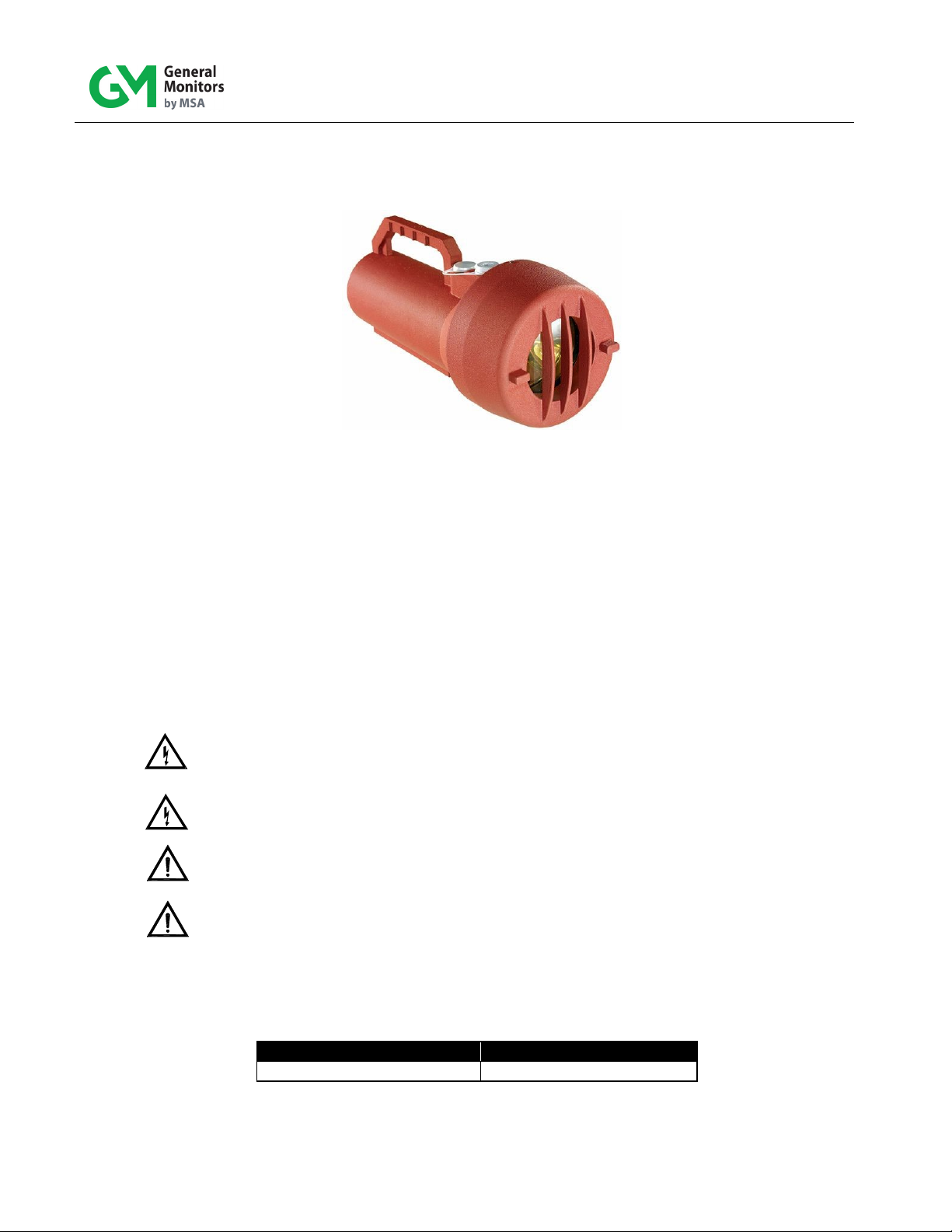

1.3 D esc rip t io n............................................................................................................. 10

1.4 Upo n Rec ei vi ng....................................................................................................... 10

1.5 Tes t Lamp Operating Principle .................................................................................. 11

2.0 QUICK START GUIDE.....................................................................................................12

3.0 TEST LAMP COMPONENTS...........................................................................................13

3.1 Lamp Housing A ss emb ly .......................................................................................... 13

3.2 Microcontroller........................................................................................................ 13

3.3 Rotary Switch Setting............................................................................................... 13

3.4 Rechargeabl e B at tery .............................................................................................. 13

3.5 Power Jack ............................................................................................................ 13

3.6 Push Button............................................................................................................ 13

3.7 Aluminum Cas e and Cap .......................................................................................... 14

3.8 Battery Charge State Indicator................................................................................... 14

4.0 USE AND OPERATION...................................................................................................15

5.0 TEST LAMP MAINTENANCE AND WARRANTY.............................................................18

5.1 Maintenance........................................................................................................... 18

5.2 Cleaning the S app hi re Windo w.................................................................................. 18

5.3 Recharging the Battery............................................................................................. 19

5.4 Obtaining Service.................................................................................................... 19

5.5 Warranty................................................................................................................ 19

6.0 TROUBLESHOOTING GUIDE.........................................................................................21

CUSTOMER SUPPORT...................................................................................................22

7.0 22

7.1 Other Sources for Help............................................................................................. 22

8.0 APPENDIX ......................................................................................................................23