High Pressure Housing

Operation Manual

I2 I

Safety Instructions

The sensor must only be used according to the Ex certificates listed

below. See product name plate for actual approvals.

To reduce risk of ignition in hazardous atmospheres, disconnect the

equipment from the supply circuit before opening. Keep assembley

tightly closed when in operation. For use according to UL-listing, con-

duit seals must be installed within 18" distance of the inclosure sensor

must be connected to a Class 2 power supply. The housing parts must

be kept as one unit.

They are not interchangeable with parts from similar housings. Only

tools applicable for use in explosive atmosphere must be used. When

mounting the rod in “ZONE 0” it is necessary to prevent any leakage

between “ZONE 0” and the surrounding environment. The sensor

house must be connected to an equipotential bonding system or an

earthing system.

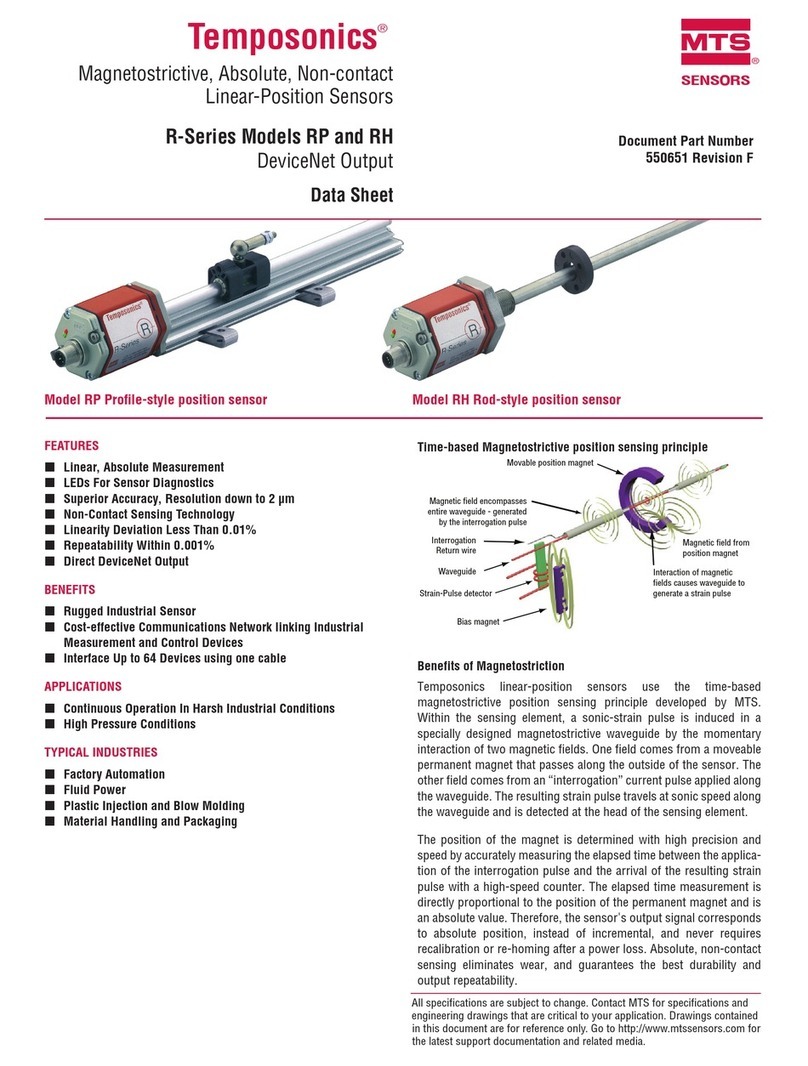

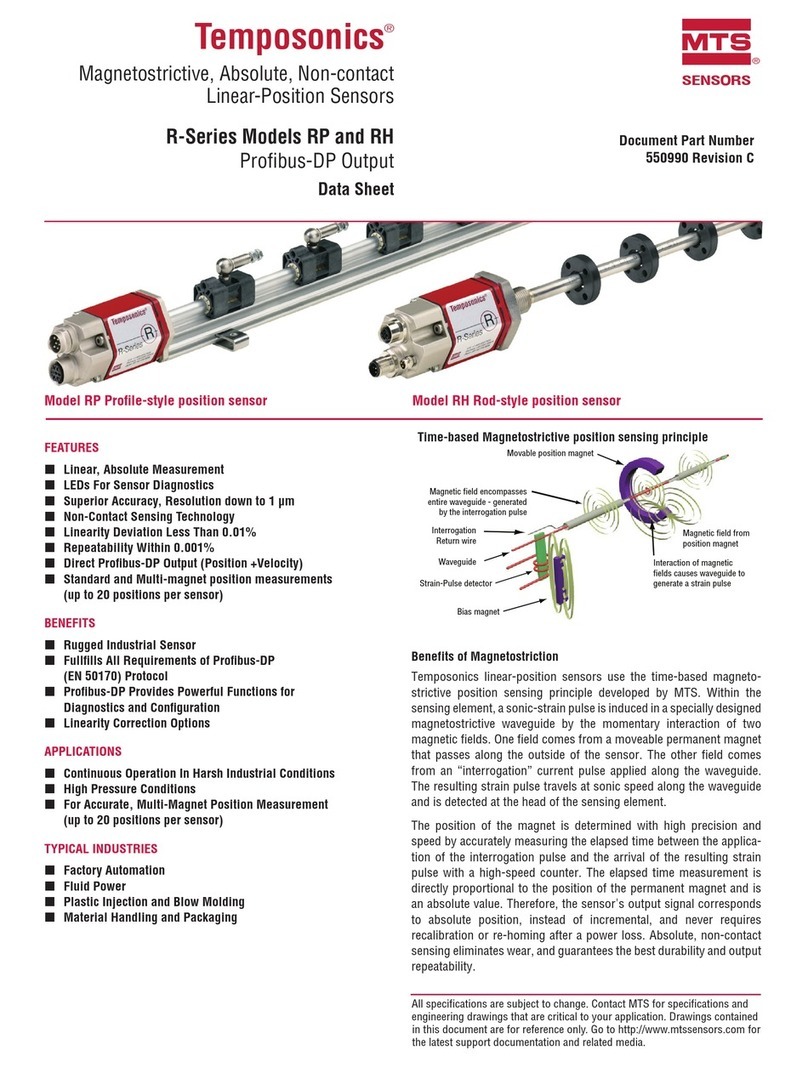

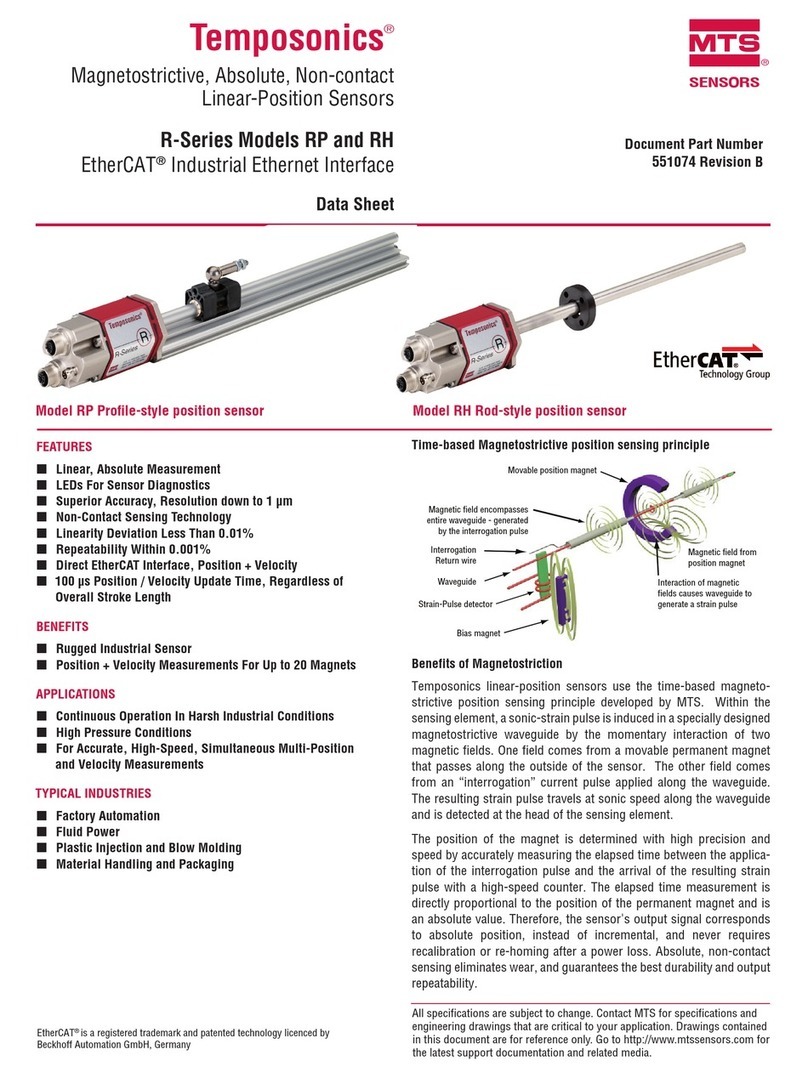

PRECISION POSITION MEASUREMENT – HPH

This High Pressure Housing (HPH) is ATEX/IECEx as well as UL and

cUL approved for use in hazardous locations with Temposonics®

position sensors. The ATEX /IECEx, UL and cUL approvals cover flam-

mable gases, vapors, liquids and dust.

This housing is made to fit Temposonics®G-Series Analog + Start/Stop

Sensors and R-Series sensors with analog and digital outputs. Both

fixed cable and connector versions can be used. When using a standard

sensor in this housing you get a cost efficient solution for use in haz-

ardous locations which also allows easy sensor replacement. Several

design combinations are available to fit your application:

M18 or ¾"UNF mounting flange - M20 or ½" NPT cable gland thread -

top mounted or single/dual side-mounted. See combination chart. All

parts are made of 316L stainless steel. The housing is also available in

non-approved versions ensuring an outstanding protection to the sen-

sor when used in rigged applications with high humidity and agressive

gases.

TECHNICAL DATA

Explosion protection

ATEX, IECEx II 2G Ex db IIC T5 Gb Tamb −40°C to +75°C

II 2D Ex tb IIIC T100°C Db

ATEX: ExVeritas 16 ATEX 0192X

IECEx: IECEx EXV 16.0014X

In accordance with EN 60079-0, EN 60079-0, EN 60079-1, 60079-26 and EN 60079-31

Only with ATEX approved cable glands (Ex d)

Classication

Class 1, Devision 1, Groups A, B, C, and D hazardous areas, temperature class T5

Certied to re, electrical shock and explosion hazards according to UL no. 2PD0.

In accordance with UL 1203 standard.

Only with UL approved cable glands

Operating conditions

Operating temperature 1−40…+75 °C (−40…+167 °F)

Humidity 90 % relative humidity, no condensation

Ingress protection IP68 (only with IP68 approved cable gland)

Magnet movement velocity Any

Design/Material

Sensor rod Stainless steel 1.4404 (AISI 316L)

Cable gland threads M20×1.5 or ½" NPT

Stroke length 50…7500 mm

Mechanical mounting

Mounting ange M18×1.5 or ¾" - 16UNF - 3A

Mounting instructions Please consult the technical drawings and the operation manual (document no.: 551751)

Approved sensors

Temposonics® position sensors G-Series Analog+Digital

R-Series Probus

R-Series CANBUS

R-Series DeviceNet

R-Series V Analog

R-Series VSSI

1/ Tamb+ is limited to max Tamb+ of used sensor −10 ºC (−14 ºF)