MTS Sensors

R-Series Models RP and RH Temposonics®Linear-Position Sensors - Analog Outputs

Product Data Sheet, Document Part No.: 550992 Revision E (EN) 05/2014 2

Product specifications

Product overview

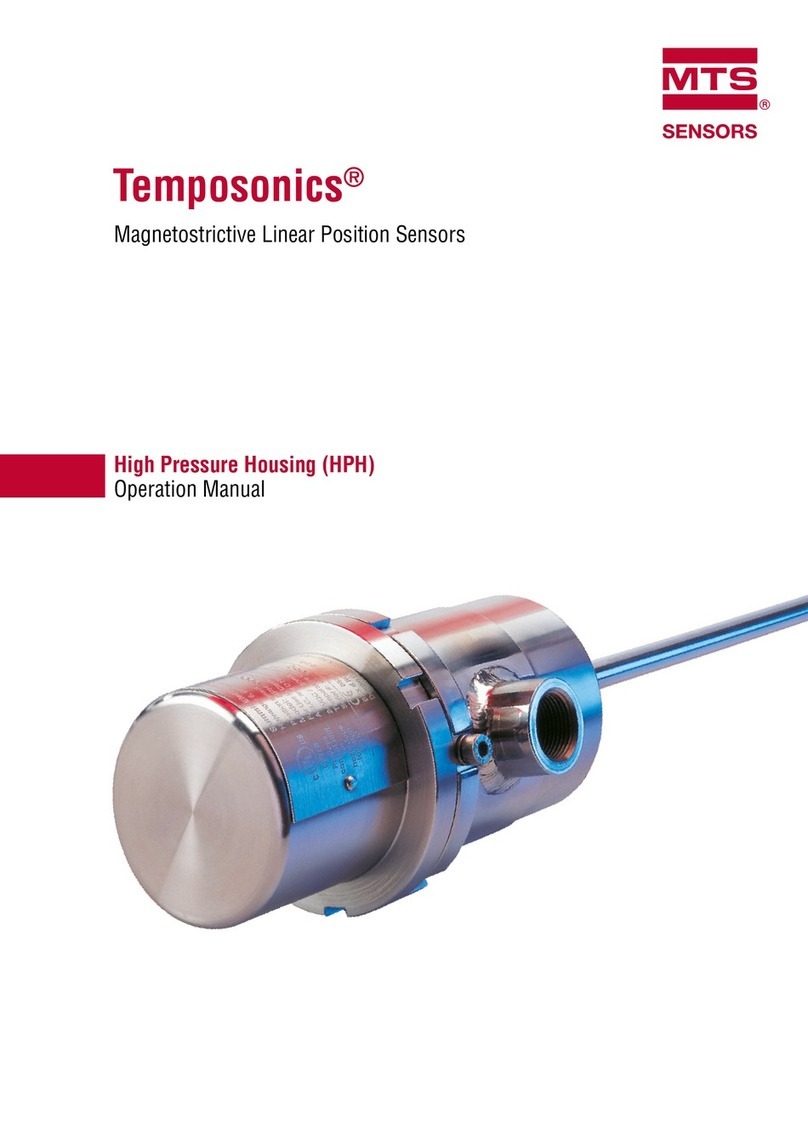

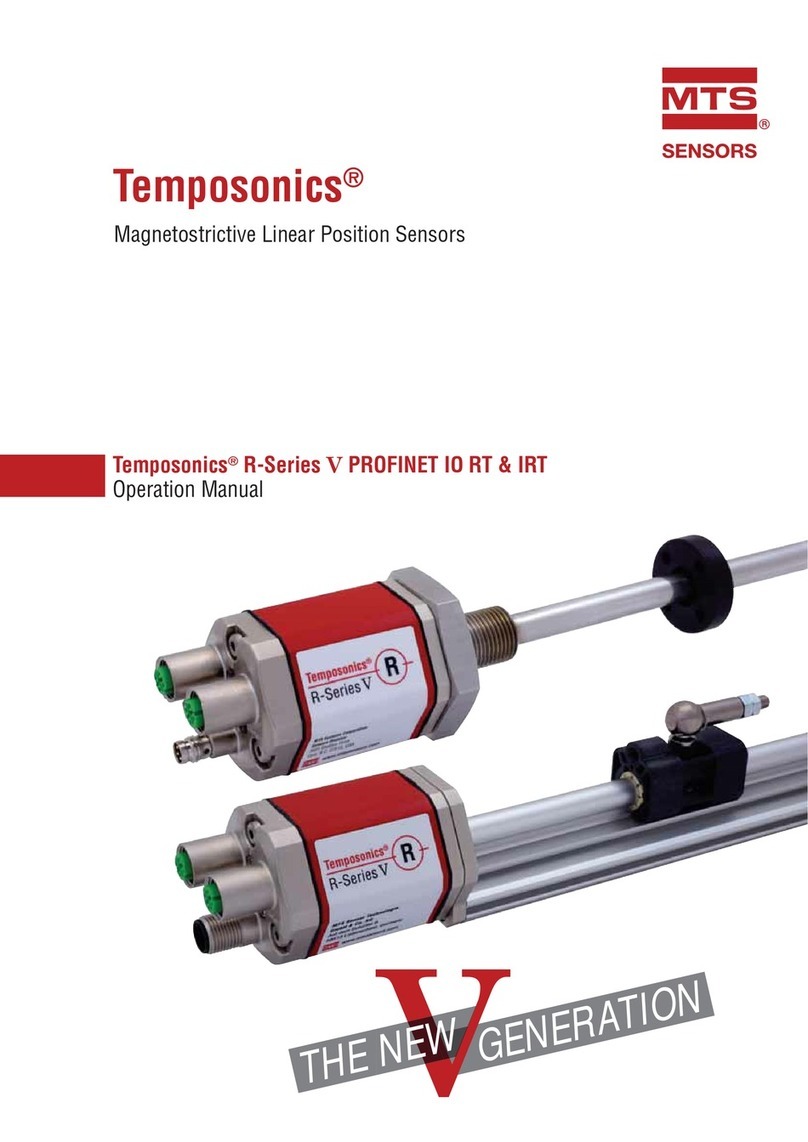

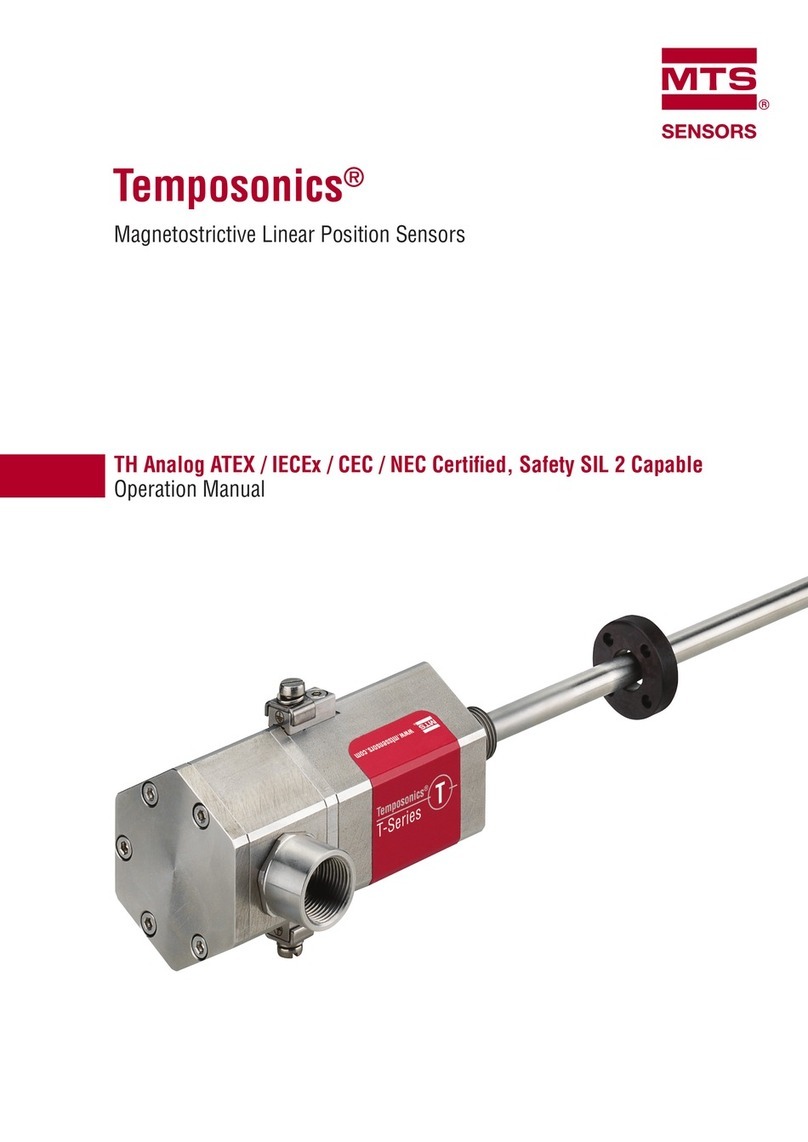

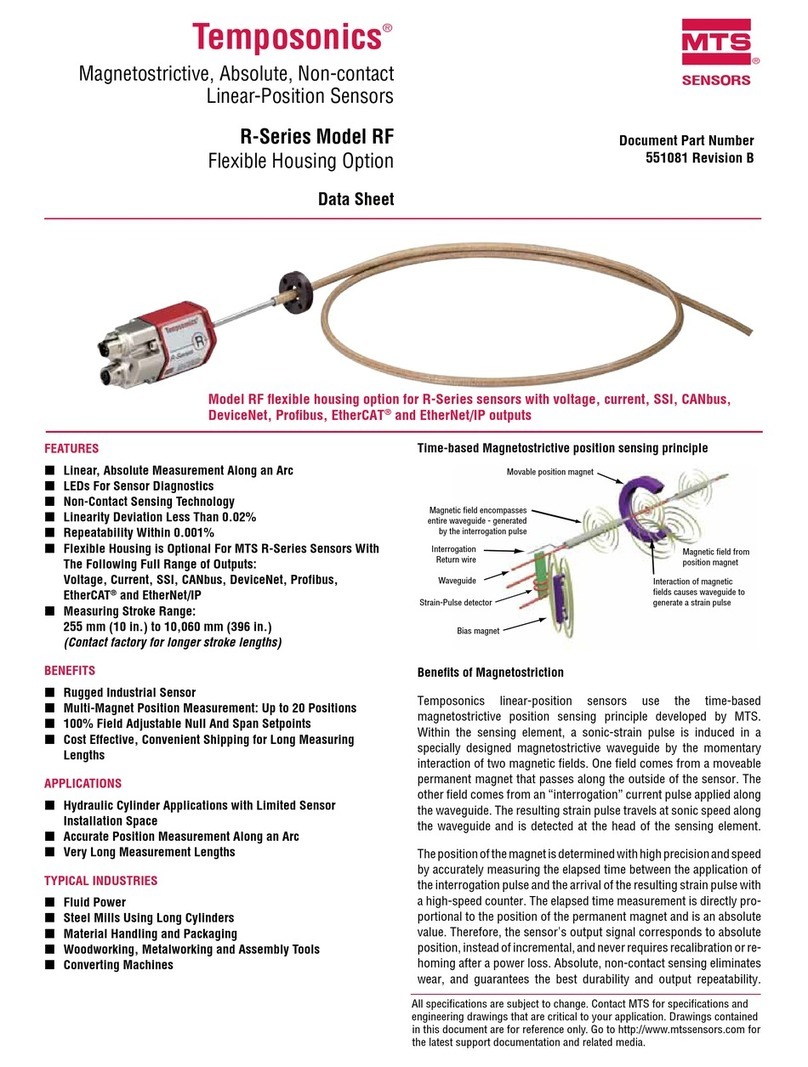

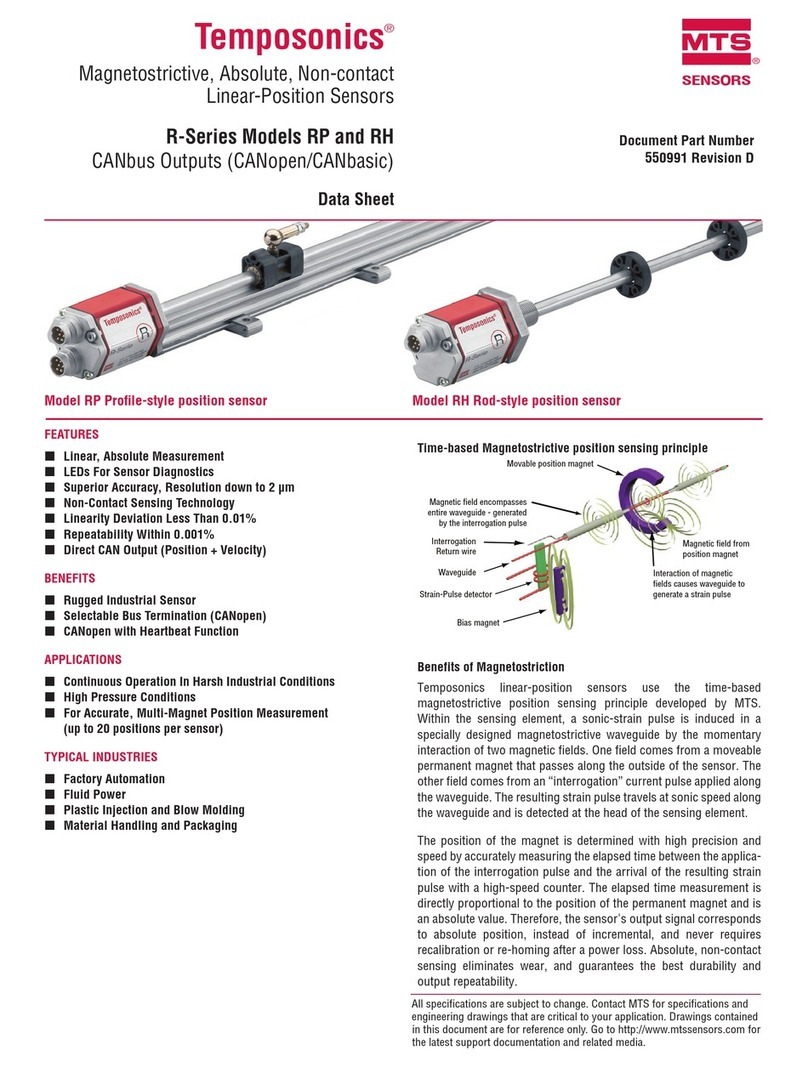

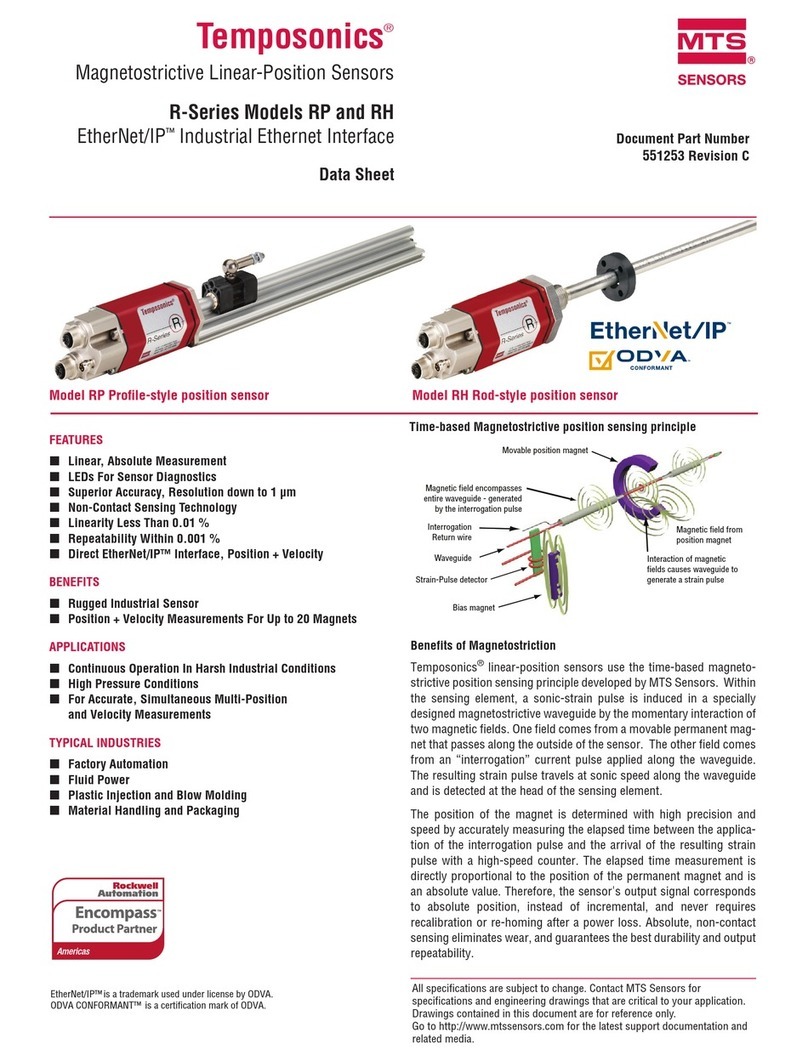

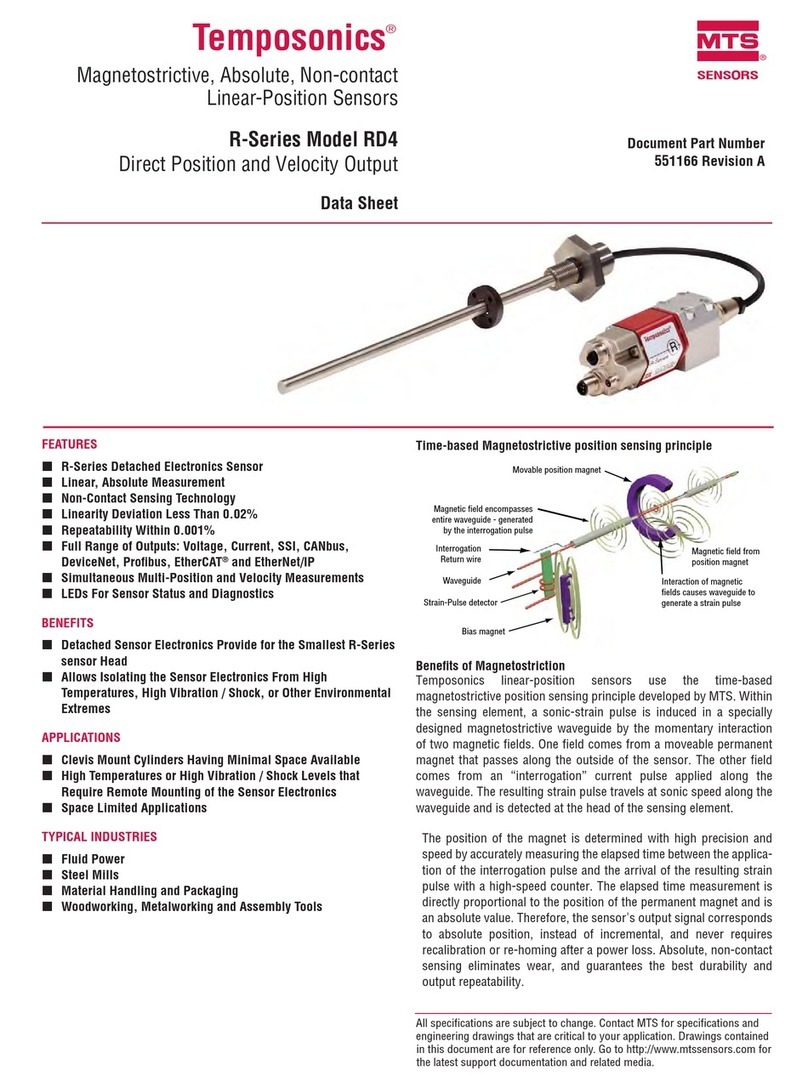

R-Series model RH and RP sensors are extremely robust and are ideal for continuous operation under harsh industrial conditions. MTS offers

two standard sensor housings, rod and profile extrusion. The rod housing is capable of withstanding high pressures such as those found

in hydraulic cylinders. The profile extrusion housing provides convenient mounting options and captive sliding magnets which utilize slide

bearings of special material that reduce friction, and help mitigate dirt build up. The sensor head contains the active signal conditioning and a

complete integrated electronics interface. Double shielding is used to ensure EMI protection for unsurpassed reliability and operating safety.

Parameters Specifications

ENVIRONMENTAL

Operating

conditions:

Operating temperature:

-40 °C (-40 °F) to +75 °C (+167 °F)

Relative humidity: 90% no condensation

Temperature coefficient: < 30 ppm/ °C

EMC test: Electromagnetic emission:

IEC/EN 50081-1

Electromagnetic susceptibility:

IEC/EN 50082-2, IEC/EN 61000-4-2/3/4/6,

level 3/4 criterium A, CE qualified

Shock rating: 100 g (single hit)/

IEC standard 68-2-27 (survivability)

Vibration rating: 15 g (30 g with HVR option)/10 to 2000 Hz,

IEC standard 68-2-6 (operational)

WIRING

Connection type: 6-pin male D60 (M16) connector or

integral cable

PROFILE STYLE SENSOR (MODEL RP)

Electronic head: Aluminum housing with diagnostic LED

display

(LEDs located beside connector/cable exit)

Sealing: IP 65**

Sensor extrusion: Aluminum (Temposonics profile style)

Mounting: Any orientation. Adjustable mounting feet

or T-slot nut (M5 threads) in bottom groove

Magnet types: Captive-sliding magnet or open-ring

magnet

ROD STYLE SENSOR (MODEL RH)

Electronic head: Aluminum housing with diagnostic LED

display

(LEDs located beside connector/cable exit)

Sealing: IP 67 or IP 68 for integral cable models**

Sensor rod: 304L stainless steel

Operating

pressure:

350 bar static, 690 bar peak

(5000 psi static, 10,000 psi peak)

Mounting: Any orientation. Threaded flange M18 x 1.5

or 3/4 - 16 UNF-3A

Typical

mounting torque: 45 N-m (33 ft. - lbs.)

Magnet types: Ring magnet, open-ring magnet, or magnet

float

Product Overview and Specifications

Parameters Specifications

OUTPUT

Measured output

variables:

Position + speed (magnitude) or velocity

(with direction) for single or dual magnets

Resolution: Position measurement:

16 bit; 0.0015% (minimum 1 µm)

Speed measurement:

0.1 mm/s

Linearity

deviation: < ± 0.01% full stroke

(minimum ± 50 µm)

Repeatability: < ± 0.001% full stroke

(minimum ± 2.5 µm)

Hysteresis: < 4 µm

Analog Outputs: Voltage:

0 to 10, 10 to 0, -10 to +10, +10 to -10

Vdc (minimum controller load >5k ohms)

Current:

4(0) to 20 mA, 20 to 4(0) mA

(minimum/maximum load 0/500 ohms)

Stroke lengths: Range (Prole style):

25 to 5080 mm (1 to 200 in.)

Range (Rod style):

25 to 7620 mm (2 to 300 in.)

Update times:

0.5 ms up to 1200 mm, 1.0 ms up to

2400 mm, 2.0 ms up to 4800 mm, 5.0 ms up

to 7620 mm stroke length

Speed

measurement:

Range:

0.025 - 10 m/s (1.0 - 400.0 in./s)

Deviation: <0.5%

Resolution:

0.1 mm/s (0.004 in./s)

Update time:

Refer to update times in

'Position measurement' above

ELECTRONICS

Operating

voltage: +24 Vdc nominal: -15% or +20% *

Polarity protection: up to -30 Vdc

Over voltage protection: up to 36 Vdc

Current drain: 100 mA typical

Dielectric withstand voltage: 500 Vdc

(DC ground to machine ground)

Setpoints:

Setpoint adjustment (Null/Span):

100% of electrical stroke length. 25 mm

(0.98 in.) min. distance between setpoints.

For dual-magnet outputs:

76 mm (3 in.) min. distance between

magnets

* UL Recognition requires an approved power supply with energy limitation UL 61010-

1), or Class 2 rating according to the National Electrical Code (USA) / Canadian

Electrical Code.

** The IP rating is not part of the UL Recognition.