NEC FDl165 Technical specifications

Other NEC Computer Hardware manuals

NEC

NEC V850/SF1 User manual

NEC

NEC DS2000 IntraMail How to use

NEC

NEC N8105-53 User manual

NEC

NEC VR4133 Guide

NEC

NEC IE-178048-NS-EM1 User manual

NEC

NEC N8103 Series Operating instructions

NEC

NEC IE-789882-NS-EM1 User manual

NEC

NEC IE-V850ES-G1 User manual

NEC

NEC QB-MINI2 User manual

NEC

NEC N8151-53 User manual

NEC

NEC N8160-85 User manual

NEC

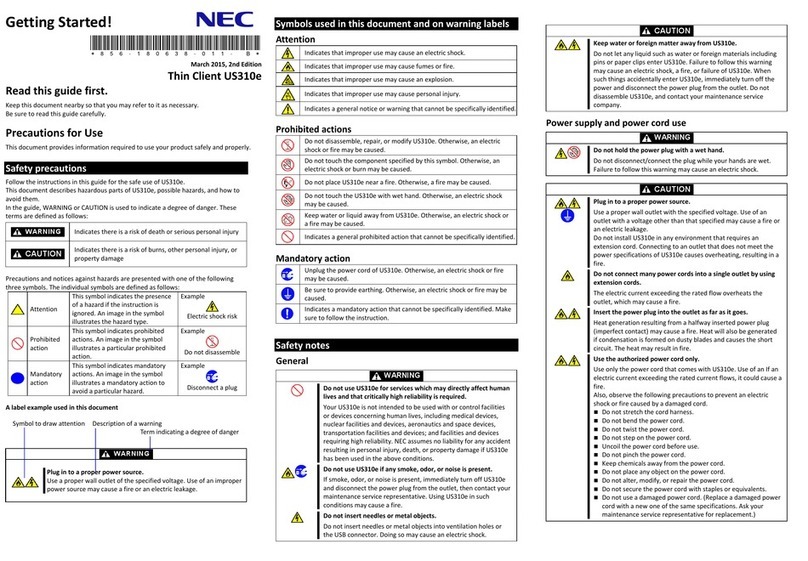

NEC Thin Client US310e User manual

NEC

NEC N8115-13 User manual

NEC

NEC NEC PD78081(A) User manual

NEC

NEC NEAX 2400 User manual

NEC

NEC TTS 58AXPJ User manual

NEC

NEC IE-784000-R User manual

NEC

NEC SB3-DB1 User manual

NEC

NEC Express 5800 120Eg User manual

NEC

NEC N8104-125A User guide

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual