PTS

8

A lockable safety switch is recommended for

the electrical system including the fan.

Before installation

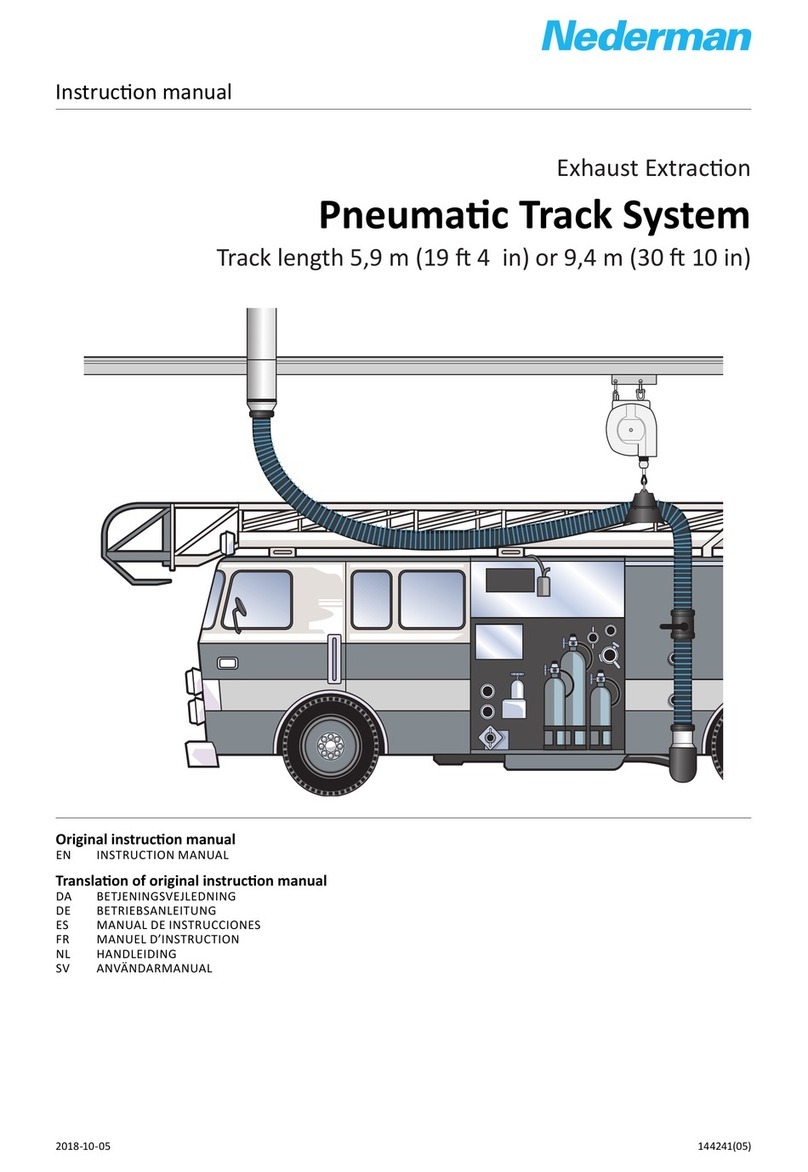

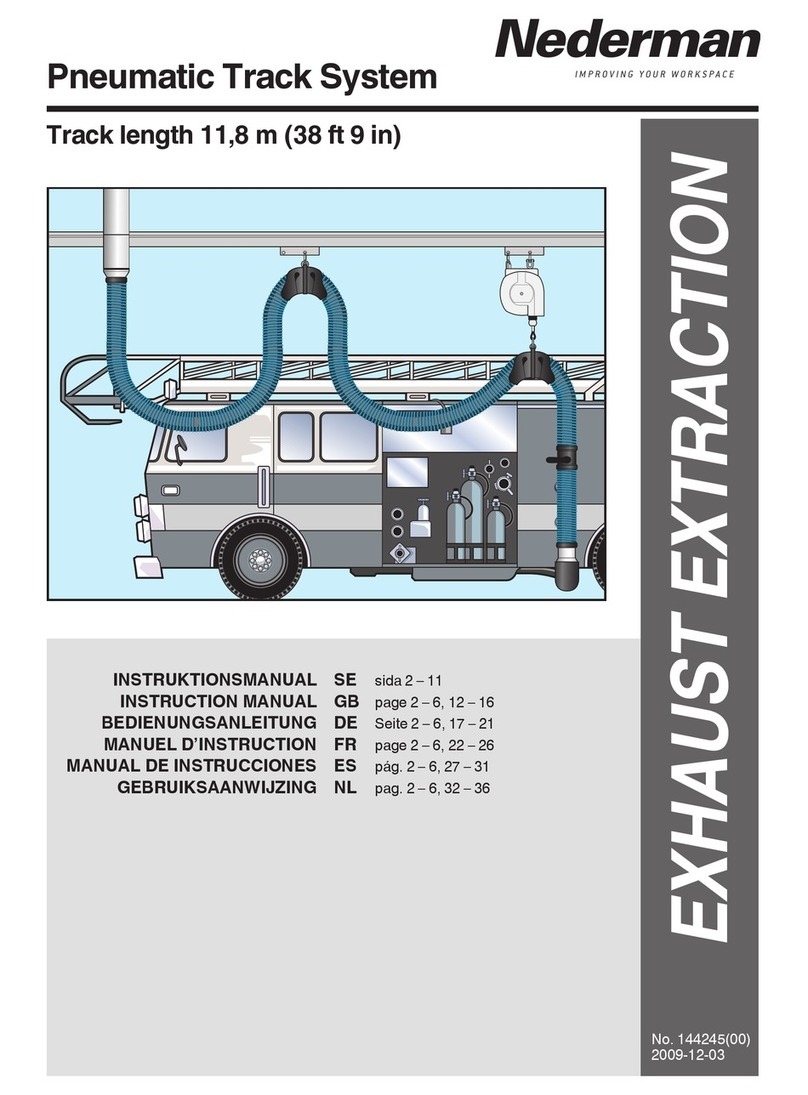

Before the PTS system can be installed, a suitable

position must be determined in relation to the vehicle's

parking position in the station. N.B. The vehicle’s par-

king position must be on the opposite side

of the track compared to the duct connection.

See picture Alternative 1 / 2.

The distance from the oor to the bottom edge of the track

should normally be 10 - 13 ft (3 - 4 m). 11 ft 6 in (3,5 m)

is recommended. If the system is to be used between two

vehicles, the distance between the vehicles must be at

least 4 ft (1,2 m).

The distance from the track's front edge to the station

door threshold should be at least 3 ft (1,0 m). Make

sure the door can open freely without interference to

the track. See picture A.

Installation instructions

See pictures 1 - 14.

1. Place all the track proles in line with each other

on the oor according to the picture. Screw the proles

together with the lengthening joints.

2. Fasten the mounting brackets on the proles

according to the measurements in the picture.

3. Lift the tracks and t them in the ceiling. Check that

there is no gap between the track sections. The

mounting devices should be xed in bars, brackets or

similar arrangements according to the examples.The

rst and the last mounting bracket should be braced

(see pictures Aand B). All mounting brackets should

be braced with bracing bars positioned sideways ac-

cording to one of the pictures C,D or E. When moun-

ting the track, ensure that suitable xing bolts are used

considering the ceiling construction material and the

traction forces in the suspension points.

4. Position the duct connector near the middle of the

main track. Fasten it according to 12 a - e. NB! The

duct connector must not be positioned on the

same side of the track as the vehicle's parking

position (see picture Alternative 1 / 2).

5. Connect the nozzle kit on the safety

coupling.

6. Slide the trolley with balancer into the main track.

7. Fit the balancer cord in the sheet metal bend.

8. Mount the trolley with hose holder in the

secondary track. Fit the hose holder on the hose

minimum 12 ft 6 in (3,8 m) from the balance cord (see

picture 9).

The exhaust hose length is delivered for a mounting

height of 11ft 6 in (3,5 m). It is important that

the nozzle suspends freely (approx. 1 ft (30 cm))

from the oor when the hose is in its raised

position. For higher mounting heights than 11 ft 6 in

(3,5 m) the hose position is adjusted by moving the

balancer cord stop the necessary length. For lower

mounting heights than 11 ft 6 in (3,5 m) the exhaust

hose must be cut in the following way:

a. Separate the safety coupling.

b. Close the compressed air supply.

c. Cut o the necessary length of the lower

exhaust hose.

d. Cut the compressed air hose by the same length

as the exhaust hose.

e. Reassemble the hose and the safety coupling.

f. Check that there is no tension in the hose after

the nozzle has been connected to the exhaust pipe.

9. To obtain clearance height under the exhaust

hose (when the vehicle is in parking position) the

position of the duct connector must be adjusted in

the following way (see picture 9 a - e):

a. Back the vehicle into its parking position.

b. Slide the exhaust nozzle onto the exhaust pipe

of the vehicle.

c. Loosen the duct connector from the exhaust track

and push it towards the door opening and the track´s

front edge, until the distance from the oor to the bottom

edge of the exhaust hose is at least 7 ft (2,1 m).

d. Drill holes, diameter 2/5 in (10 mm) in the track

for the duct connector bracket. It is to be noted that

the duct connector must be fastened in front of the

middle of the track.

e. Fasten the duct connector with screws.

10. Install shock absorbers in the front edge of the tracks.

11. Install screw and nut at the back edge of the tracks.

12. Install the disconnection valve on the front part

of the main track. Install the valve with the screw X.

Max. moment = 1,1 lbft (1,5 Nm). The exact distance

from the front edge of the track must be checked acc.

to the installation protocol point 3F.

13. Install the compressed air hose to the T-coupling.

The hose is mounted on the top of the guide track. Drill

holes, 1/6 in (4,5 mm) diameter, and t the hose with

clips according to the pictures. Adjust the hose length

and connect the hose to the disconnection valve.

14. A exible hose, minimum length 1 ft (30 cm) must

be connected between the duct connector and the

duct pipe work.

Fans

Fans are not included in the basic package. For the

best results, one fan per extraction unit is recom-

mended. It is also possible to connect several units

to a central fan.

To obtain optimum performance, the fan should be

positioned as near the duct outlet from the room as

possible. Please contact your Nederman represen-

tative for advice on fan selection.

The exhaust pipe

The edge of the exhaust pipe must have a free

distance to surrounding vehicle parts. See recom-

mendations, picture C. Check that the nozzle, after the

disconnection, does not catch any part of the vehicle.

It is possible that modications may be required to the