netvox R718VA User manual

Other manuals for R718VA

1

Table of contents

Other netvox Accessories manuals

netvox

netvox R718PA7 User manual

netvox

netvox RB11E User manual

netvox

netvox R711 User manual

netvox

netvox R72616A User manual

netvox

netvox R718EA User manual

netvox

netvox R718PA Series User manual

netvox

netvox Z311C User manual

netvox

netvox R718F2 User manual

netvox

netvox R718AD User manual

netvox

netvox RA0723 User manual

netvox

netvox R718PA11 User manual

netvox

netvox R311DB User manual

netvox

netvox R718DB User manual

netvox

netvox R311FA User manual

netvox

netvox RA0716 User manual

netvox

netvox R718PA4 User manual

netvox

netvox R718PA22 User manual

netvox

netvox ZigBee ZB11B User manual

netvox

netvox R718E User manual

netvox

netvox R718EB User manual

Popular Accessories manuals by other brands

Generac Power Systems

Generac Power Systems Air-Cooled Generator Sets 5621 specification

Emos

Emos P5525 manual

RS Barcelona

RS Barcelona You and Me user manual

Bosch

Bosch Rexroth ActiveMover Assembly instructions

Simrad

Simrad PI REMOTE - QUICK REFERENCE GUIDE REV B Quick reference guide

Ursalink

Ursalink AM100 Series Configuration guide

Crestron

Crestron GLS-LCL Installation and operation guide

NK TECHNOLOGIES

NK TECHNOLOGIES AG1 Series instructions

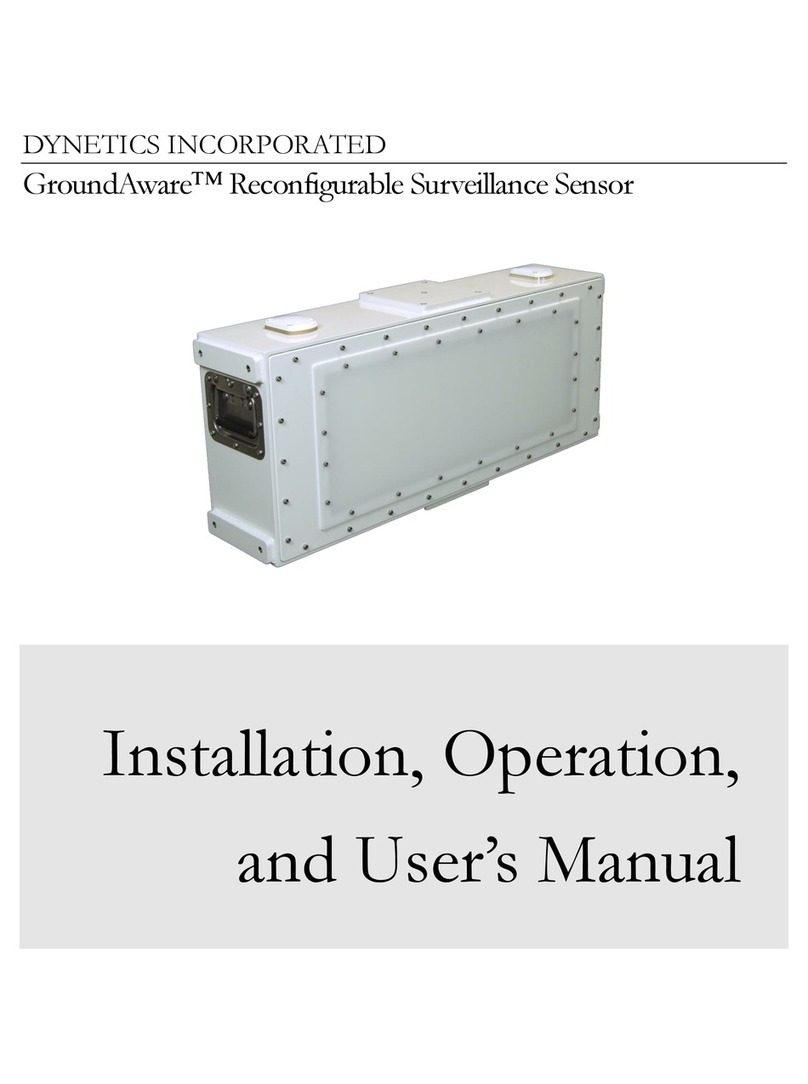

DYNETICS INCORPORATED

DYNETICS INCORPORATED GroundAware user manual

MojiLife

MojiLife AirMoji II instructions

THORLABS

THORLABS WFS20-5CM Operation manual

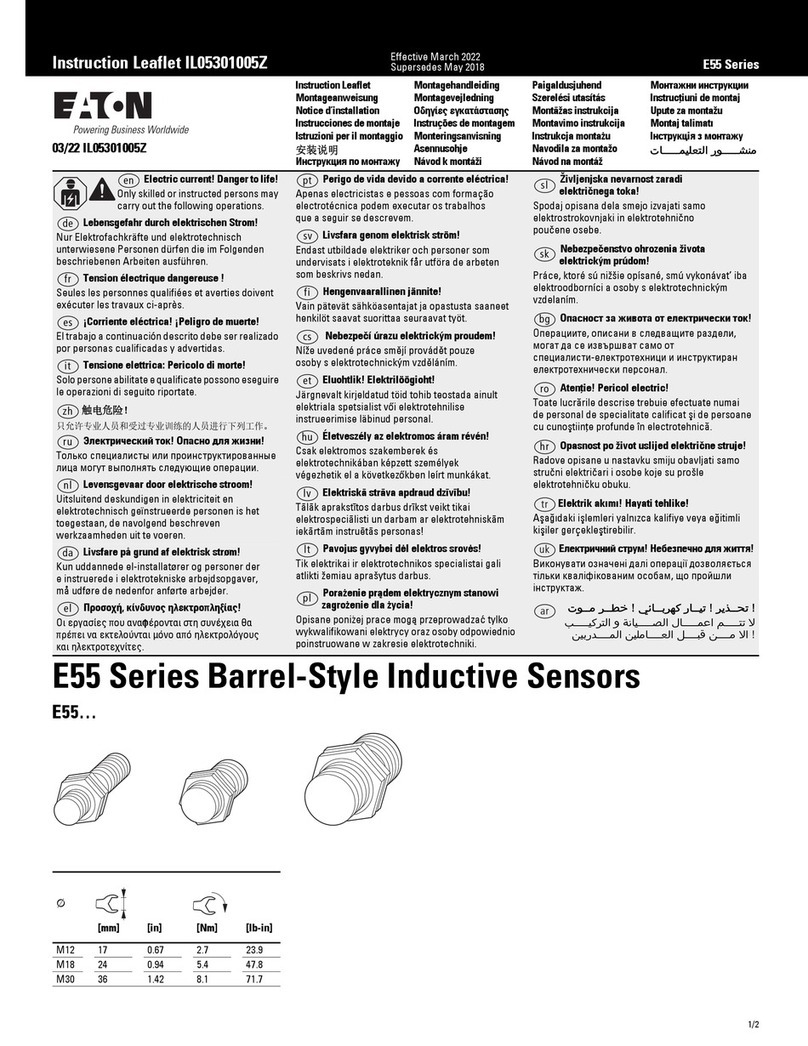

Eaton

Eaton E55 Series Instruction leaflet

PCB Piezotronics

PCB Piezotronics IMI SENSORS 080A122 Installation and operating manual

Panasonic

Panasonic HL-C211F instruction manual

Digitus

Digitus DS41211 user manual

PCB Piezotronics

PCB Piezotronics 377A07 Installation and operating manual

Sygonix

Sygonix 2612693 operating instructions

Dudek

Dudek Light 90/110 user manual