Page | 4

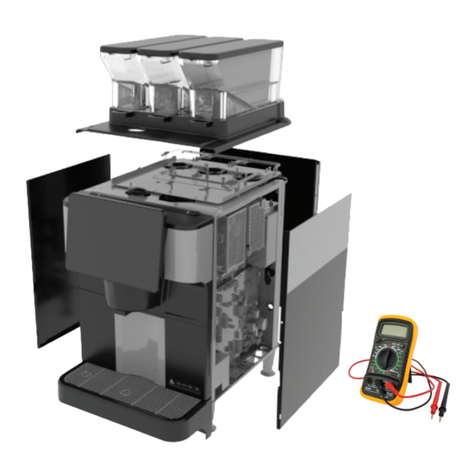

TROUBLE SHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE WHAT TO CHECK REMEDY

CAN’T START BREW CYCLE 1. No Water

2. No Power

3. On/Off Switch

4. Brew Start Switch

5. Timer/Timer Harness

Timer/Probe & Harness

6. Solenoid Valve

1. Water bottle is empty?

2. Fuse or circuit breaker,

power cord & plug

connections

3. Switch continuity [normally

closed 1 & 2]

4. Switch continuity [normally

open]

5. Leads to solenoid, switches,

& level sensor probe.

6. (A) Voltage at solenoid

valve terminals, start a brew

cycle & check for 120V AC

(B) If voltage is present at

terminals, check water on

the inlet side of solenoid

valve

1. Replace empty bottle with

new one

2. Replace or reset circuit

protector as required, unit

should be plugged in

securely

3. If On/Off switch does not

make and break contact

replace it

4. If brew start switch does not

make & break contact,

replace it

5. Make sure these

connections are tight, if all

checks out ok replace timer

6. (A) If voltage is not present

at terminals, refer to steps 2

thru 5 (B)If voltage is

present at terminals, water

is present at the inlet side

but not at the outlet side of

the solenoid valve replace it

NO HOT WATER 1. Tank heater

2. Hi-limit thermostat or main

thermostat

1. Check voltage at the tank

terminals, voltage should be

as indicted on the serial tag

2. Check voltage between the

white wire on the tank &

incoming terminal [blue

wire] on the hi-limit

thermostat, then the

outgoing terminal [black

wire] on the hi-limit

thermostat

1. (A) If correct voltage is

present at the tank heater

terminals & water not

heated, replace the tank’s

heating element (B) If

voltage is not present at the

tank heater terminals refer

to step 2 (c) if incorrect

voltage is present at the

tank heater terminals, check

voltage at outlet

2. (A) If voltage is present on

the incoming terminal of the

hi-limit thermostat, but not

on the outgoing terminal,

replace the hi-limit

thermostat (B) Check the

voltage between the black &

white wire on the

receptacle, if voltage is not

present check outlet or

circuit breaker (C) If voltage

is not present on the

incoming terminal of the hi-

limit thermostat replace the

main the main thermostat

STEAMING/SPITTING

AROUND FUNNEL

1. Main Thermostat

2. High Altitude

1. Thermostat points stuck or

out calibration

2. Located above 5,000 feet

1. (A) Adjust thermostat (B)

Thermostat should be

calibrated or replace

2. See installation instructions

FAUCET WATER TOO SLOW 1. No Water 1. (A) Water bottle (B) Faucet

clogging

1. (A) Replace empty bottle

with new one (B) Clean or

rebuild faucet

DRIPPING 1. Not siphoning properly 1. Water should flow freely

from the spray head

1. (A) Clean spray head holes

(B) Check tightness of spray

head tube

DRY COFFEE REMAINING IN

BREW BASKET AFTER

BREWING

1. Filter

2. Not siphoning properly

3. Improper loading of brew

basket

1. Correct filters being used?

2. Refer to “Dripping” step 1

3. Filter & coffee in brew

basket

1. Insert proper filter

2. Refer to “Dripping” step 1

3. Filter centered, coffee bed

level