NKE PROCESSOR HR User manual

Zi de Kerandré – Rue Gutenberg – 56700 – HENNEBONT

http://www.nke-marine-electronics.com .

n° Audiotel 0 892 680 656 - 0,34€/min

PROCESSOR HR

Part number: 90-60-373

USER MANUAL

AND INSTALLATION GUIDE

Version V3.7

2 HR_PROCESSOR_um_EN_37

Contents

1. INTRODUCTION 4

2. THE TOPLINE NETWORK WITH PROCESSOR HR 4

3. PROCESSOR HR 4

4. SYSTEM DESCRIPTION (IMOCA TYPE) 6

5. INSTALLATION OF THE PROCESSOR HR 7

5.1 INSTALLATION OF A BRAND NEW NKE SYSTEM 7

5.2 INSTALLATION OF THE PROCESSOR REGATTA WITH AN EXISTING NKE SYSTEM 7

5.3 ADDING THE PROCESSOR HR TO YOUR NKE SYSTEM 9

5.4 ETHERNET CONFIGURATION 11

5.5 CONNECTING THE PROCESSOR HR 12

5.6 CONNECTION TO THE TOPLINE BUS 13

5.7 CONNECTOR 3D HULL AND 3D MAST 13

5.8 NMEA1/NMEA2 CONNECTORS 13

5.9 NMEA INPUT 14

5.10 NMEA SENTENCES INPUT PRIORITY RULES 16

5.11 NMEA OUTPUT 17

5.12 OPTION CONNECTOR 18

NO CABLE IS SUPPLIED BY DEFAULT. THE CONNECTOR IS A BINDER 4 CONTACTS SERIES 620

(IP67/SNAP-IN/DEXT=11.5MM). THE PIN ASSIGNMENT IS AS FOLLOWS: 18

6. CONFIGURATION OF THE PROCESSOR HR 19

6.1 ACTION OF THE LINKS 19

6.1.1 Actions 19

6.1.2 Installation and calibrations 19

6.1.3 Parameters directly settable from the Multigraphic 25

6.1.4 Analyse 26

6.1.5 Tools 27

6.1.6 Datalogs 28

6.1.7 Support 28

6.2 SOFTWARE UPDATE 29

6.3 CONFIGURE THE FILE VARIABLE.CSV 29

6.4 CHOOSING THE LANGUAGE 30

6.4.1 Patch installation procedure 30

7. ALGORITHM FOR THE PROCESSED FUNCTIONS 31

7.1 FUNCTIONS FOR BOAT MOTION 31

7.2 FUNCTIONS FOR BOAT SPEED 32

7.3 FUNCTION FOR WIND DATA 33

8. THE PILOT HR 34

8.1 ACTIVATION 34

8.2 SELECTING THE HR AUTOPILOT ON THE MULTIGRAPHIC 34

8.3 SELECTION OF PILOT HR WITH THE GYROGRAPHIC 35

9. CALIBRATING YOUR SYSTEM 36

9.1 INTRODUCTION 36

3 HR_PROCESSOR_um_EN_37

9.2 CALIBRATION ORDER 36

9.3 CALIBRATING THE COMPASS 37

9.4 ROLL AND PITCH CALIBRATION 37

9.5 CALIBRATING BOAT SPEED 37

9.5.1 Linear boat speed response against boat’s heel angle 38

9.6 CALIBRATING FOR DRIFT 39

9.6.1 Using a drift calibration adjustment value: 40

9.7 CALIBRATING TRUE WIND SPEED 40

9.8 APPARENT WIND ANGLE 42

9.9 CALIBRATING TRUE WIND ANGLE 43

10. PERFORMANCE AND POLAR TABLES 46

10.1 READING A POLAR TABLE 47

10.2 READING A POLAR DIAGRAM 48

10.3 PERFORMANCE FUNCTIONS 49

11. ADDENDUM A 52

11.1 CONFIGURING THE PC FOR THE FIRST CONNECTION TO THE PROCESSOR HR 52

11.1.1 Connecting the Processor HR to the PC 52

11.1.2 Configuring the network connection with Windows XP 52

11.1.3 Configuring the network connection with Windows Seven 53

11.1.4 Testing the connection with the Processor HR 57

12. FREQUENTLY ASKED QUESTIONS 58

4 HR_PROCESSOR_um_EN_37

1. INTRODUCTION

Thank you for choosing nke and the PROCESSOR HR. You have purchased a processor

that sits at the heart of a system which provides the autopilot, the navigation programme,

the tactician, the crew and of course the skipper all the data they require. The data

provided is optimised for accuracy, responsiveness and performance.

In this manual you will find all the information necessary to:

- Carry out Installation, configuration and calibration of the Processor HR and sensors

- Access all the functions offered by the Processor HR

- Get the best performance from your boat.

2. THE TOPLINE NETWORK WITH PROCESSOR HR

The Topline system consists of sensors and displays networked with a single 3 wire cable

(shield: 0V, white: +12V, black: Data). Data is carried on the black “DATA” wire.

Displays have a variable address ranging from 1 to 20 while the sensors have a fixed

address with a value comprised between 21 and 210. The network is managed from one

of the displays that will be chosen as “MASTER” during the system commissioning. Its

address will be “1”.

Once turned on, the “MASTER” will scan all the addresses to discover all the displays and

sensors which are connected to the network.

Once the “MASTER” has scanned the network, it will ping only the channels it has

identified. Also, the “MASTER” will randomly ping the channel “0” (non identified display).

A specific answer from a display will generate an address for that display to integrate

dynamically with the network.

3. PROCESSOR HR

The Processor HR provides the following:

1. Performance:

Accurate measurement of wind speed and angle (true and apparent), boat speed,

speed over ground, the boat movements, all with sensitivity to small changes.

Accurate measurement of acceleration and the boat’s attitude (magnetic heading,

angles, acceleration, turn rates, magnetometric vector)

Accurate dynamic calculation of true wind as a result of the compensation of

measured data from the masthead sensor, the geometry between the mast and the

hull and the use of corrections table.

5 HR_PROCESSOR_um_EN_37

2. Fast data provision:

High speed data flow (fast reactivity to the measurements from sensors providing

high speed updates to the autopilot and data display).

Fast data rate interface with the on-board PCs for the major navigation packages

(via the SailNet protocol on IP and various gateways). Compatible with the Proteus

communication system.

3. Safe and secure operation:

Integrated safety: various safe modes allow use of the main functions without the

Processor Regatta.

The use of the lightest possible Linux OS ensures real time operation without

background task (or virus) and avoiding mechanical moving parts (such as hard

disk, fans…)

Auto diagnostic log for a good understanding in case of malfunction.

4. Standardisation :

Simple and open formats and protocols specified for:

Variables logs

Variable exchange protocol via fast RS232/NMEA0183 or IP.

Adjustment for the linear calibrations, filtering, alarms and non-linear calibration

files, polar tables.

Use of one single variable definition base for each level: in the remote Gyropilot

Graphic display, the Processor HR, the variables log, the compatible navigation

software (Deckman), the IP broadcast, the post-processing software (Excel..), the

diagnostic software (Toplink ...).

5. Post-processing:

Internal communication for diagnostics and modelling.

6. Open data:

Functions can be customized or translated (display on the Gyropilot Graphic,

Deckman, Tools).

Open IP protocol for « SailNet » variables exchange (Linux/windows libraries with

samples supplied, possibility to use several boats and/or navigation programs

simultaneously).

7. Upgrades:

Easy Processor HR update via IP

Use of the Topline peripherals with a Flash memory for onboard update with PC

Toplink.

Processor HR interface page on the Gyropilot Graphic display for easy HCI update.

8. Power management:

Allows the on board PC to operate in standby mode while getting the performance

data on the nke displays.

The Processor HR enhances the wind data (faster refresh and less noise). As a

consequence, the autopilot steering is optimized and reduces the use of the ram’s

motor.

6 HR_PROCESSOR_um_EN_37

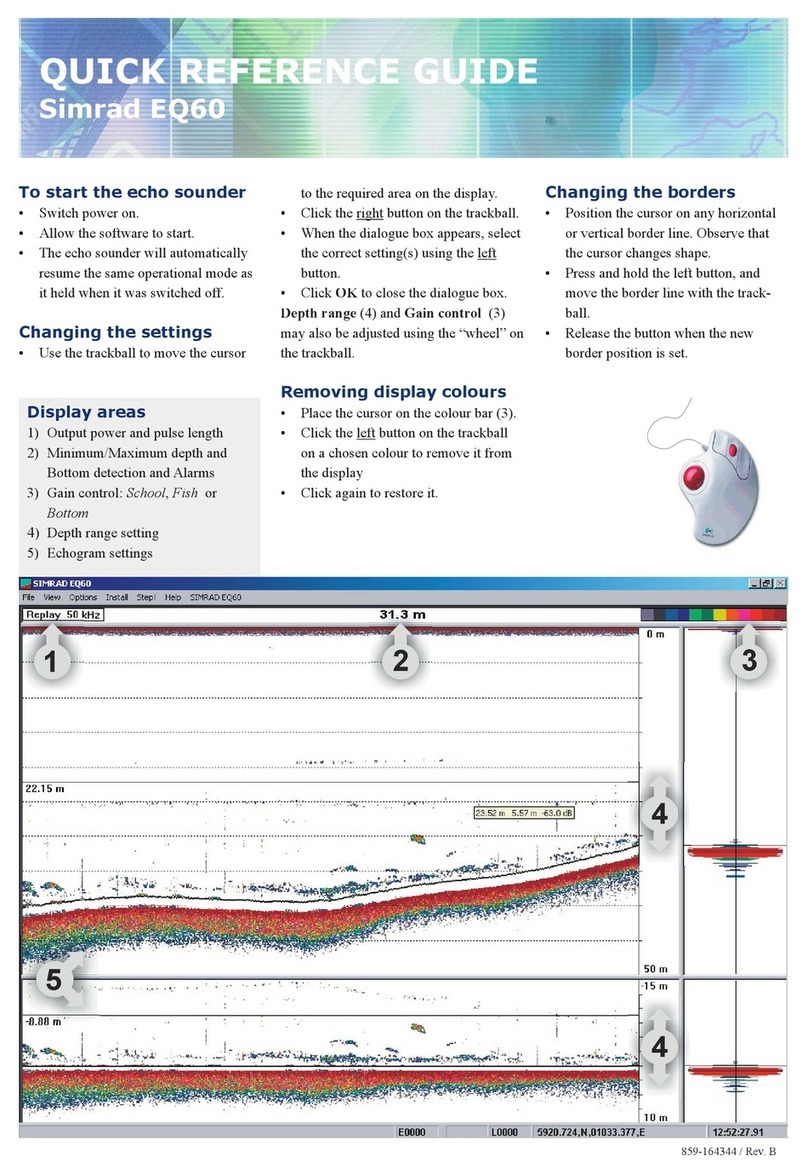

4. SYSTEM DESCRIPTION (IMOCA TYPE)

The equipment featured in this drawing is for indication only.

It does not reflect your own system.

7 HR_PROCESSOR_um_EN_37

5. INSTALLATION OF THE PROCESSOR HR

In this chapter we will cover the installation of the unit and all calibration required in the

Topline network environment.

5.1 Installation of a brand new nke system

All units except the Processor Regatta must be installed first. Please refer to the manual

for each unit (sensors, displays…). We recommend using the Mutltigraphic or

Gyrographic as the system’s Master.

Once the system is installed, refer to “How to integrate Processor Regatta in an existing

nke system” to complete the installation.

5.2 Installation of the Processor Regatta with an existing nke system

As a first step, you need to update every component connected to the Topline network.

This is done with the « Toplink2 » software, or alternatively you can send the units to nke

customer support.

Firmware, database and the Toplink2 software (requires the Topline USB interface 90-60-

482) are all available for download at the following address: http://www.nke-marine-

electronics.com in the technical area (requires a password – access to trade only).

WARNING

- Please take time to read this manual carefully before you start installation.

- Any connection to the TOPLINE bus must be performed through the specific interface

box: 90-60-417.

- Any work on the TOPLINE bus requires the system to be powered off.

8 HR_PROCESSOR_um_EN_37

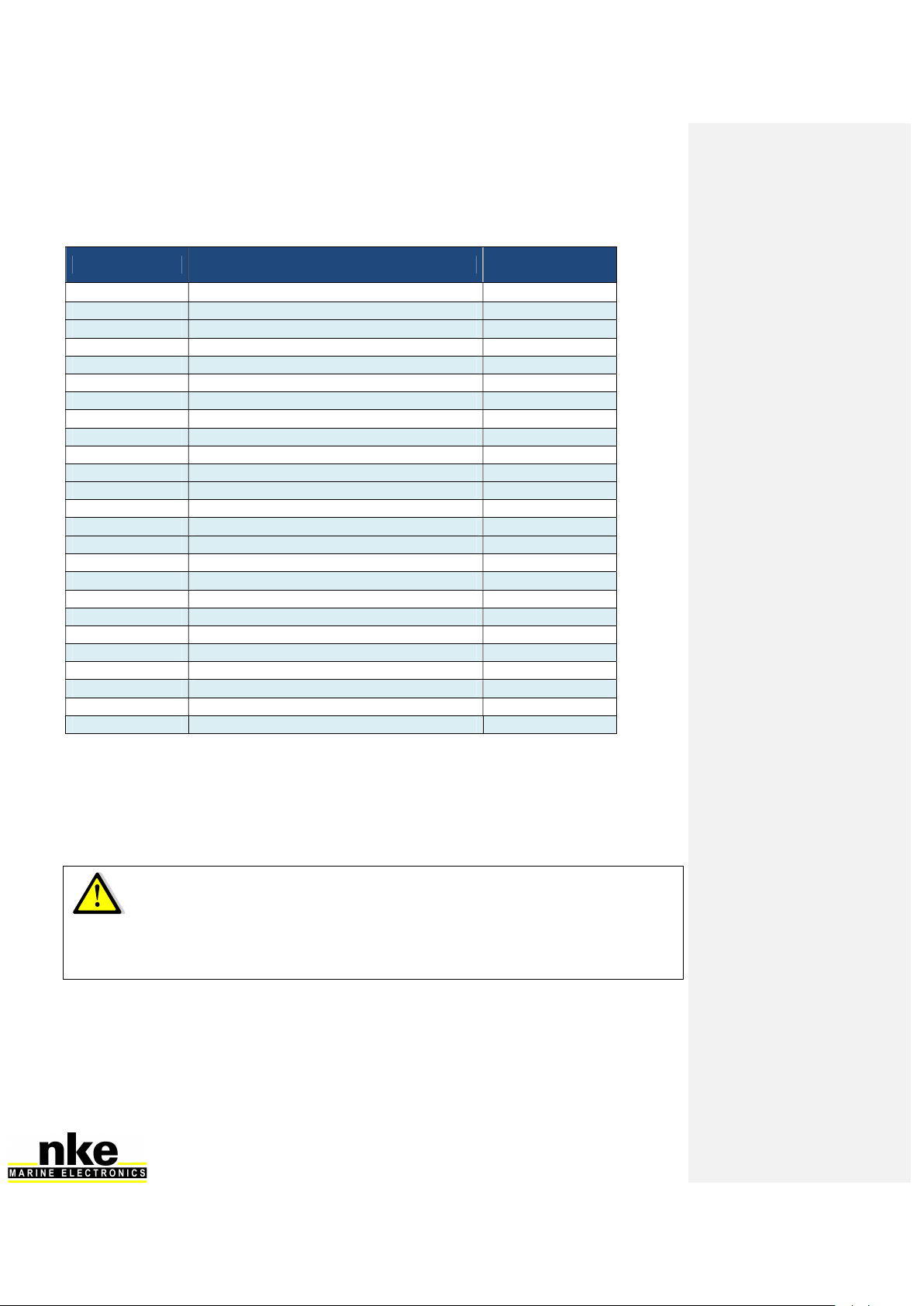

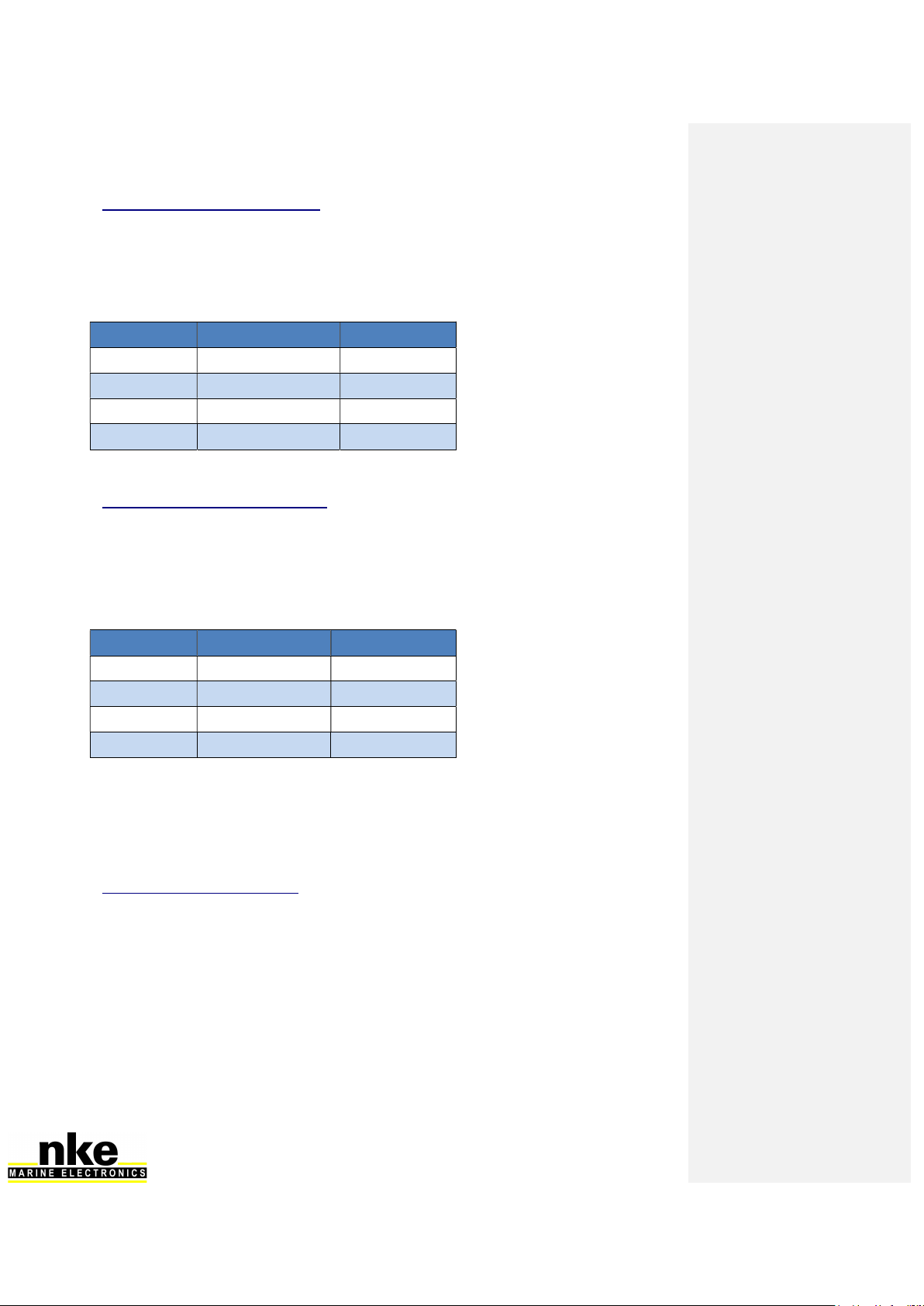

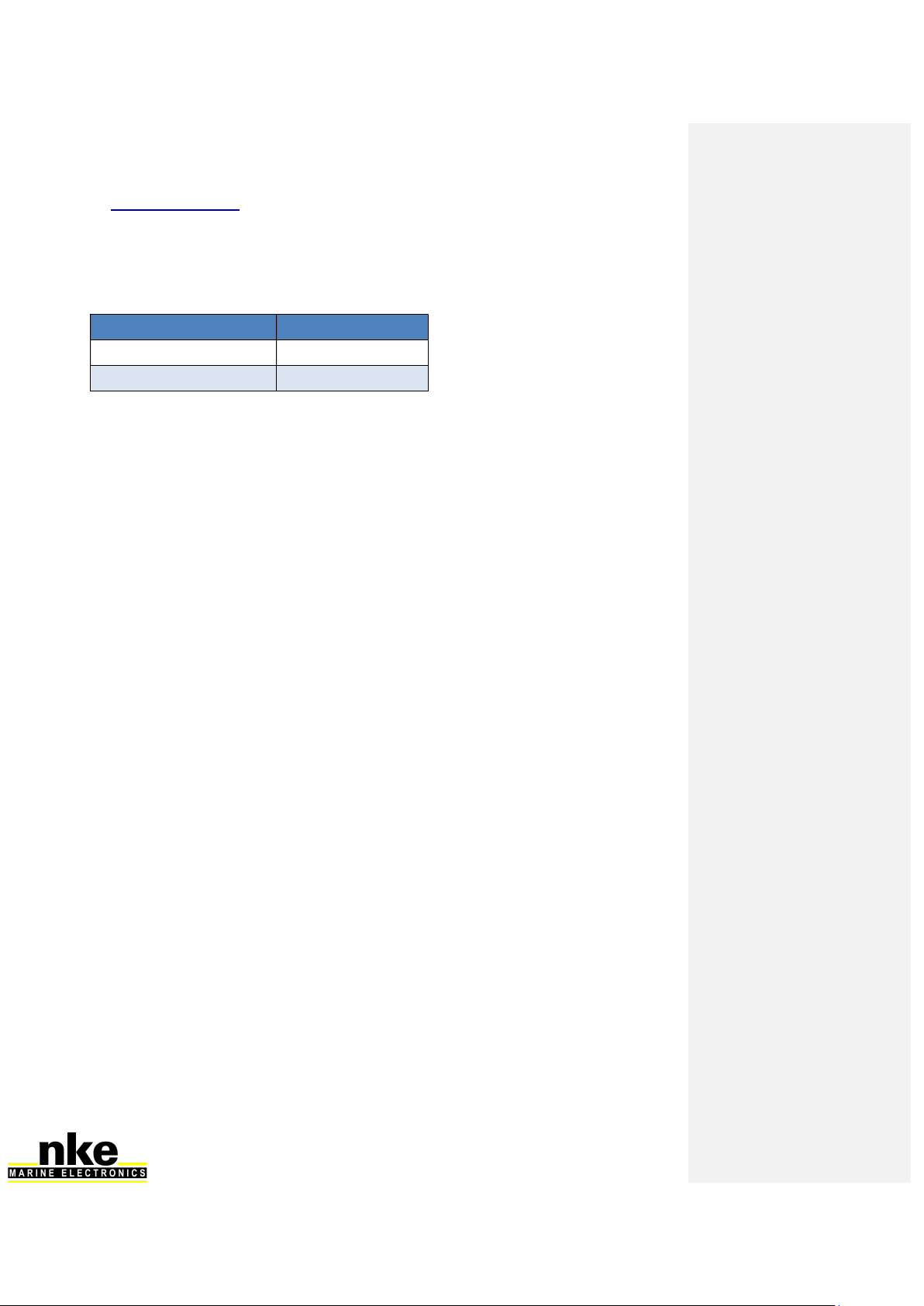

Table of versions compatibility with the Processor HR:

Module type Description Minimum Version

required

Display Performance Limited use

Display Multigraphic All versions

Display Gyropilot Graphic V3.1

Display SL50 V1.4

Display TL25 V1.5

Interface Remote control (wired) V2.1

Interface Radio receiver V2.4

Interface NMEA output interface

Interface NMEA input interface V1.2

Interface Toplink 2 N.A.

Interface WiFi box All versions

Sensor Single battery pack control Not compatible

Sensor Dual battery pack control Not compatible

Sensor Battery Monitor 500 All versions

Sensor 3D Sensor N.A.

Sensor Mast angle sensor V1.4

Sensor HR 100 barometric sensor V1.0

Sensor Ultrasonic starboard / port V1.6

Interface Speed and depth Interface V2.0

Interface Dual-speed and depth Interface V2.0

Sensor Carbowind HR V1.8

Sensor AG HR V1.8

Sensor Regatta Compass Interface V1.4

Sensor Fluxgate compass V1.7

Autopilot Pilot processor V2.8

Once you have ensured that all units are up to date with a compatible version, you can

power the system on and check that it works properly. We strongly recommend choosing a

Multigraphic or Gyropilot Graphic display as Master of the Topline network. This will

make the integration of the Processor Regatta easier to manage.

WARNING

If the instruments connected to the bus are not up to date with the latest firmware version,

the PROCESSOR HR cannot work and an error message is displayed in the "Main

Events" log to indicate the out of date instrument.

9 HR_PROCESSOR_um_EN_37

+

+

5.3 Adding the Processor HR to your nke system

When all the sensors, displays and interface units have been upgradedcompatible with the

Processor HR and fully working, you are ready to add the Processor HR to the network.

Once in place, it will become the Master. Therefore, the existing Master has to be deleted

so that the Topline network is clean of any Master.

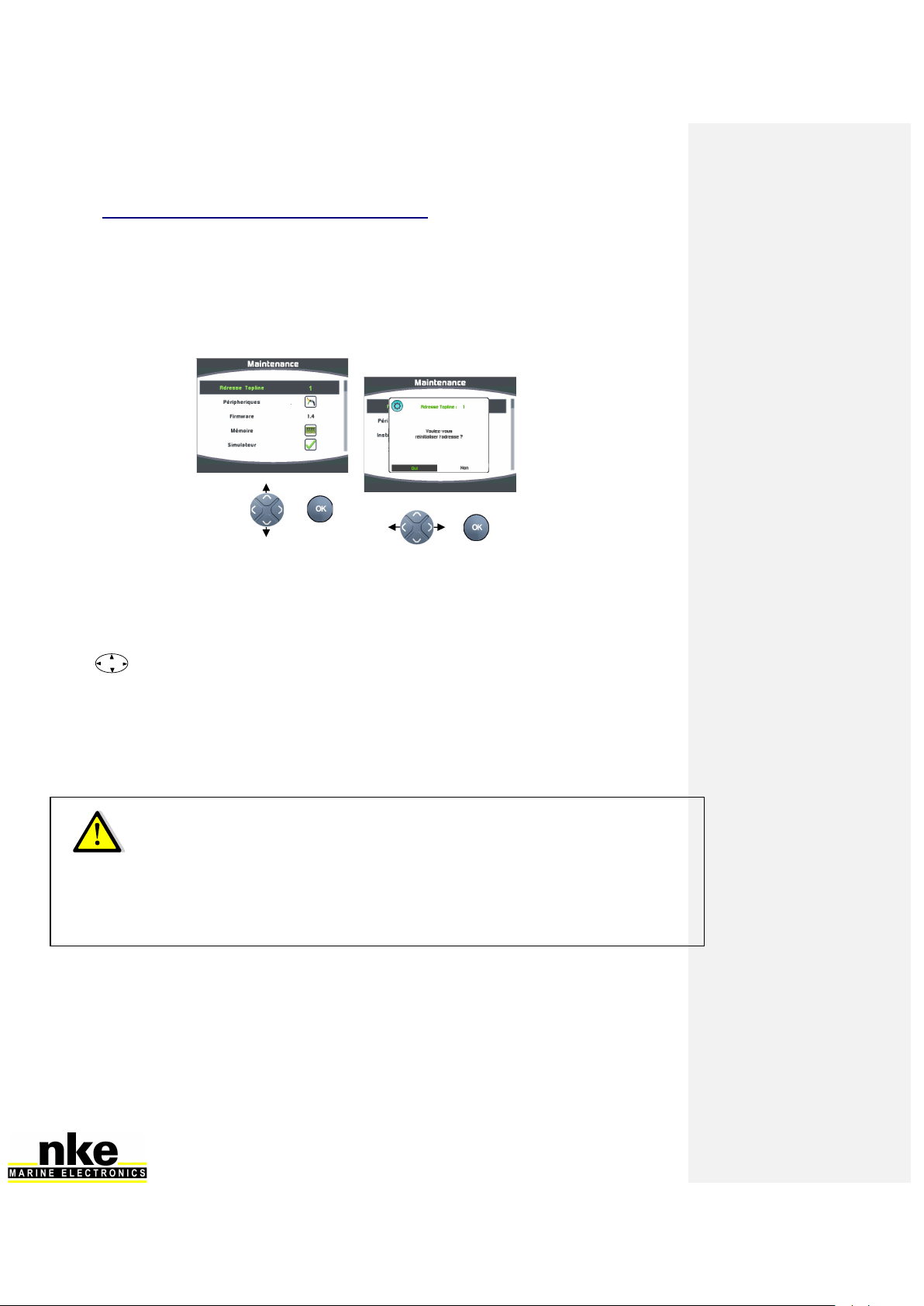

- If the Multigraphic (current Master) must be given a new node:

- If the Gyropilot Graphic (current Master) must be given a new node:

Display the Main Menu (Menu: main) with the Page key of the Gyropilot

Graphic

Choose Configuration and then Initialisation adress with the navigation pad

11

Accept with Ent,

You will get the following message « To set the address to 0 press Ent»,

accept again by pressing Ent,

the following message will display «Gyropilot address 0»

The 3D sensor must be connected to the « 3D HULL » connector before connecting the

PROCESSOR HR (refer to the unit’s manual). The PROCESSOR HR will automatically

detect those sensors (version 2.4 and up).

When powering the Topline network on, a blue LED situated on the front face of the

PROCESSOR HR indicates the working status. The PROCESSOR HR always acts as the

Master. When the system is powered on, the Master will create 2 « Lists ». Allow 30

seconds for boot completion.

WARNING

10 HR_PROCESSOR_um_EN_37

+

+

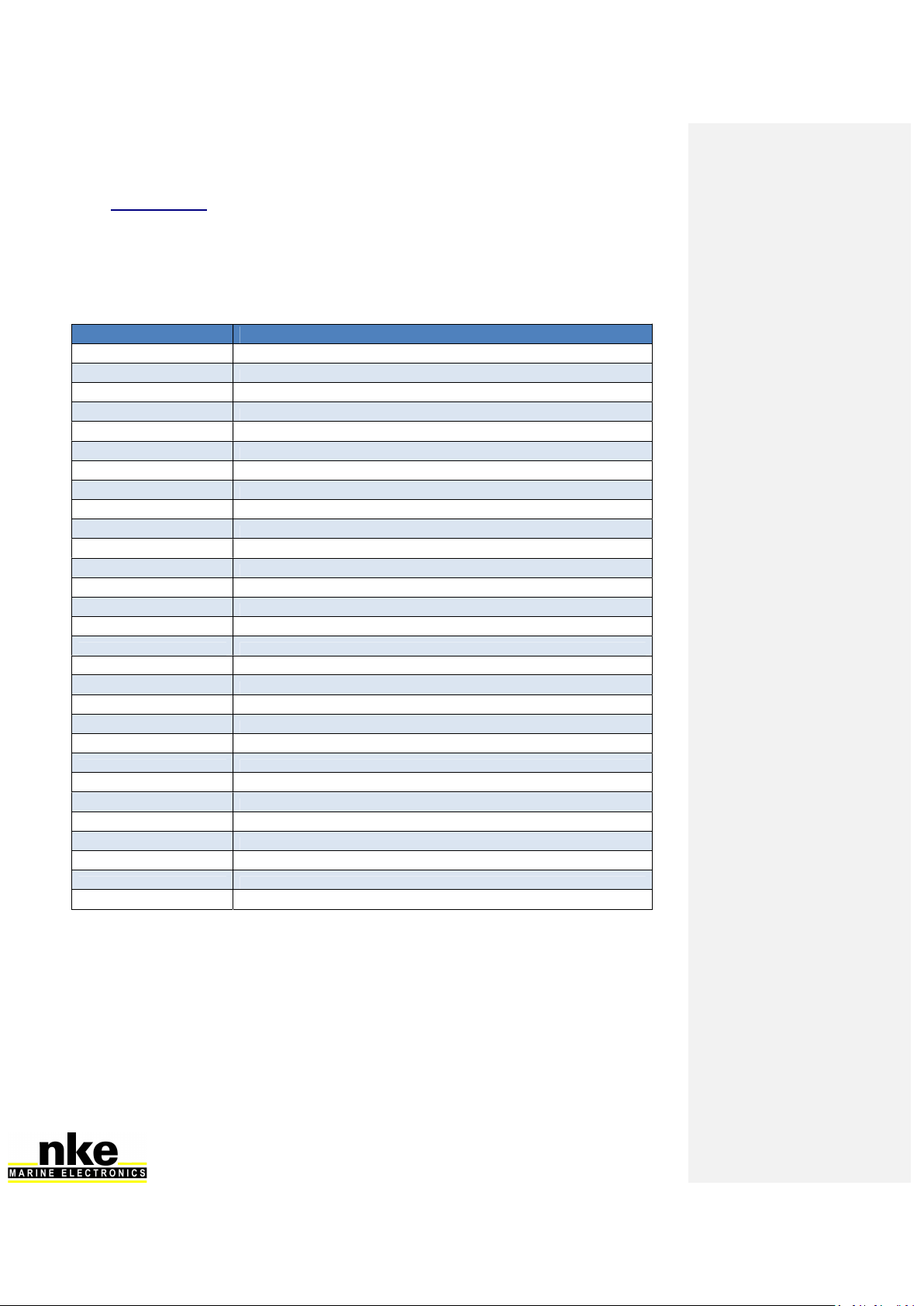

LED status Working status or fault description

LED off - Processor is powered off or faulty.

Blue Led

1 blip every 3

seconds

▲ 3s ▲

- Processor HR in normal working status

- internal auto-check is correct

100ms blip rate

▲ ▲ ▲ ▲ ▲ ▲ ▲

- Processor HR is booting

1 blip per second

▲ ▲ ▲ ▲

-

The Processor has detected a serious error (lost a sensor,

firmware version is not compatible...

Fixed light - Processor is out of work or booting.

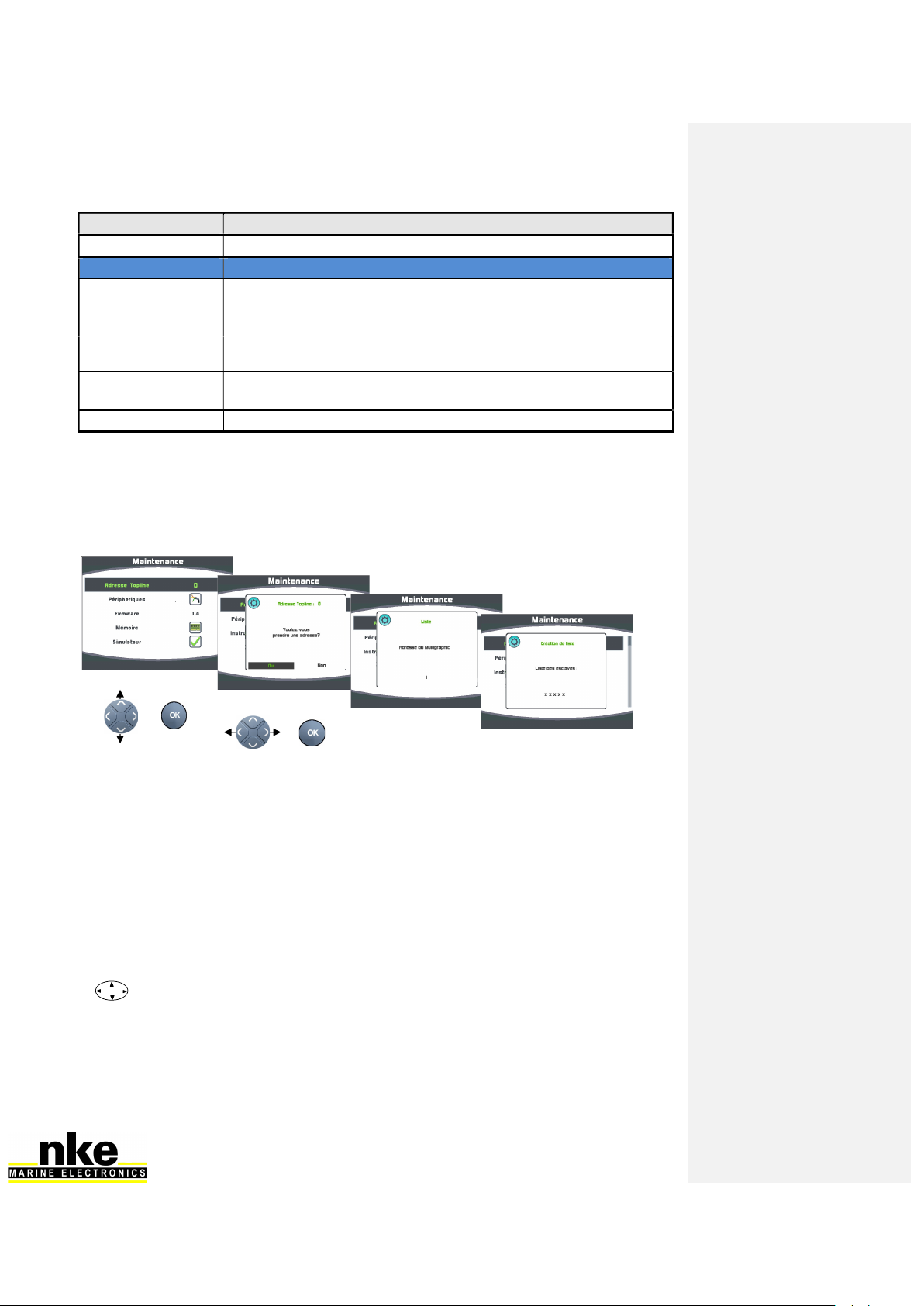

Once the PROCESSOR HR has started (Blue LED blips every 3 seconds), you can give a

new node number to the Gyropilot Graphic which has been used previously to check the

system. Use the following procedure:

For the Multigraphic:

Gyropilot Graphic:

the message « set an address in the Gyropilot in Menu/Configuration » is

displayed on the Gyropilot Graphic. It has not been initialized.

The system boot must be fully completed before any node can request an

address to the Processor. Once the data is displayed on the TL25, allow another 10

seconds.

Display the Main Menu (Menu principal) with the Page key of the Gyropilot

Graphic

Choose Configuration and then Initialisation adresse with the navigation pad

11

Accept with Ent,

The following message is displayed « to get an address press ENT», press

Ent,

11 HR_PROCESSOR_um_EN_37

The following message is displayed « liste» and the Gyropilot gets a node

number which will be temporarily displayed.

Press Page to exit.

The List creation is a long process (30 seconds). Always wait until the PROCESSOR HR

boot is completed (blue LED = 1 blip every 3 seconds) before asking for a new node

number.

5.4 Ethernet configuration

Depending on the network configuration on board your boat, several connection options

are possible between your Processor HR and the PC.

Direct Ethernet connection:

The network cable is supplied with the Processor HR. It is a crossover cable that allows

direct connection to your PC.

Ethernet connection via a network:

The cable supplied with your Processor HR is a crossover cable. It allows connection with

the most recent Ethernet Switches. Please check your Ethernet Switch compatibility with

crossover cables. If not, you should use a straight-through cable.

RJ45 crossover network cable

WARNING

12 HR_PROCESSOR_um_EN_37

5.5 Connecting the Processor HR

Prior to connection, you must have configured your PC. The connection will operate via

ftp, http, and the Sailnet dll and will allow access to the calibrations tables, the log files

for trouble-shooting and software updating.

The default address of the Processor HR is 192.168.0.232 and the connection credential

is:

Login name: root

Password: pass

Please check the following points before any connection:

The blue LED indicates that the Processor HR works properly

On the Ethernet RJ45 on: yellow LED indicates activity / green LED indicates

physical connection

Firewall: allow all ports for 192.168.0.232

If you use a Proxy: in the advanced connection settings of your web browser, add

"192.168.0.232" in the section "not use Proxy for the addresses".

The HR processor does not manage DHCP server. If you use a point to point

Ethernet and don’t have an IP address automatically attributed by DHCP, you

should give your PC a fixed IP address such as 192.168.0.X where X is different

from 232, which is the default address of the Processor HR. (see addendum A -

Connecting the Pocessor HR)

With the http protocol:

Open your Internet browser (Internet explorer, Firefox etc.) and type in the address

http://192.168.0.232 in the address bar and press « Enter » or click on the connection

button to accept.

The Processor HR configuration page will appear.

With the FTP protocol:

To connect to the FTP server from your PC without having a user name and a password,

type in an Explorer window the address:

ftp://root:[email protected]

You can access to the internal USB key by typing:

ftp://root:[email protected]/var/usbdisk/

Access to the configuration files for Processor HR is available at:

ftp://root:[email protected]/mnt/flash/processor/

With Telnet protocol:

In the command prompt of the Start menu, type telnet 192.168.0.232 and press “Enter”. A

« dos » window will open. For security reasons a credential will be asked to be filled in.

Login name: root

Password: pass

Alternatively, you can use the login name: p which does not require a password.

If you have difficulties connecting to the Processor HR, refer to the paragraph

"Configuration of my computer for the first connection to the Processor HR "

13 HR_PROCESSOR_um_EN_37

5.6 Connection to the Topline bus

The Processor HR features a Topline plug for connection to the Topline bus which carries

the 12 volts power supply as well.

Cable: twisted pair with aeronautical type shield.

Connector:

Wire Colour

Termination

Blue Topline Data 3 and 5 together

White +12V 4

Shield Common 1

Not connected +5V OUT 2

5.7 Connector 3D Hull and 3D Mast

The 3D Sensor is connecting to the 3D Hull connector.

Cable: 3 wires + aeronautical type shield

Connector: Binder 5 contacts series 620

Cable: 90-60-392 (5 Meters)

Wires Colour

Function

T

ermination

Blue TX Processor 5

White RX Processor 3

Shield Common 1

Orange +12V OUT 4

The 3D Mast is not used.

Please note: Compass Regatta can be powered and communicate with this connector

which can also receive data from the 3D Sensor.

5.8 NMEA1/NMEA2 connectors

These connectors can power and receive data from an NMEA device up to 115kb. Refer to

6. Configuration of the Processor HR for the port configuration.

NMEA1 is an IN/OUT port and NMEA2 is just INPUT port.

Cable: 3 wires + aeronautical type shield

Connector: Binder 5 contacts series 620

Cable: 90-60-522

14 HR_PROCESSOR_um_EN_37

Wire colour

Function

Termination

Termination DB9

Blue TX Processor = RX NMEA

5 2

White RX Processor = TX NMEA

3 3

Shield Common 1 5

Orange +12V OUT 4 Isolate

5.9 NMEA input

Below is the list of NMEA sentences accepted by the Processor HR

Each NMEA sentence matches with channels on the Topline bus

Channels are automatically detected. NMEA channels created by the Multigraphic or

Gyropilot Graphic remain as priority input on the NMEA port of the Processor HR

NMEA Code Function

number Possible Functions associated

APB

64 XTE (Cross Track Error)

70 Autopilot status

71 Bearing Origin Waypoint to Destination Waypoint

BOD 71 Bearing Origin Waypoint to Destination Waypoint

BWC 62 Distance to waypoint

63 Bearing to waypoint

BWR 62 Distance to waypoint

63 Bearing to waypoint

CUR 76 Drift (current)

77 Set (current)

DBT 22 Depth

DPT 22 Depth

GGA

86 Latitude Degrees and Minutes

87 Latitude Minutes decimals

88 Longitude Degrees and Minutes

89 Longitude Minutes decimals

GLL

86 Latitude Degrees and Minutes

87 Latitude Minutes decimals

88 Longitude Degrees and Minutes

89

Longitude Minutes decimals

GNS

86 Latitude Degrees and Minutes

87 Latitude Minutes decimals

88 Longitude Degrees and Minutes

89 Longitude Minutes decimals

HDG True Heading - geographical North

198

Magnetic Heading

–

Safe Mode

KVH

198 Magnetic Heading – Safe Mode

199 Heel Angle – Safe Mode

200 Trim Angle – Safe Mode

MDA 48 Air Temperature

15 HR_PROCESSOR_um_EN_37

49 Water Temperature

119 Barometric pressure – High resolution

MMB 119 Barometric pressure – High resolution

MTA 48 Air Temperature

MTW 49 Water Temperature

MWV 192 Apparent Wind Speed – High resolution

193 Apparent Wind Angle – High resolution

RMB

62 Distance to Waypoint

63 Bearing to Waypoint

64 XTE (Cross Track Error)

67 VMG to Waypoint

RMC

27 UTC minutes and seconds

47 UTC Hour and Day

69 UTC Year and Month

86 Latitude Degrees and Minutes

87 Latitude Minutes decimals

88 Longitude Degrees and Minutes

89 Longitude Minutes decimals

208 Speed Over Ground

209 Course Over Ground

ROT 207 Rate of turn and direction of turn.

VBW

21 Boat Speed

42 Dead reckoned drift angle

208 Speed Over Ground

209 Course Over Ground

VDR 76 Drift (current)

77 Set (current)

VHW 21 Boat Speed

118 True Heading - geographical North

VLW 32 Log

31 Trip Log

VTG 208 Speed Over Ground

209 Course Over Ground

VWR 192 Apparent Wind Speed – High resolution

193

Apparent Wind Angle

–

High res

olution

WCV 67 VMG to Waypoint

XTE 64 XTE (Cross Track Error)

70 Autopilot status

XTR 64 XTE (Cross Track Error)

ZDA

27 UTC minutes and seconds

47

UTC Hour and Day

69 UTC Year and Month

ZDL_R 62 Distance to Waypoint

222 Time to Waypoint

ZDL_T 225 Distance to Layline

226 Time to Layline

16 HR_PROCESSOR_um_EN_37

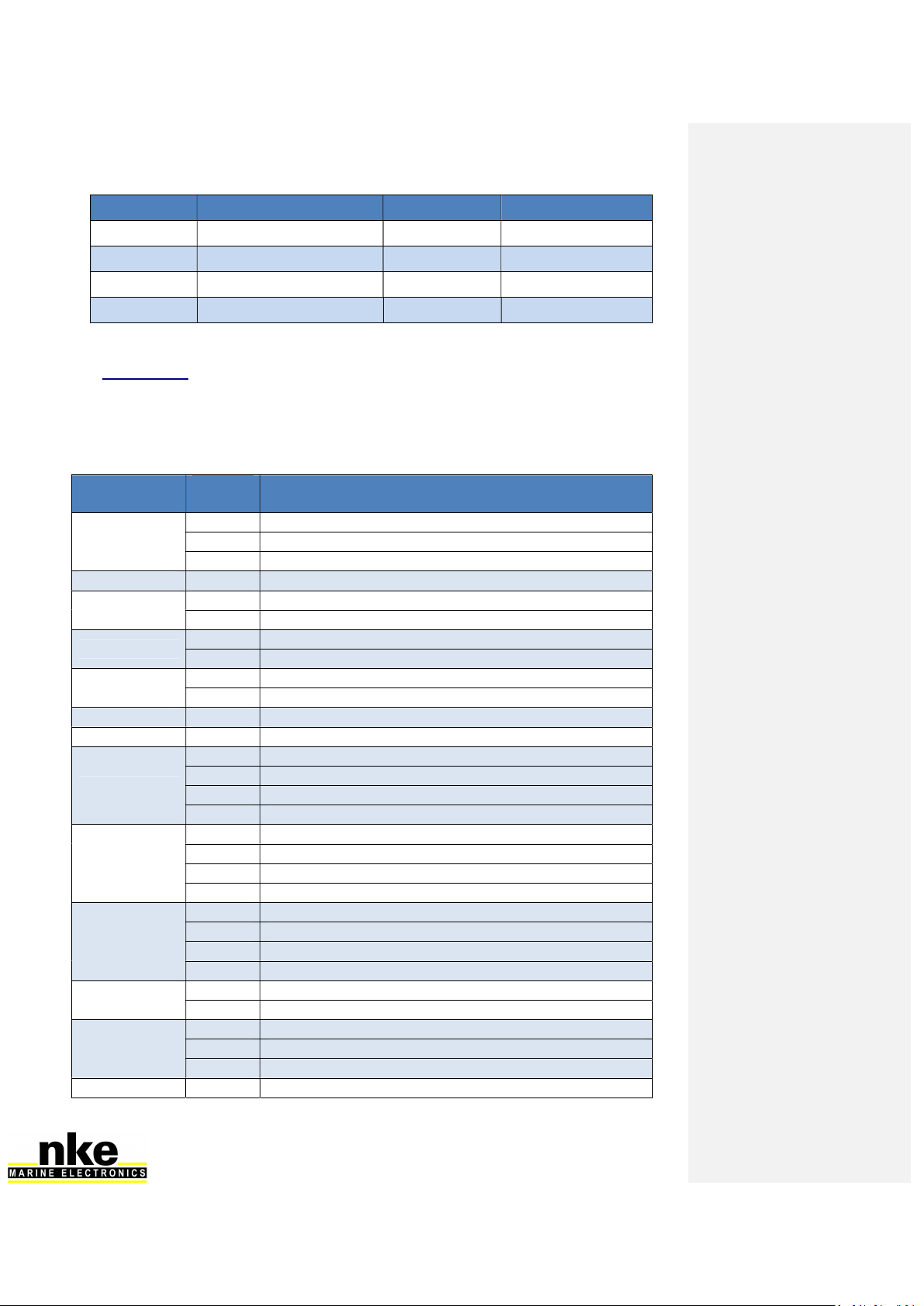

5.10 NMEA sentences input priority rules

A priority order is given to the data coming from the Topline bus on NMEA data.

NMEA sentences from the displays have a priority order on those coming from the

processor.

Each Function can be fed by several NMEA sentences. The table below indicates priority

between NMEA sentences.

Nu

m Variable High Medium High

Mediu

m Low Low

21

Boat Speed VBW VHW

22

Depth DPT DBT

27

UTC minutes and seconds ZDA RMC

32

Log VLW

31

Trip Log VLW

47

UTC Hour and Day ZDA, RMC

48

Air Temperature MTA MDA

49

Water Temperature MTW MDA

62

Distance to Waypoint BWC RMB BWR ZDL_R

63

Bearing to Waypoint BWC RMB BWR

64

XTE (Cross Track Error) RMB APB XTE XTR

67

VMG to Waypoint WCV RMB

69

UTC Year and Month ZDA RMC

70

Autopilot status APB XTE

71

Bearing Origin Waypoint to

Destination Waypoint APB BOD

76

Drift (current) VDR

77

Set (current) VDR

86

Latitude Degrees and Minutes GNS GGA RMC GLL

87

Latitude Minutes decimals GNS GGA RMC GLL

88

Longitude Degrees and Minutes GNS GGA RMC GLL

89

Longitude Minutes decimals GNS GGA RMC GLL

True Heading - geographical North

119

Barometric pressure – High resolution MMB MDA

192

Apparent Wind Speed – High

resolution MWV VWR

193

Apparent Wind Angle – High

resolution MWV VWR

198

Magnetic Heading – Safe Mode KVH HDG

199

Heel Angle – Safe Mode KVH

200

Trim Angle – Safe Mode KVH

207

Rate of turn and direction of turn

ROT

208

Speed Over Ground VBW RMC VTG

209

Course Over Ground VBW RMC VTG

225

Distance to Layline ZDL_T

226

Time to Layline ZDL_T

222

Time to Waypoint ZDL_R

17 HR_PROCESSOR_um_EN_37

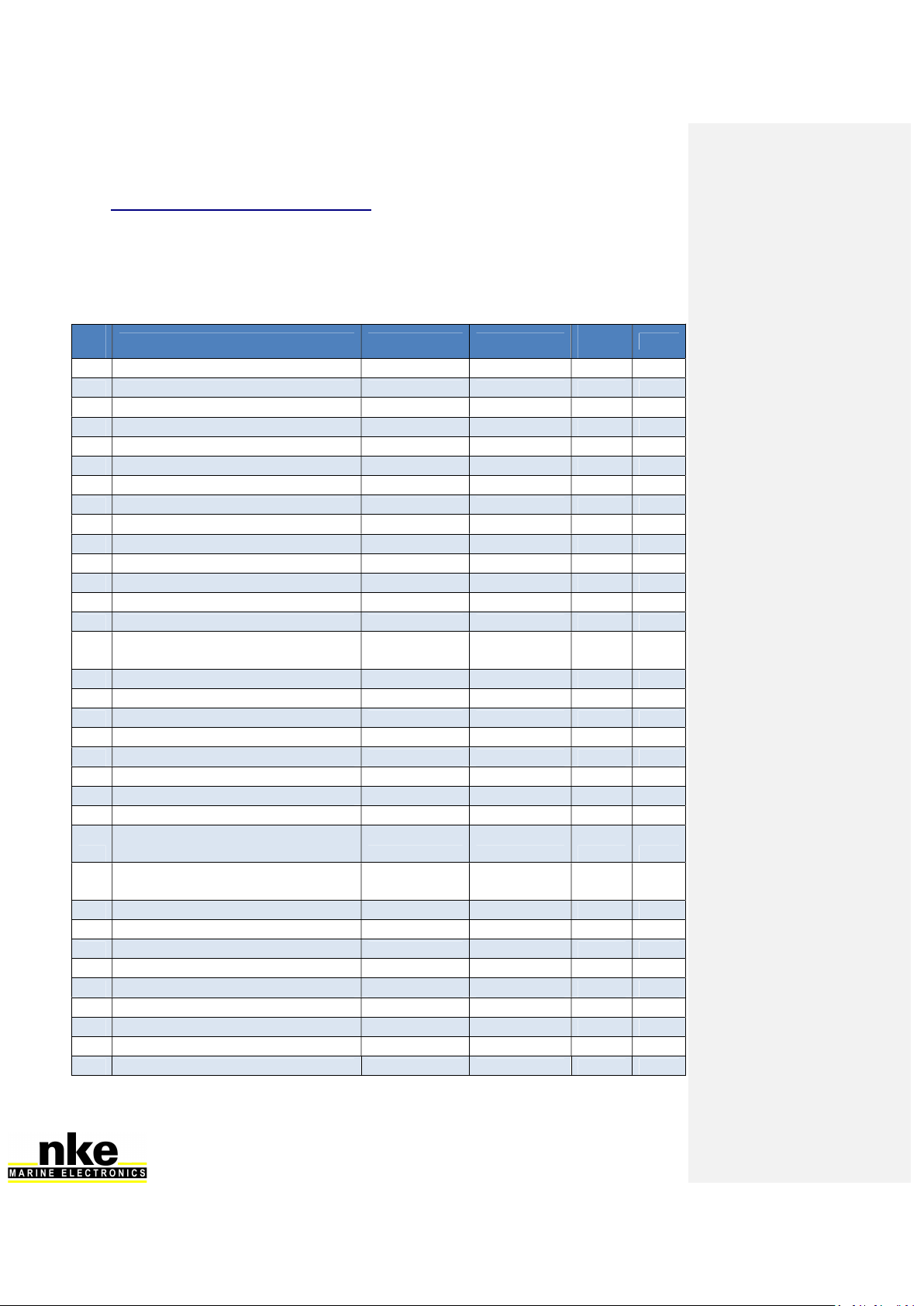

5.11 NMEA output

Output frequency is linked to the baud rate selected.

The table below shows all NMEA sentences that can be output from the processor. An

NMEA sentence will be available for output if at least one value contained in the sentence

is used by the processor.

NMEA sentence Description

$INDBT … Depth below keel

$INDPT … Depth below keel

$INGGA … Global Positioning System Fix Data

$INGLL … Geographic position

$INHDG … Heading – Deviation and Variation

$INHDT … True Heading

$INMTW … Sea Temp

$INMWV,x.x,R … Apparent Wind Angle and Speed

$INMWV,x.x,T … True Wind Angle and Speed

$INMWD …

True Wind Direction and Speed

$INRMB … Recommended Minimum Navigation

$INRMC … Recommended Minimum GNSS Data

$INRSA … Rudder angle

$INVDR … Set and Drift

$INVHW … Water Speed and Heading

$INVLW … Dual Ground/Water Distance

$INVPW … VMG

$INVTG … Course/Speed Over Ground

$INWCV … Waypoint closure velocity

$INXDR …,C,x.x,C,AIRT … Air Temperature

$INXDR …,P,x.x,B,BARO … Barometer

$INXDR …,N,x.x,N,FRST … Forestay

$INXDR …,A,x.x,D,ROLL … Heel angle

$INIXDR ...,H,x.x,P,HYGR … Humidity

$INXDR …,A,x.x,D,KEEL … Keel Angle

$INXDR …,A,x.x,D,LEEW … Leeway angle

$INXDR …,A,x.x,D,MAST … Mast angle

$INXTE … Cross Track Error, measured

$INZDA … UTC Time and Date

18 HR_PROCESSOR_um_EN_37

5.12 Option Connector

No cable is supplied by default. The connector is a Binder 4 contacts series 620

(IP67/snap-in/Dext=11.5mm).

The pin assignment is as follows:

Function

Termination

+12V OUT 1

ACS OUT 3

Pins 1 & 3 + 12V OUT and OUT allow ACS command a

solenoid ( electromagnet, power relays ... ). By default, this output is

dedicated to anti- capsize or keel release system.

Please note: ACS OUT output is open drain type and is limited to 2A / 16V on

a few seconds.

19 HR_PROCESSOR_um_EN_37

6. CONFIGURATION OF THE PROCESSOR HR

In this chapter we will cover the configuration of the Processor HR for your electronics

and information system.

You can access the Processor Regatta home page by typing this address in your Internet

browser: http://192.168.0.232 (refer to addendum A for Computer configuration).

In this page you can find several links to the calibration tools.

6.1 Action of the links

6.1.1 Actions

Reboot processor: Restart the Processor HR

Stop processor: Stop the PROCESSOR HR

Save a backup on the USB stick: Backup all calibrations and tables in USB stick.

Refresh calibrations from the USB stick and restart: Load all backup calibration

parameters and tables from the USB stick and restart the PROCESSOR HR.

6.1.2 Installation and calibrations

Calibrating the constants

The access to the file "Cali.ini" is on the following path:

ftp://root:[email protected]/mnt/flash/processor/constants

Some constants, not accessible from a Display, can be adjusted here. It contains two

sections.

20 HR_PROCESSOR_um_EN_37

[Dampings]

USspdDampLost = 15 ; Filtering speedometer's losses US (seconds)

MastAngDamp = 3 ; Filtering mast angles (table 0..31)

[Constants]

HdgOff = 0.0 ; Additional heading offset (degrees)

MastRotOff = 0.0 ; Mast twist offset (degrees)

MastDeflOff = 0.0 ; Mast tilt/deflection (degrees)

WindShear = 0.0 ; Windshear (degrees)

AWSOff = 0.0 ; Apparent Wind Speed offset (knots)

FailSafeBS = 6.0 ; Spare Boat Speed (knots)

MeasLeewayOff = 0.0 ; Drift sensor offset (degrees)

[MotionWindComp]

WindVaneHigh = 30.0 ; Aerial sensor's height / Rotation centre with heel

(metres)

Coef1 = 6 ; (3DHV2 = 6) (KVH = 4)

Coef2 = 3 ; (3DHV2 = 3) (KVH = 2)

[Anticapsize]

HeelAcsLimit = 35.0 ; Heel angle limit to

prevent capsize (degrees, 0=no)

TrimAcsLimit = 35.0 ; Pitch angle limit to prevent capsize (degrees,

0=no)

AccXAcsLimit = -15 ; m/(s*s).0=no)

AcsConfTime = 0 ; Confirmation time-laps ACS (ms)

AcsCmdTime = 500 ; Command time ACS output (ms)

[PilotHR]

TackingSpeed = 20 ; Rate of turn when tacking /s)

GibingSpeed = 10 ; Turn rate when gybing /s)

SecPerBoomTp = 1 ; Gybing: number of seconds per timeout unit for boom

shift (s)

GibingBoomOff = 0 ; Gybing: Angle offset when the boom shifts over

(degrees)

TackOffset = 5 ; Offset value to catch up speed after tacking

(degrees) -1=disabled

WARNING

The default configuration of this file is correct for 60’ Open but you can apply

modifications should you want to customize your system.

Modifications are saved by pressing « Save File » and will be applied after you reboot

the Processor HR. This is done by pressing « Reboot Processor».

The "Coef" value is entered according to the

sensor connected to the 3Dhull.

This manual suits for next models

1

Table of contents

Other NKE Marine Equipment manuals