Installation and Troubleshooting Guide

This installation is to be completed by an Authorized Dealer or Professional Service

Technician. For questions regarding installation or warranty, call CDI Tech Support

at 866-423-4832. Do not return to the Dealer or Distributor where the part was purchased.

Contact CDI Electronics Directly for Return Material Authorization.

CDI Electronics, LLC •353 James Record Road SW •Huntsville, AL 35824 USA

Web Support: www.cdielectronics.com •Tech Support: 1-866-423-4832 •Order Parts: 1-800-467-3371

All rights reserved. Reproduction or use of content, in any manner, without express written permission by CDI Electronics, LLC., is prohibited.

Rev D •6/19/2023 Page - 3 of 4 QF-358

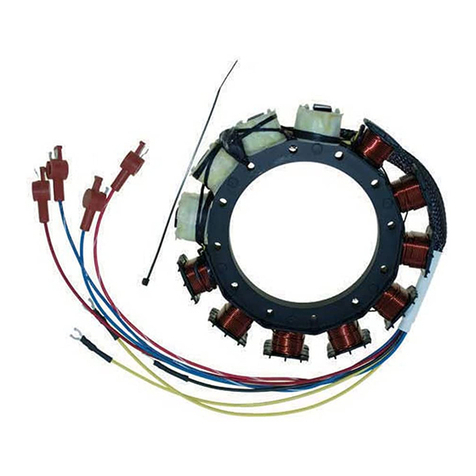

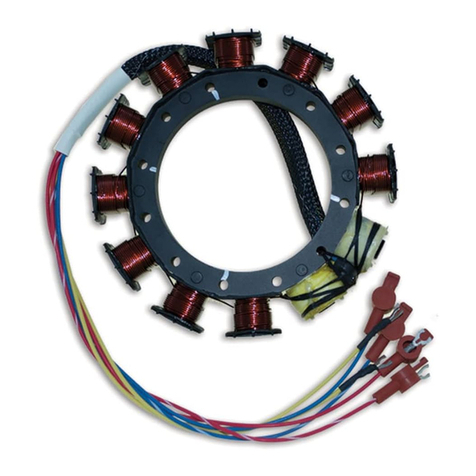

3. Connect a DVA meter between the Stator’s Blue wire and engine ground. Run the engine up to the RPM where the problem is

occurring. The DVA should increase with RPM. A sharp drop in DVA right before the problem occurs usually indicates a bad Stator.

(Repeat the test from Blue/White to engine ground and compare the readings).

4. Connect a DVA meter between the Stator’s Red wire and engine ground. The DVA should show a smooth climb in voltage and remain

high through the RPM range. A reading lower than on the Blue wire reading indicates a bad Stator. (Repeat the test from Red/White to

engine ground and compare the readings).

5. If all cylinders become intermittent, replace both Switchboxes.

6. Connect an inductive tachometer to each cylinder in turn and try to isolate the problem. If two or more cylinders on the same bank are

dropping out, the problem is likely going to be either the Stator or the Switchbox. A single cylinder dropping spark will likely be a bad

Switchbox or Ignition coil. All cylinders not sparking properly usually indicates a bad Stator.

7. Perform a high-speed shutdown and read the spark plugs. Check for water. A crack in the block can cause a miss at high speed when

the water pressure gets high, but a normal shutdown will mask the problem.

8. Check the Trigger and Stator coil flywheel magnets for cracked, broken, or loose magnets.

MISS AT ANY RPM:

1. Disconnect the Yellow wires from the Stator to the Regulator/Rectifier and retest. If the miss clears, replace the Regulator/Rectifier.

2. Disconnect the Idle Stabilizer (advance module) and reset the timing according to the service manual for your engine. If the problem

clears, discard the Idle Stabilizer as it is not needed.

3. In the water or on a Dynamometer, check the DVA on the Green wires from the Switchbox while connected to the ignition coils. You

should have a reading of at least 150 DVA or more, increasing with engine RPM until it reaches 300-400 DVA maximum. A sharp drop

in DVA right before the miss becomes apparent on all cylinders will normally be caused by a bad Stator. A sharp drop in DVA on less

than all cylinders will normally be the Switchbox or Trigger.

4. Connect an inductive tachometer to each cylinder in turn and try to isolate the problem. A high variance in RPM on one cylinder usually

indicates a problem in the Switchbox or Ignition coil. Occasionally a Trigger will cause this same problem. Check the Trigger DVA (see

NO SPARK OR INTERMITTENT SPARK ON ONE OR MORE CYLINDERS).

5. DVA check the Blue and Blue/White wires in reference to engine ground and do a running test. The voltage should show a smooth

climb and stabilize, gradually falling off at higher RPM's (above 3000). If you see a sudden drop in voltage right before the miss

becomes apparent, the Stator is likely at fault.

6. Check DVA on the Red wires reference to engine ground of the Stator at high speed. readings should show a smooth climb in voltage.

If there is a sudden or fast drop in voltage right before the miss becomes apparent, the Stator is usually at fault. If there is no indication

of the problem, it could be a mechanical problem inside your engine.

NOTE: Use caution when doing this and do not exceed the rated voltage range of your meter.

7. Perform a high-speed shutdown and read the spark plugs. Check for water. A crack in the block can cause a miss at high speed when

the water pressure gets high, but a normal shutdown will mask the problem.

8. Check the Trigger and Stator coil flywheel magnets for cracked, broken, or loose magnets.

9. Rotate the Stator one bolt hole in either direction and re-test. If the miss is gone, leave the Stator as is. If the miss is worse, rotate the

Stator back where it was.

NO SPARK WITH THE SPARKPLUGS INSTALLED:

1. Check for a dragging starter or low battery that would cause slow cranking speed. Check the DVA of Stator and Trigger (see NO

SPARK ON ANY CYLINDER).

2. Disconnect the Voltage Regulator and retest. If the problem goes away, replace the Voltage Regulator.

SPARK ON ALL CYLINDERS BUT ENGINE WILL NOT RUN:

1. Check Ignition Timing for #1 Cylinder. Remember the Yellow banded leads go to cylinders 2, 4 & 6. and the Black banded leads go to

cylinders 1, 3 and 5. The Green Coil Primary leads could be swapped as well causing the engine to fire out of time.

2. Index the flywheel for all cylinders. ALL Cylinders should have approximately the same Ignition timing offset as # 1 Cylinder. If they are

not, this would indicate a problem with the Bias Circuitry inside the Switchboxes, the Trigger, or the Trigger magnet of the flywheel.

3. Check the Resistance on each Switchbox’s White/Black wire, reference to engine ground while disconnected. You should read 13-15K

Ωon each Switchbox. If there is over a 10% variance between the two Switchboxes, replace BOTH Switchboxes as a set.

4. Check Ignition Timing on all cylinders. If the Ignition Timing varies, replace both of the Switchboxes as a set.

WILL NOT IDLE BELOW 1500 RPM:

1. Check the Bias resistance from the Black/White terminal (wire disconnected) on the Switchbox to engine ground. Reading should be

13-15K Ω.

2. Check the Stator and Trigger Resistance and DVA (see NO SPARK ON ANY CYLINDER).

3. Check for air leaks.