Norac UC5 Topcon X30 User manual

Other manuals for UC5 Topcon X30

55

Table of contents

Other Norac Control System manuals

Norac

Norac SPRA-COUPE 7000 Series User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC4+ User manual

Norac

Norac UC5 Topcon X30 User manual

Norac

Norac UC5 MAX User manual

Norac

Norac UC5 Active Roll Control User manual

Norac

Norac UC7 User manual

Norac

Norac UC4 Total Control User manual

Norac

Norac UC4.5 User manual

Norac

Norac UC7 User manual

Norac

Norac UC5 Can Bus User manual

Norac

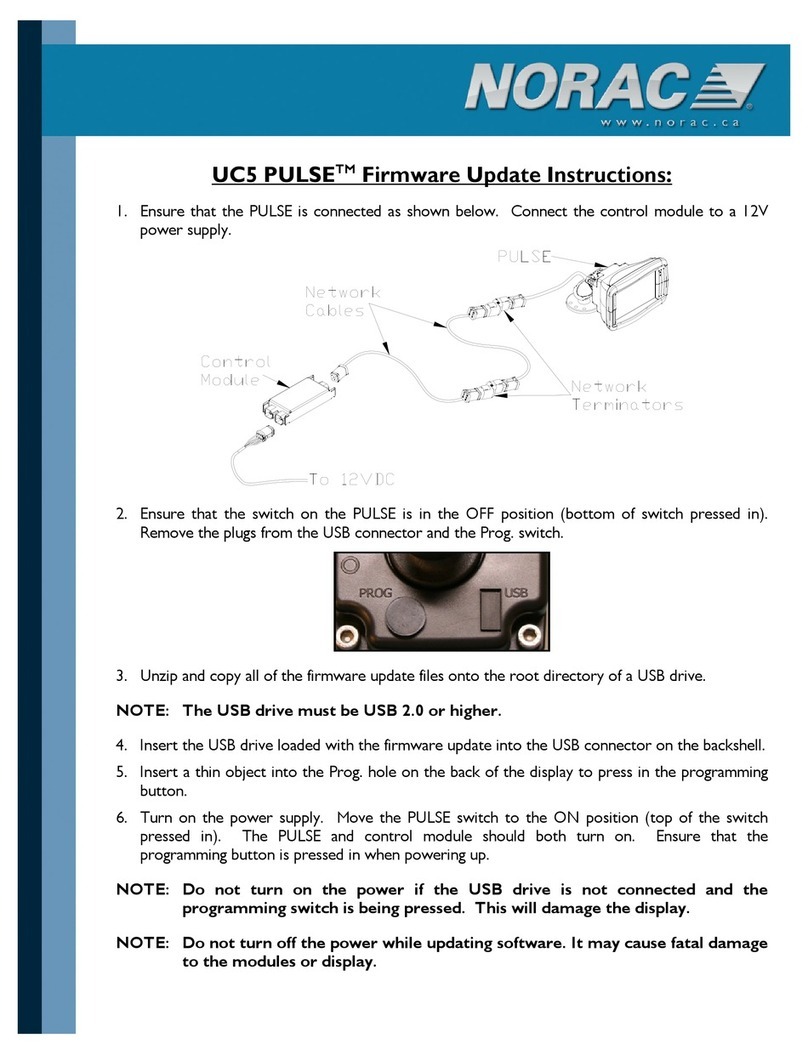

Norac PULSE UC5 Use and care manual

Popular Control System manuals by other brands

SIMDID

SIMDID DH728 Product instruction manual

Skov

Skov DA 3800 Mounting guide

Motorisation+

Motorisation+ X-TRA4 Instructions and warnings for installation and use

adept technology

adept technology SmartMotion installation guide

Woodward

Woodward 505HT Installation and operation manual

Vivotek

Vivotek SC8131 user guide

Festo

Festo CMCA-...-B Series Electrical installation

Airtecnics

Airtecnics CLEVER CONTROL V3 Installation and operation manual

Biamp

Biamp Vocia CI-1 Operation manual

RDT

RDT FloodMaster RS-094-MK4 Install manual

Atmos

Atmos ACD 03 Operation manual

Magnetic

Magnetic MHTM MicroDrive Access XL2 operating instructions

ETC

ETC Echo Inspire Station Programming guide

Beninca

Beninca EVA 5 Installation

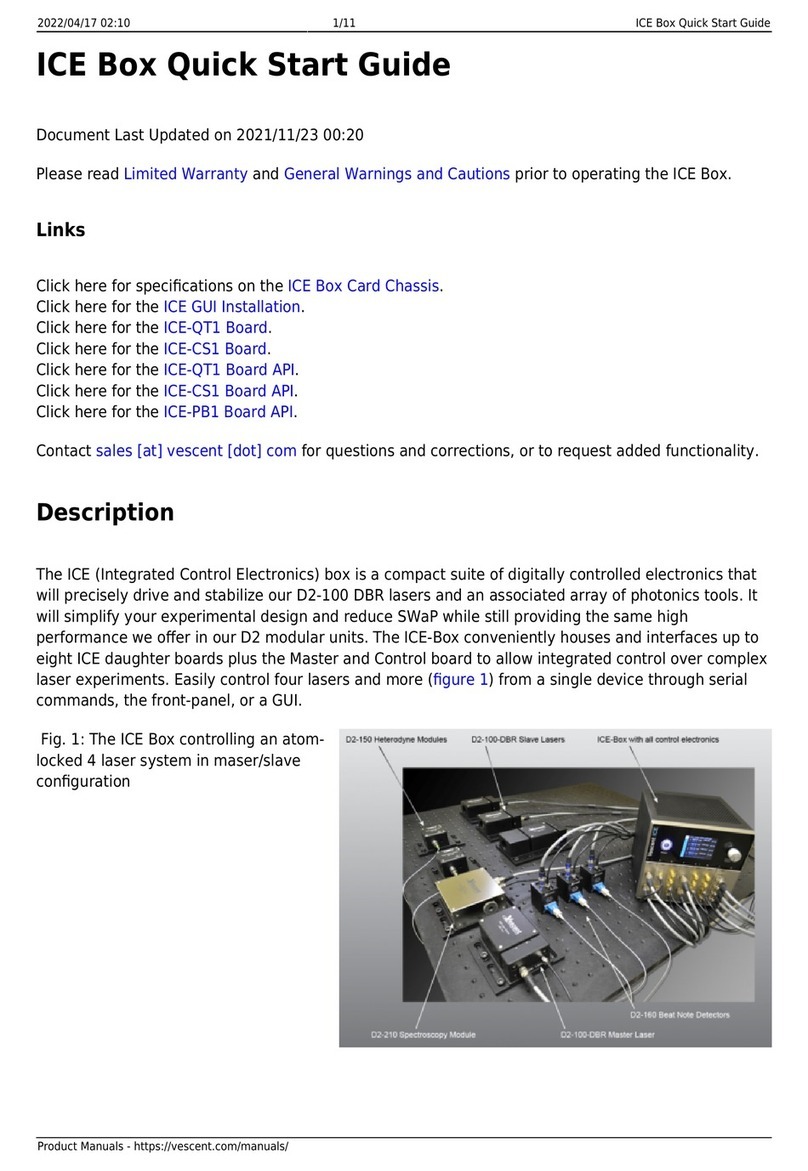

Vescent

Vescent ICE quick start guide

EKOVENT

EKOVENT EKO-KE2 manual

Alpha Communications

Alpha Communications TekTone Tek-CARE NC110A Operation, installation and service manual

Panasonic

Panasonic Imagechecker P400 Specifications