Rhino SD2/XD2 Two-Hand Operation J-Box Module with Ethernet 5

Part 1615331−01

E2019 Nordson Corporation

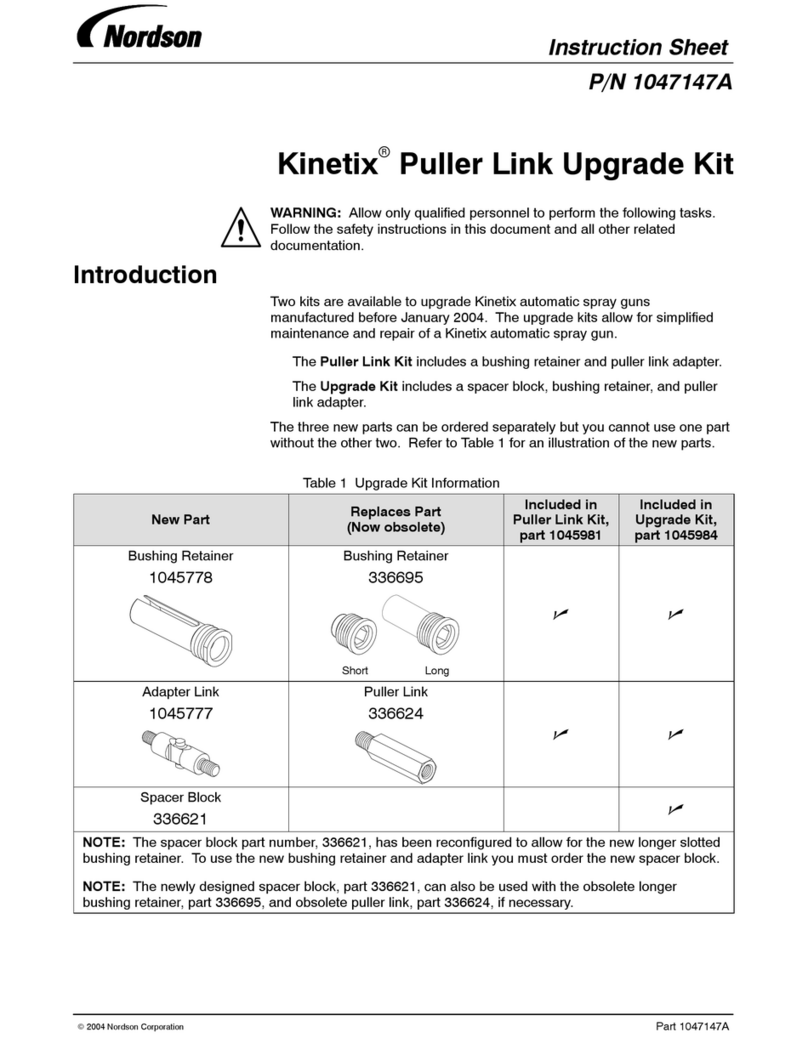

Item Part Description Quanti

ty

Note

— 1613457 MODULE, J-Box, Rhino two-hand 1

1−−−−−− SJUNCTION BOX, Rhino, 2-hand, LT, CE 1

2 983409 SWASHER, lock, M, split, M6, steel, zinc 4

3 984703 SNUT, hex, M6, steel, zinc 4

4 1046023 SCABLE ASSEMBLY, 4 conductor, 1 m, male/fem, 18 AWG, 250V 4

5 1044427 SCABLE ASSEMBLY, 4 conductor, 2 m, male/fem, 18 AWG, 250V 3

6 324289 SSTRAP, cable, 0.06-4.00, black 12

7−−−−−− SKIT, label, cable, J-box, Rhino, 2-hand, CE 1

8 1045884 SCABLE, 4-pin Micro DC, 18 AWG, 4 m, male/female 1

NS 939004 SSTRAP, cable, 0.06-1.75, natural, 12260-4 12

Schematic

See Figure 4-7 and refer to Table 2 for the DeviceNet Input/Output signal descriptions.

Table 2 DeviceNet Inputs/Outputs

Input Description

Purge Button Enables the inactive air motor on a crossover unloader system to be cycled for a drum

change or material purge.

Drum Empty Sends a signal to the system controller to disable the air motor when the follower plate

reaches the bottom of the material a container.

Drum In Position Sends a signal to the system J−Box that a drum is positioned below the follower.

Stroke Proximity Monitors pump strokes, cycles, and runaway conditions.

Follower In Drum Indicates that the follower is in the drum and enables downward ram movement.

Ram Up Switch Enables upward ram movement.

Ram Down Switch Enables downward ram movement.

2-Hand Control Enables the ram movement circuit.

Output Description

Air Motor Receives signals from the system controller to the air motor.

Blowoff Solenoid Receives signals from the system controller to control the flow of air underneath the follower

plate when removing the material drum from the bulk unloader.

Ram Up and

Down Solenoids

Ram Up/Down Control Valve: Receives signals from the system controller to control ram

movement:

SRam Up raises the ram and follower plate.

SNeutral stops ram movement and pneumatically locks the rams.

SRam Down lowers the ram and follower plate.

NOTE: The Neutral position does not mechanically lock the ram. Air pressure remains in the

ram cylinders. Small air leaks in the circuit can cause the ram to drift upward or downward.

Never leave the bulk unloader in the Neutral position to perform maintenance, or when it is

not in use for long periods of time. When performing maintenance, make sure that the ram

and follower plate is on the bulk unloader base or secured using support blocks.