5

Operation

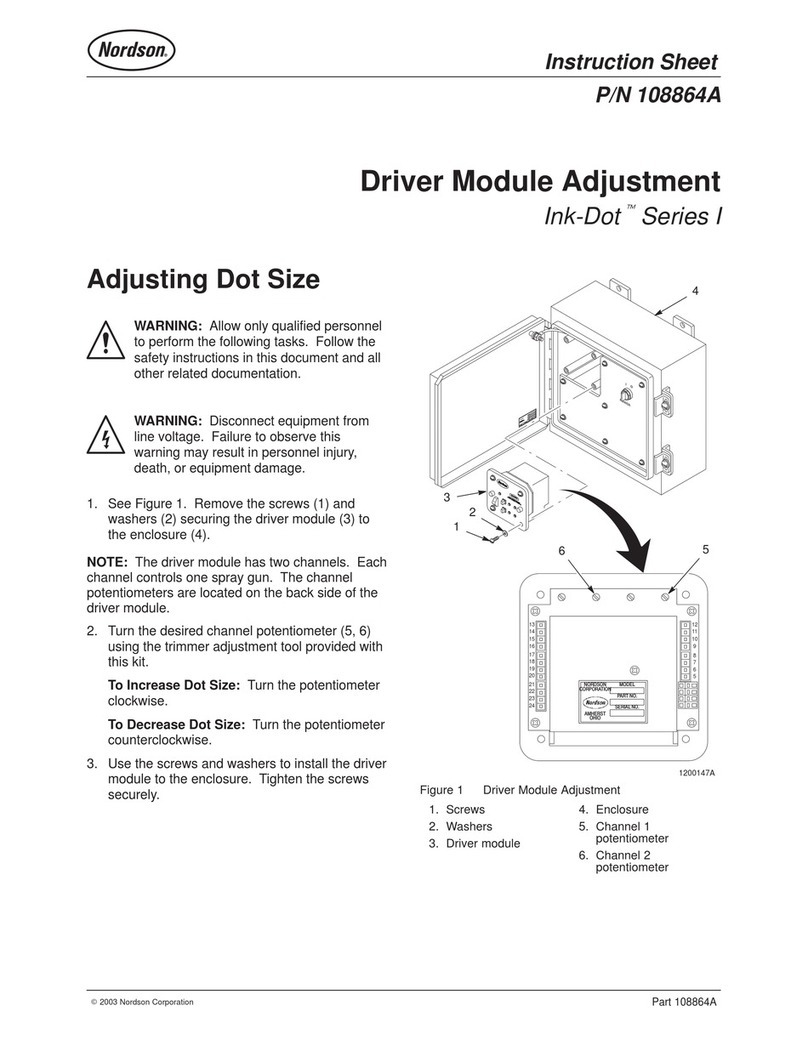

See Figure 1.

NOTE: The break-in period for the valve seat is the

first 10-24 hours of operation. If the dot size

increases, refer to Dot Size Adjustment.

Startup

1. Open the air shut-off valve (21).

2. Set the air pressure regulator (20) to

0.4-0.7 bar (5-10 psi).

3. Turn on the Ink-Dot controller power switch (9).

4. Turn on the driver power switch (7).

5. Set the RUN/OFF/TEST switch (6) to RUN.

6. If desired, adjust the dot size. Refer to Dot Size

Adjustment

Changing Materials

1. Close the air shut-off valve (21)

2. Set the air pressure regulator (20) to 0 bar/psi.

Pull the relief valve (19) lanyard to relieve system

air pressure.

3. Place a waste container under the drain valve

(17) and open the drain valve. Allow the ink to

drain from the reservoir (18) into the container.

When the ink has drained from the reservoir close

the drain valve.

4. See Figure 2. Unscrew the cap from the

reservoir (1) and fill with a 1/2quart of compatible

solvent. Install the cap (2).

5. Perform a solvent flush. Refer to Initial Startup

and perform steps 6–12.

6. Fill the rervoir with ink. Refer to Filling the

Reservoir.

Shutdown

CAUTION: Failure to turn off the

RUN/OFF/TEST switch can cause damage

to the gun nozzle and ball and seat

assembly.

See Figure 1.

1. Set the RUN/OFF/TEST switch (6) to OFF.

2. Turn off the driver power switch (7).

3. Turn off the controller power switch (9).

4. Turn off the air supply link to the reservoir by

closing the air shut-off valve (21).

5. Set the air pressure regulator (20) to 0 bar/psi.

Pull on the relief valve (19) lanyard to relive

system air pressure.

Dot Size Adjustment

See Figure 1. Follow these steps to adjust the dot

size from the Ink-Dot electric spray gun.

1. Set the RUN/OFF/TEST switch (6) in the Ink-Dot

control unit to OFF.

2. Set the air pressure regulator (20) to

0.5 bar (7 psi) at the ink reservoir.

3. Loosen the locknut (13).

4. Carefully screw in the armature sleeve (12) until it

stops or bottoms out.

5. Unscrew the armature sleeve approximately 1/12

of a turn or 30_.

6. Hold a piece of paper by the bottom of the can

and in line with the nozzle (11).

7. Set the RUN/OFF/TEST switch (6) in the

Ink-Dot control unit to TEST. Adjust the

armature sleeve (12) until the dot is the desired

size, typically 2–3 mm.

NOTE: Do not hold the armature sleeve screw with

the screwdriver while you are tightening the locknut.

8. Use a 1/2-in. wrench to tighten the locknut.

NOTE: The dot size will become slightly larger when

tightening the locknut.

9. If desired, change the fluid pressure to make fine

adjustments to the dot size:

SIncrease the pressure for a larger dot.

SDecrease the pressure for a smaller dot.

NOTE: Refer to the Ink-Dot Series II Driver manual

to make additional adjustments to the dot size using

the dip switches.