1

English

English

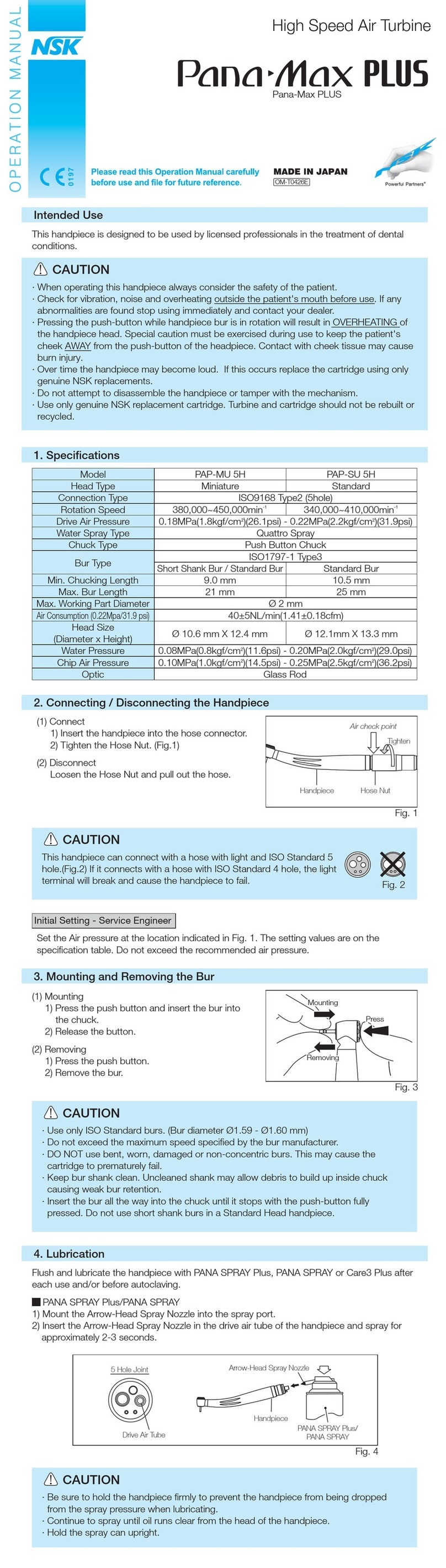

Contents

1. User and Indications for Use ................... 2

2. Precautions for Handling and Operation ... 2

3. Product Description ............................... 6

3–1 Package contents ���������������������������������������� 6

3–2 Control unit, motor handpiece ����������������������� 7

3–3 Control panel ����������������������������������������������� 8

4. Preparation for Use .............................. 12

4–1 Connecting AC adaptor ������������������������������� 12

4–2 Charge (If the battery is used) ��������������������� 12

4–3 Attaching barrier film ��������������������������������� 13

4–4 Connecting and disconnecting the motor

handpiece ������������������������������������������������� 13

4–5 Connecting and disconnecting the contra

angle head ������������������������������������������������ 14

4–6 Inserting and removing the file �������������������� 15

4–7 Check before treatment ������������������������������ 16

5. Operation Procedure ............................ 18

5–1 Standard operation ������������������������������������� 18

5–2 Auto reverse function ��������������������������������� 19

5–3 Programs �������������������������������������������������� 21

5–4 Alarm sound volume control ������������������������ 21

5–5 Initialization of program (factory-set

configuration) �������������������������������������������� 22

6. Post-use Maintenance .......................... 23

6–1 Preparation for maintenance ����������������������� 23

6–2 Cleaning and disinfection ���������������������������� 23

6–3 Lubrication ������������������������������������������������ 28

6–4 Sterilization ����������������������������������������������� 28

6–5 Storage ����������������������������������������������������� 29

7. Maintenance ........................................ 30

7–1 Battery refresh ������������������������������������������ 30

7–2 Changing the battery ���������������������������������� 31

7–3 Periodical Maintenance Checks ������������������� 32

8. Troubleshooting ................................... 33

8–1 Error code ������������������������������������������������� 33

8–2 Problems and actions ��������������������������������� 34

9. After-sales Service ............................... 36

9–1 Warranty ��������������������������������������������������� 36

9–2 Spare parts list ������������������������������������������ 36

9–3 Option parts list ����������������������������������������� 36

9–4 Disposing product �������������������������������������� 37

10. Specifications ...................................... 38

10–1 Specifications �������������������������������������������� 38

10–2 Classification of equipment ������������������������� 39

10–3 Operation principle ������������������������������������� 39

10–4 Symbol ����������������������������������������������������� 40

11. EMC Information (Electromagnetic

Compatibility Information) .................... 41