NSK Ti-Max X95L Use and care manual

Other NSK Dental Equipment manuals

NSK

NSK NAC-Y User manual

NSK

NSK Ti-max Z45L User manual

NSK

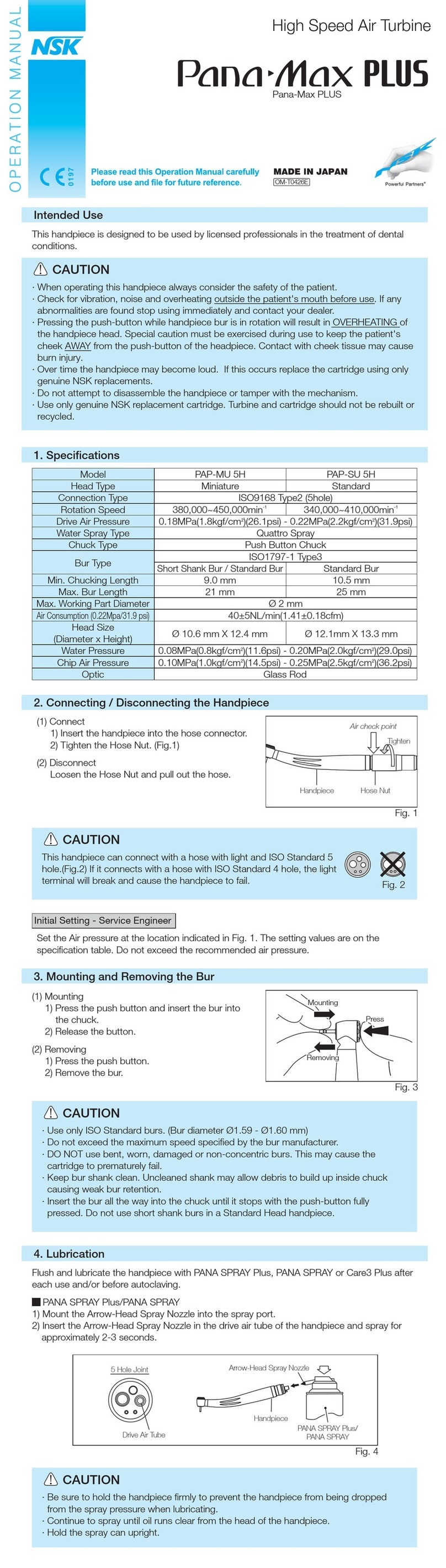

NSK Pana-Max PLUS PAP-MU 5H User manual

NSK

NSK Ti-Max Ti-SG65L User manual

NSK

NSK TI-MAX X35L User manual

NSK

NSK EX Series User manual

NSK

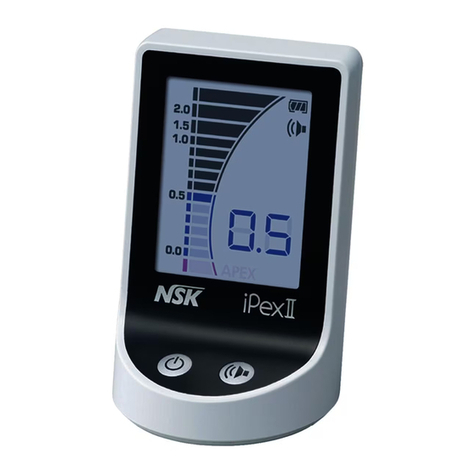

NSK iPexII User manual

NSK

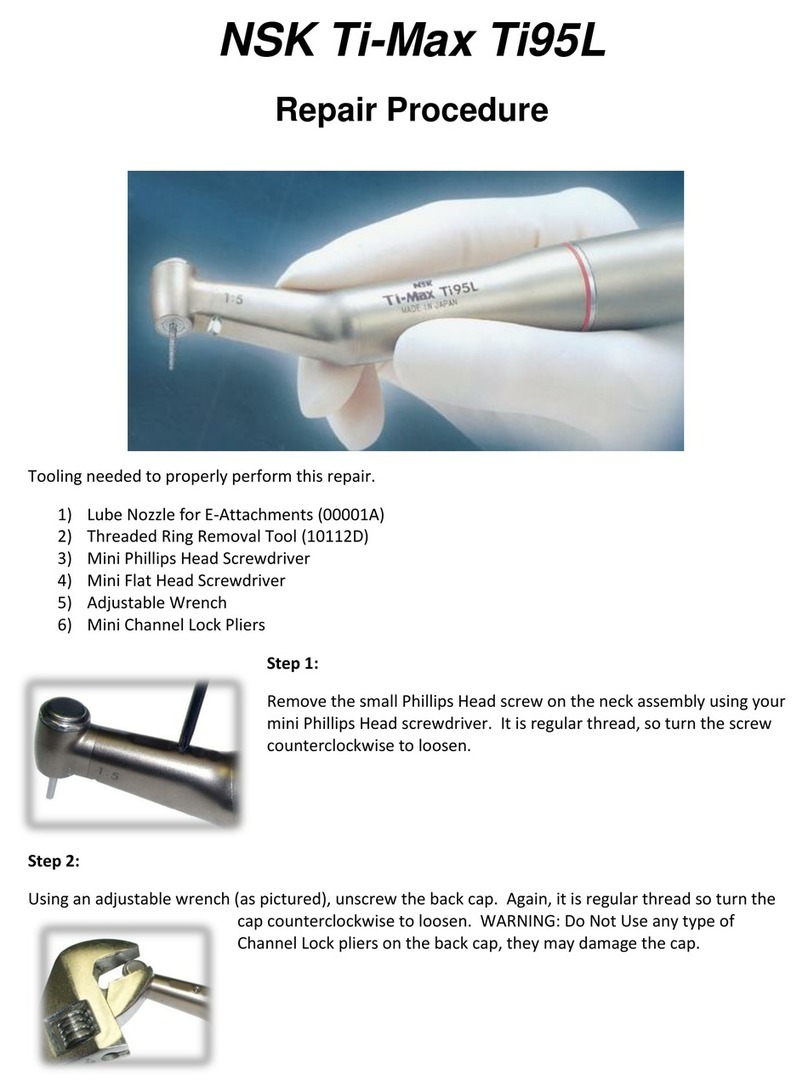

NSK Ti-Max Ti95L Manual

NSK

NSK Ti-Max nano65LS User manual

NSK

NSK BB Series User manual