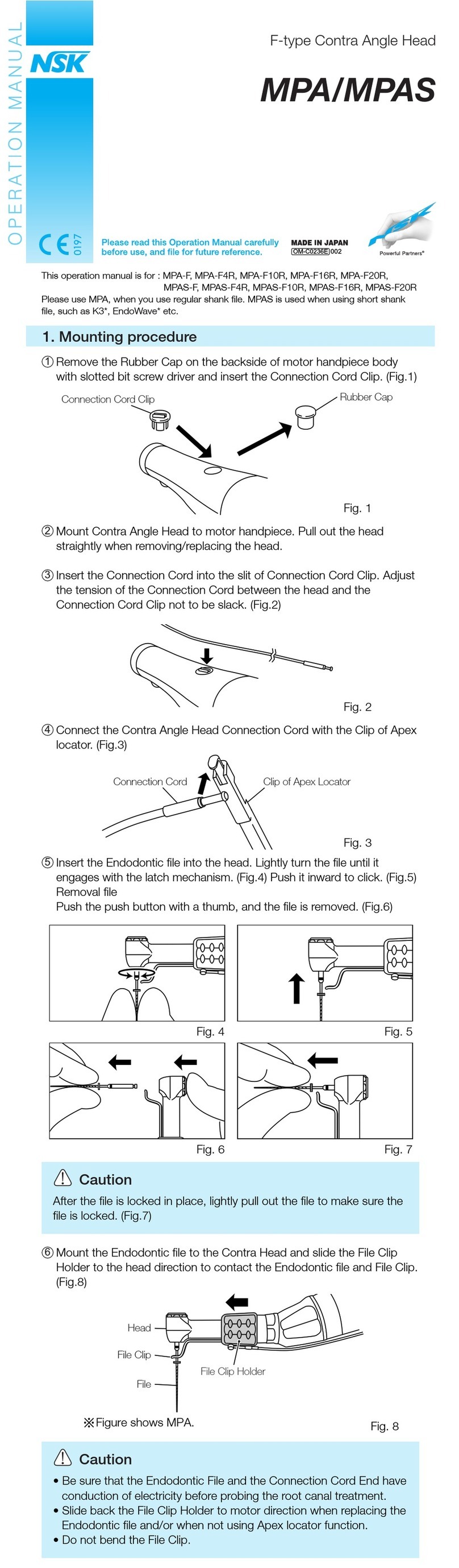

CAUTION

CAUTION

· When operating this handpiece always consider the safety of the patient.

· Check for vibration, noise and overheating outside the patient's mouth before use. If any

abnormalities are found stop using immediately and contact your dealer.

· Pressing the push-button while handpiece bur is in rotation will result in OVERHEATING of

the handpiece head. Special caution must be exercised during use to keep the patient's

cheek AWAY from the push-button of the headpiece. Contact with cheek tissue may cause

burn injury.

· Over time the handpiece may become loud. If this occurs replace the cartridge using only

genuine NSK replacements.

· Do not attempt to disassemble the handpiece or tamper with the mechanism.

· Use only genuine NSK replacement cartridge. Turbine and cartridge should not be rebuilt or

recycled.

1. Specifications

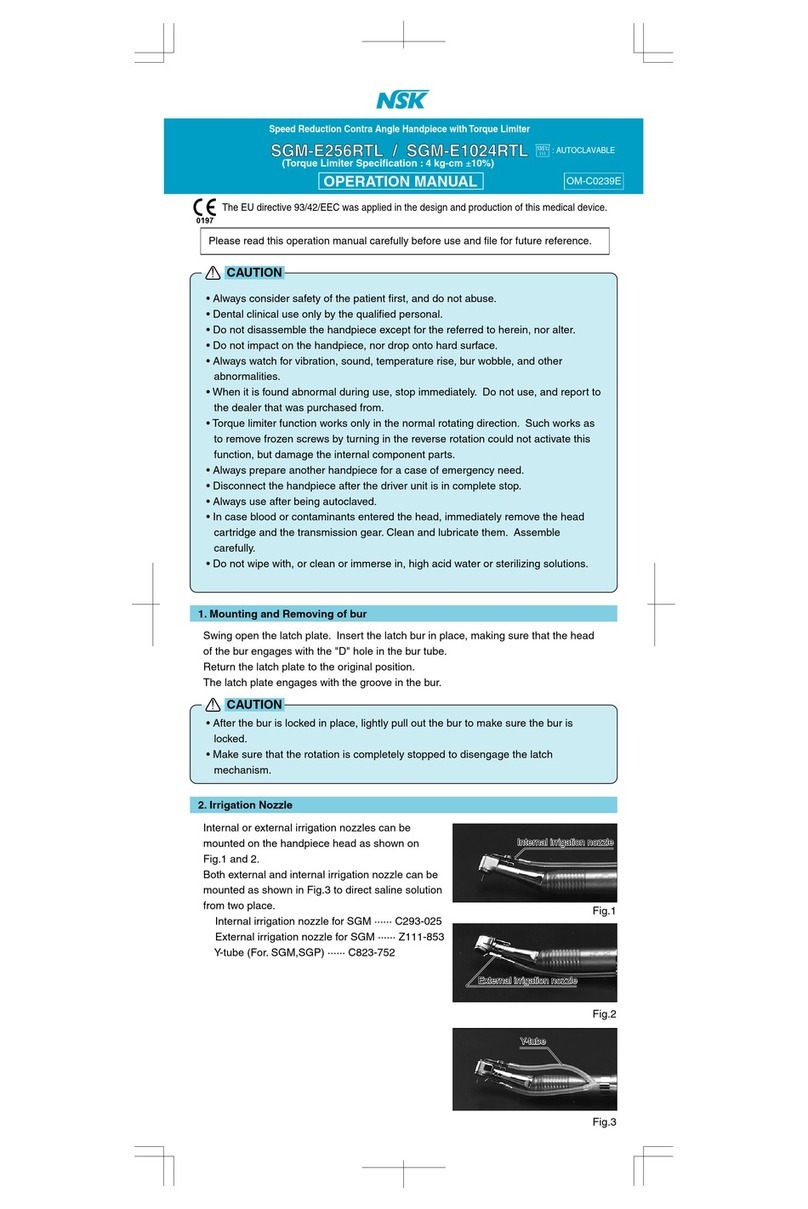

2. Connecting / Disconnecting the Handpiece

(1) Connect

1) Insert the handpiece into the hose connector.

2) Tighten the Hose Nut. (Fig.1)

(2) Disconnect

Loosen the Hose Nut and pull out the hose.

Intended Use

This handpiece is designed to be used by licensed professionals in the treatment of dental

conditions.

Fig. 1

OM-T0426E

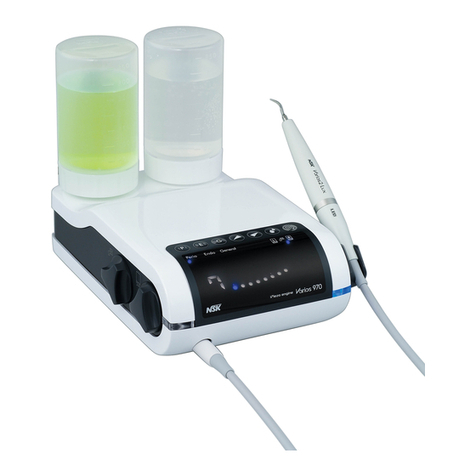

High Speed Air Turbine

3. Mounting and Removing the Bur

(1) Mounting

1) Press the push button and insert the bur into

the chuck.

2) Release the button.

(2) Removing

1) Press the push button.

2) Remove the bur.

Fig. 3

CAUTION

This handpiece can connect with a hose with light and ISO Standard 5

hole.(Fig.2) If it connects with a hose with ISO Standard 4 hole, the light

terminal will break and cause the handpiece to fail.

· Use only ISO Standard burs. (Bur diameter Ø1.59 - Ø1.60 mm)

· Do not exceed the maximum speed specified by the bur manufacturer.

· DO NOT use bent, worn, damaged or non-concentric burs. This may cause the

cartridge to prematurely fail.

· Keep bur shank clean. Uncleaned shank may allow debris to build up inside chuck

causing weak bur retention.

· Insert the bur all the way into the chuck until it stops with the push-button fully

pressed. Do not use short shank burs in a Standard Head handpiece.

Standard Bur

10.5 mm

25 mm

Short Shank Bur / Standard Bur

9.0 mm

21 mm

PAP-SU 5H

Standard

PAP-MU 5H

Miniature

340,000~410,000min-1

ISO9168 Type2 (5hole)

0.08MPa(0.8kgf/cm2)(11.6psi) - 0.20MPa(2.0kgf/cm2)(29.0psi)

0.10MPa(1.0kgf/cm2)(14.5psi) - 0.25MPa(2.5kgf/cm2)(36.2psi)

Glass Rod

Ø 2 mm

40±5NL/min(1.41±0.18cfm)

0.18MPa(1.8kgf/cm2)(26.1psi) - 0.22MPa(2.2kgf/cm2)(31.9psi)

Quattro Spray

Push Button Chuck

ISO1797-1 Type3

Model

Head Type

Connection Type

Rotation Speed

Drive Air Pressure

Water Spray Type

Chuck Type

Bur Type

Min. Chucking Length

Max. Bur Length

Max. Working Part Diameter

Air Consumption (0.22Mpa/31.9 psi)

Head Size

(Diameter x Height)

Water Pressure

Chip Air Pressure

Optic

380,000~450,000min-1

Ø 12.1mm X 13.3 mm

Initial Setting - Service Engineer

Set the Air pressure at the location indicated in Fig. 1. The setting values are on the

specification table. Do not exceed the recommended air pressure.

CAUTION

· Be sure to hold the handpiece firmly to prevent the handpiece from being dropped

from the spray pressure when lubricating.

· Continue to spray until oil runs clear from the head of the handpiece.

· Hold the spray can upright.

Ø 10.6 mm X 12.4 mm

4. Lubrication

Flush and lubricate the handpiece with PANA SPRAY Plus, PANA SPRAY or Care3 Plus after

each use and/or before autoclaving.

PANA SPRAY Plus/PANA SPRAY

1) Mount the Arrow-Head Spray Nozzle into the spray port.

2) Insert the Arrow-Head Spray Nozzle in the drive air tube of the handpiece and spray for

approximately 2-3 seconds.

Fig. 4

Fig. 2

Pana-Max PLUS

Air check point

Hose NutHandpiece

Tighten

Mounting

Removing

Mounting

Press

Press

Removing

5 Hole Joint

PANA SPRAY Plus/

PANA SPRAY

Arrow-Head Spray Nozzle

Handpiece

Drive Air Tube