OM0123 Page 4 of 68

Rev 15

1.3 CO2Display and Control

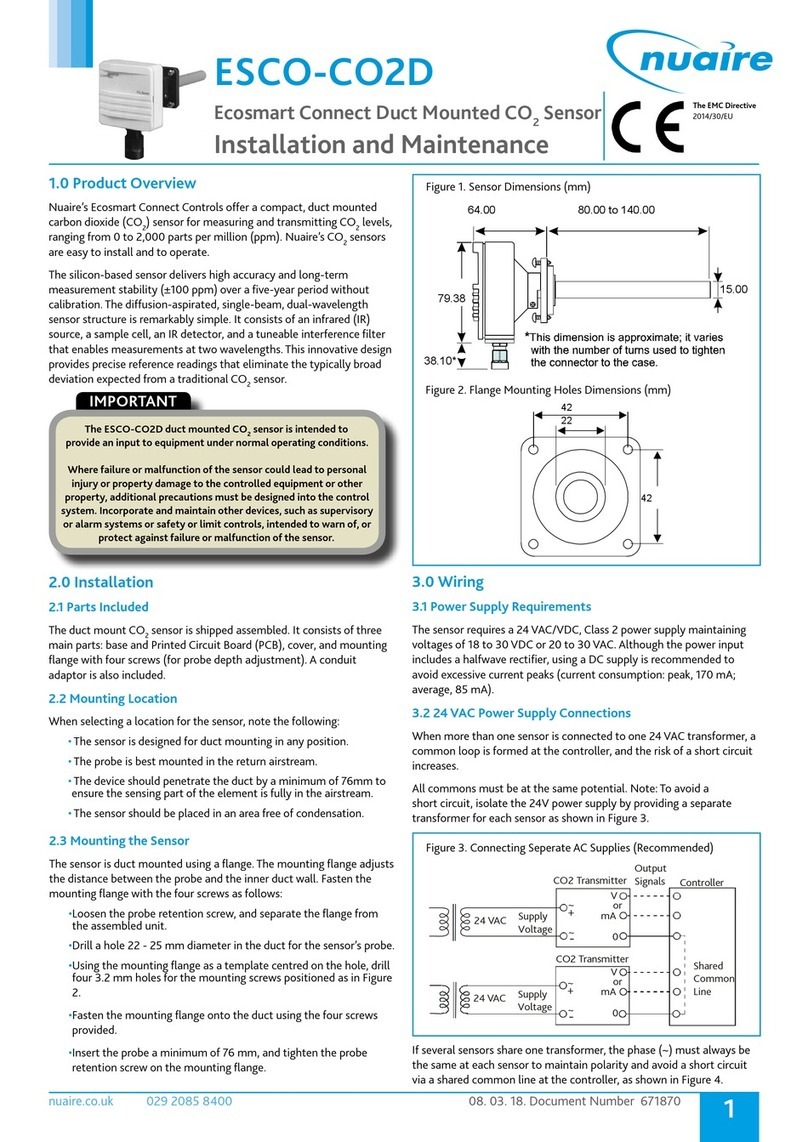

The NuAire US Autoflow employs a solid-state single gas analyzer for carbon dioxide. This innovative analyzer

utilizes a filter correlation technique for non-dispersive infrared analysis of CO2. The analyzer consists of an

optical bench incorporating an infrared source, sample cell, and infrared detector. The amount of power

radiating on the detector is an approximate logarithmic function of the CO2concentration in the gas between

source and detector. Detector linearization is performed with 32-bit digital accuracy. The measurement of

CO2is independent of humidity and temperature variations within the chamber.

1.4 All Stainless Steel Construction

The US Autoflow's exterior is constructed of 16 gauge, type 304L stainless steel with the interior being 16

gauge, type 304L polished stainless steel using coved corner construction, which provides an easily cleanable

(for decontamination) inert surface that does not promote biological growth. All exposed edges are deburred

to insure no sharp edges. The exterior is finished in a textured polyurethane finish, which is resistant to

chemicals and easily cleaned using mild household detergents. In addition all shelves, shelf supports and

guide rails are easily removable and can be autoclaved to remove contamination.

1.5 Relative Humidity Display and Control (NU-4850, NU-4950)

Conventionally, humidification of the chamber is achieved through the process of water evaporation from a

water reservoir pan placed in the chamber. The NU-4850 & NU-4950 models humidify the chamber by

injecting a heated water vapor from a reservoir located outside of the chamber. This gives the operator

control over the amount of humidity in the chamber from below ambient to 95%. After a door opening, the

recovery time to 95% +3% is 10 minutes on average with all settings at default values. The control system has

a +3% accuracy from any given setpoint.

The control system uses a solid-state capacitance humidity sensor to monitor the relative humidity within the

chamber. If humidity is required, the control system will activate solenoid valve. The pump will then draw

chamber air to itself, through a humidified heated enclosure and returned to the chamber. The control will

continue until the setpoint is achieved. The relative humidity display and control option offers an accurate

and reliable method to control humidity when required.

1.6 O2Display and Control (NU-4950)

The US AutoFlow has an available optional Oxygen display and control system. The system controls from 21%

(ambient level) down to 2%. The recovery time from ambient to 5% ±2% is typically less than 10 minutes.

The accuracy is ±1% from any given set point.

Oxygen sensor is a fuel cell type, which generates a linear mVDC signal based on O2content in the chamber.

The sensor is unaffected by CO, H2and various acidic gases such as CO2, H2S, NOx, SOx, etc.

A sensor automatic monitoring is provided to monitor the O2sensor as fuel cell depletes. The automatic

monitoring occurs every 24 hours and lasts 2 minutes. During automatic monitoring events, all the displays

are locked on existing reading. Control keys are also locked. At this time, air inject valve is energized to draw

fresh air through the O2sensor. A new O2span value is stored in memory for use as the 21.0% of O2reference

point. During automatic monitoring, the new span value in mV is also compared with original voltage outputs.

If the current output is less than 70% of original output, an “RPL” replace message is indicated on the O2

display.