OM0253 Page 4 of 52

Rev 9 September/2022

and a display off- set calibration. These calibrations are accessible through the NuTouch LCD located on the front of the

unit.

1.5 All Stainless-Steel Construction

The exterior is constructed of 16-gauge, type 304L stainless steel with the interior being 16-gauge, type 304L polished

stainless steel using coved corner construction, which provides an easily cleanable (for decontamination) inert surface that

does not promote biological growth. All exposed edges are deburred to insure no sharp edges. The exterior is finished in a

textured polyurethane finish, which is resistant to chemicals and easily cleaned using mild household detergents.

In addition, all shelves, shelf supports, and guide rails are easily removable and can be autoclaved to remove

contamination.

Remember: The chamber environment is not selective. The growth environment is applied equally to all microorganisms

(specimens and contaminates) within the chamber.

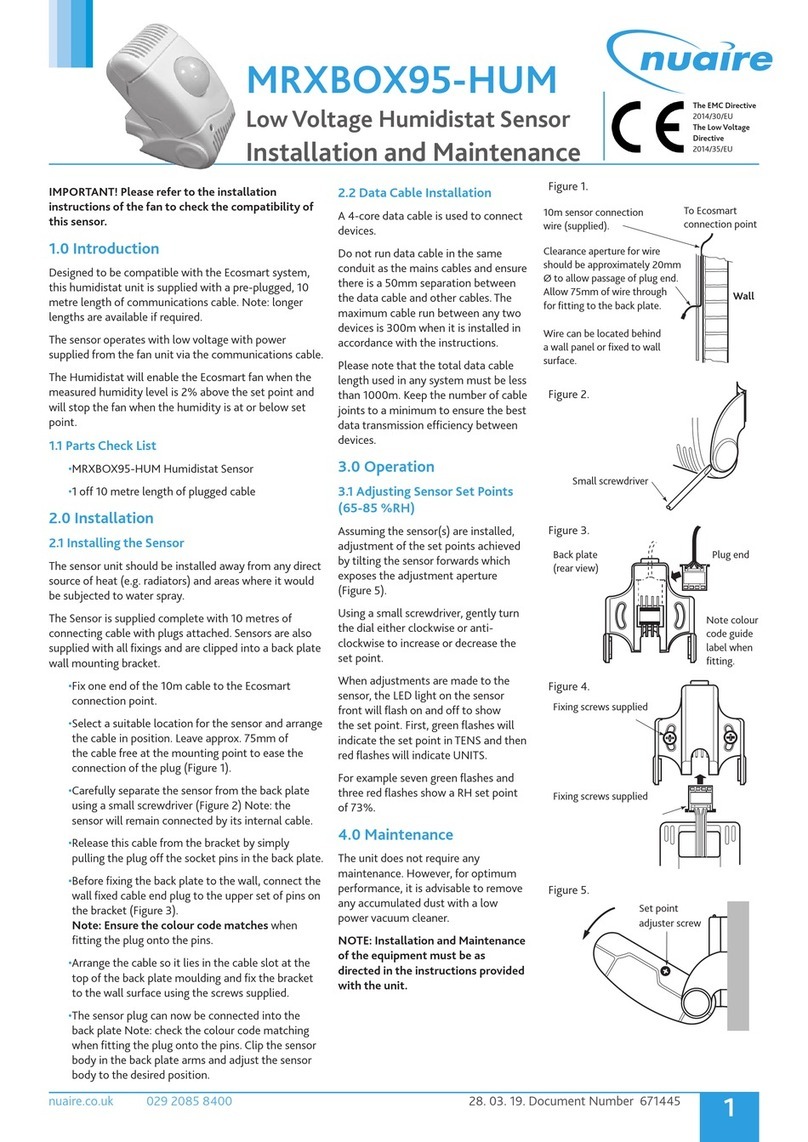

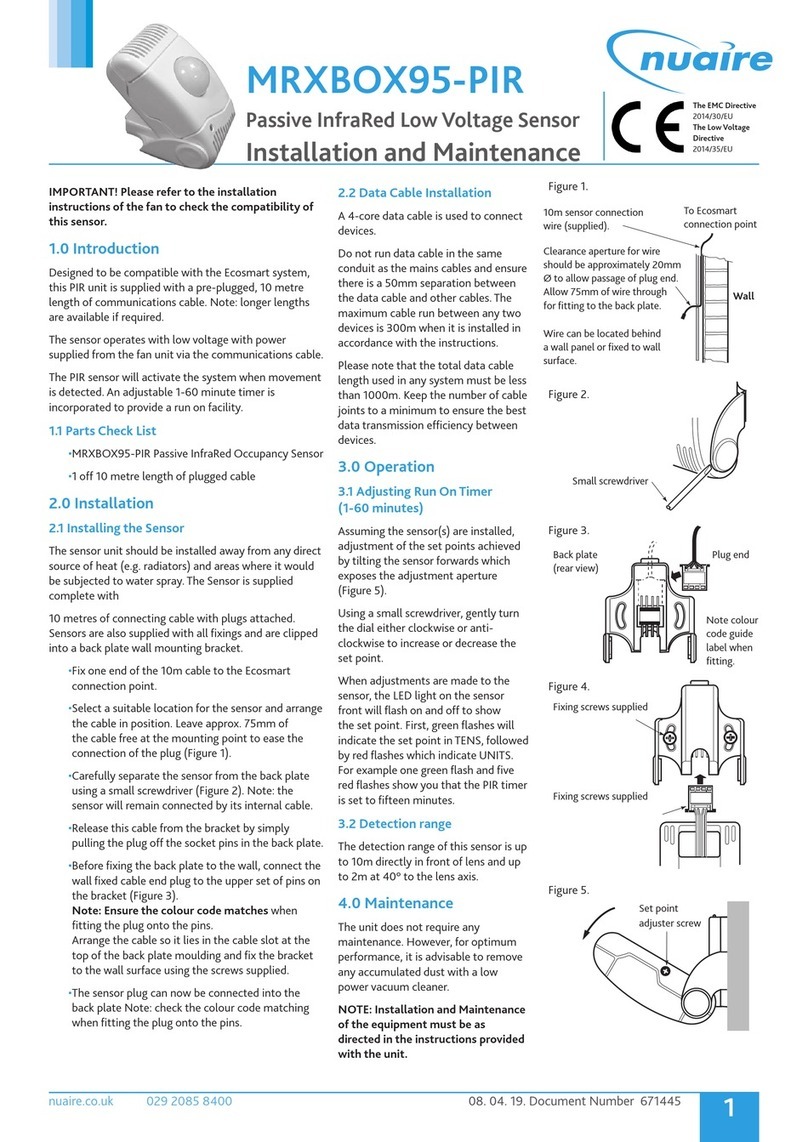

1.6 Incubator Humidity

All Model(s)

A relative humidity level of up to 90% is achieved in the Incubator by the use of a stainless-steel pan filled with distilled

water no purer than 1 mega ohm, and placed on the bottom of the chamber. It is necessary to set the duty cycle of the

door heater in proper proportions to reduce the possibility of condensation forming on the glass inner door and the

chamber walls. It is also important to thoroughly wipe the walls and the glass door clean before adding the humidity water

pan. Condensation will occur more readily at contamination points. There is no electronic sensing and thus no automatic

control of the humidity level in the Water Jacketed Incubator. An air pump injects fresh air into the chamber at a preset

duty cycle to reduce condensation forming on the chamber walls and front glass door. The air injections are settable by the

user to help control condensation. (See section 8.8 for this option.)

1.7 O2Display and Control (NU-8631)

The Incubator has an available optional Oxygen display and control system. The system controls from 21% (ambient level)

down to 0.5%. The recovery time from ambient to 5% 2% is typically less than 15 minutes. The accuracy is 0.25% from

any given set point.

Oxygen sensor is a type, which generates logarithmic signal based on O2content in the chamber. The sensor is unaffected

by CO, H2and various acidic gases such as CO2, etc.

RH Display (NU-8625 and NU-8645)

These Incubators display RH. The system does not control RH, it is just a monitor.

1.8 Safety Instructions

These safety instructions describe the safety features of the In-VitroCell Incubator.

The incubator has been manufactured using the latest technological developments and has been thoroughly tested before

delivery. It may, however, present potential hazards if it is not used according to the intended purpose or outside of

operating parameters. Therefore, the following procedures must always be observed:

•

The incubator must be operated only by trained and authorized personnel.

•

For any operation of this unit, the operator must prepare clear and concise written instructions for operating and

cleaning, utilizing applicable safety data sheets, plant hygiene guidelines, and technical regulations, in particular.

oWhich decontamination measures are to be applied for the incubator and accessories?

oWhich protective measures apply while specific agents are used?

oWhich measures are to be taken in the case of an accident?

•

Repairs to the device must be carried out only by trained and authorized expert personnel.

•

Keep these operating instructions close to the unit so that safety instructions and important information are

always accessible.

•

Should you encounter problems that are not detailed adequately in the operating instructions, please contact your

NuAire Representative or NuAire technical Services.