2

11. 08. 20. Document Number 671794Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA |nuaire.co.uk

DRI-ECO-CO2Installation Manual

2.0 INSTALLATION

Installation must be completed by competent persons, in accordance

with good industry practice and should conform to all governing and

statutory bodies i.e. IEE, CIBSE, etc.

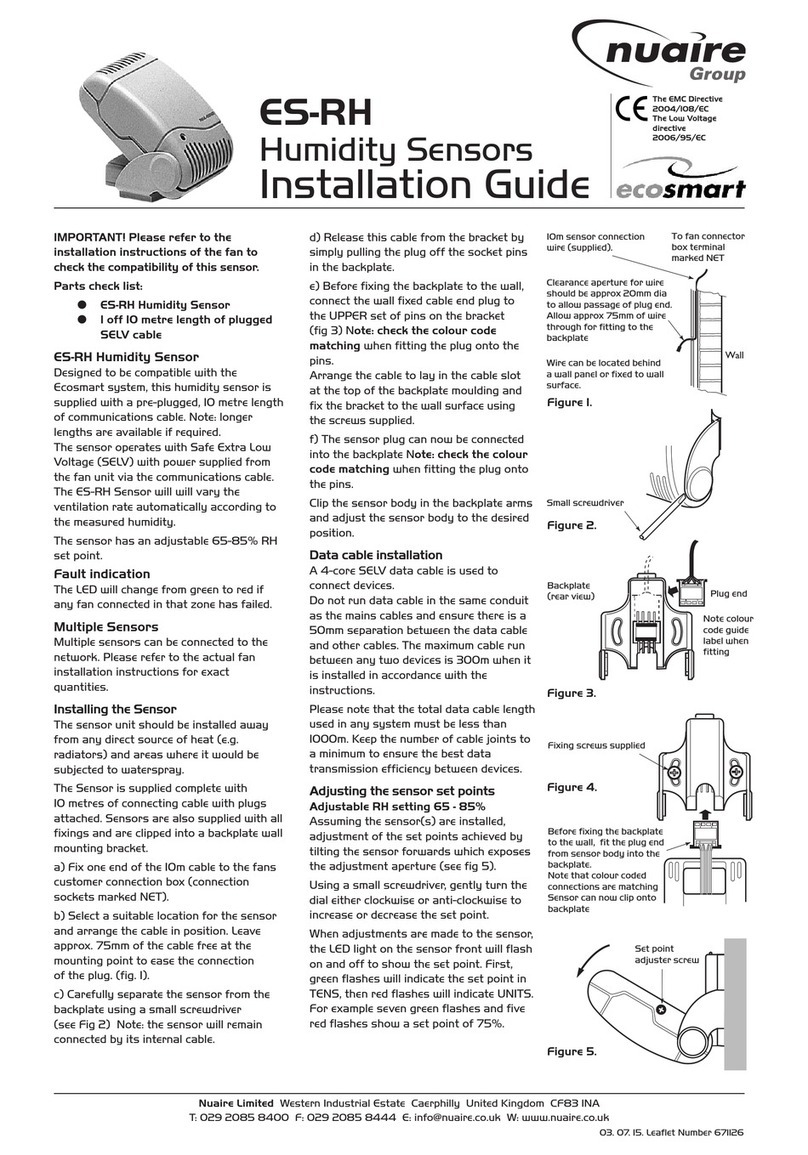

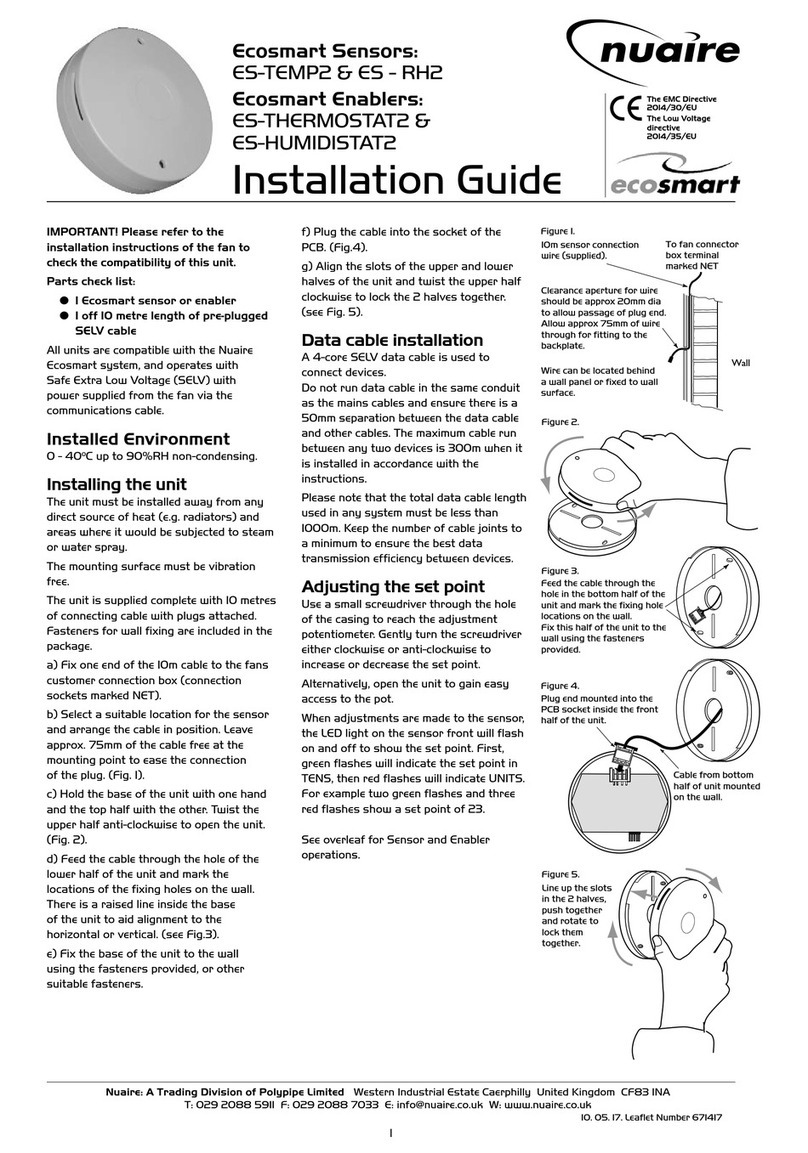

The CO2 sensor requires a 230V power supply. The front panel of the

CO2 sensor must first be released by pressing in the plastic fixing lug

located on the bottom edge of the sensor. The panel may now be

removed allowing access to complete the sensor wiring. Finally the

sensor should be mounted on the wall in a suitable location (screws not

provided).

1 DRI-ECO-CO2

Indent

Button

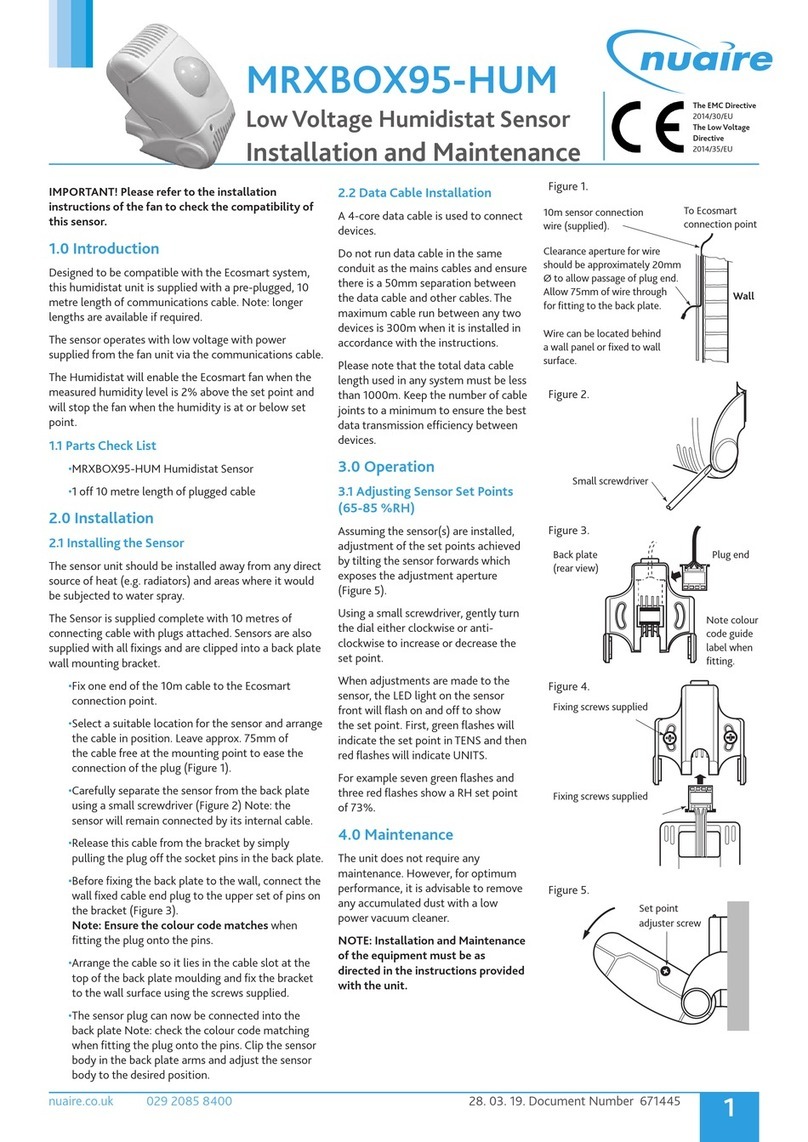

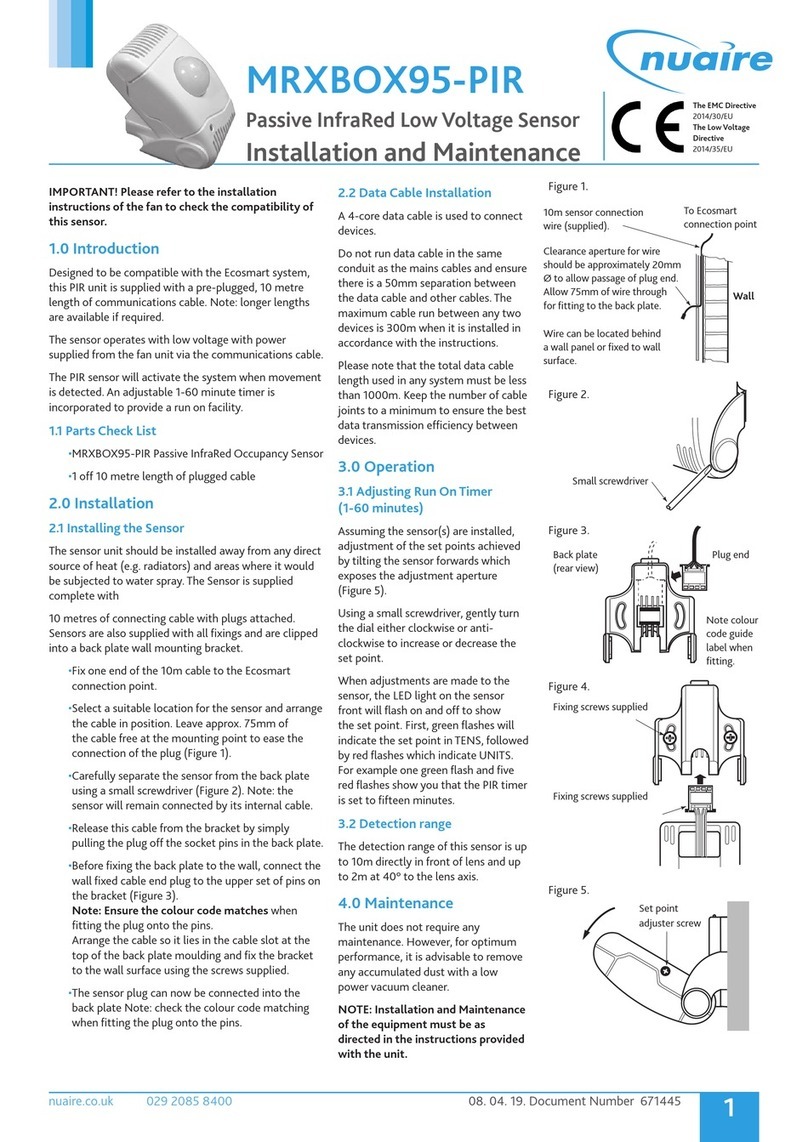

2.1 Wiring Diagram

2 DRI-ECO-CO2 Wiring

L N

CO2

Sensor

Mains

230V

50Hz

4VA

N

L

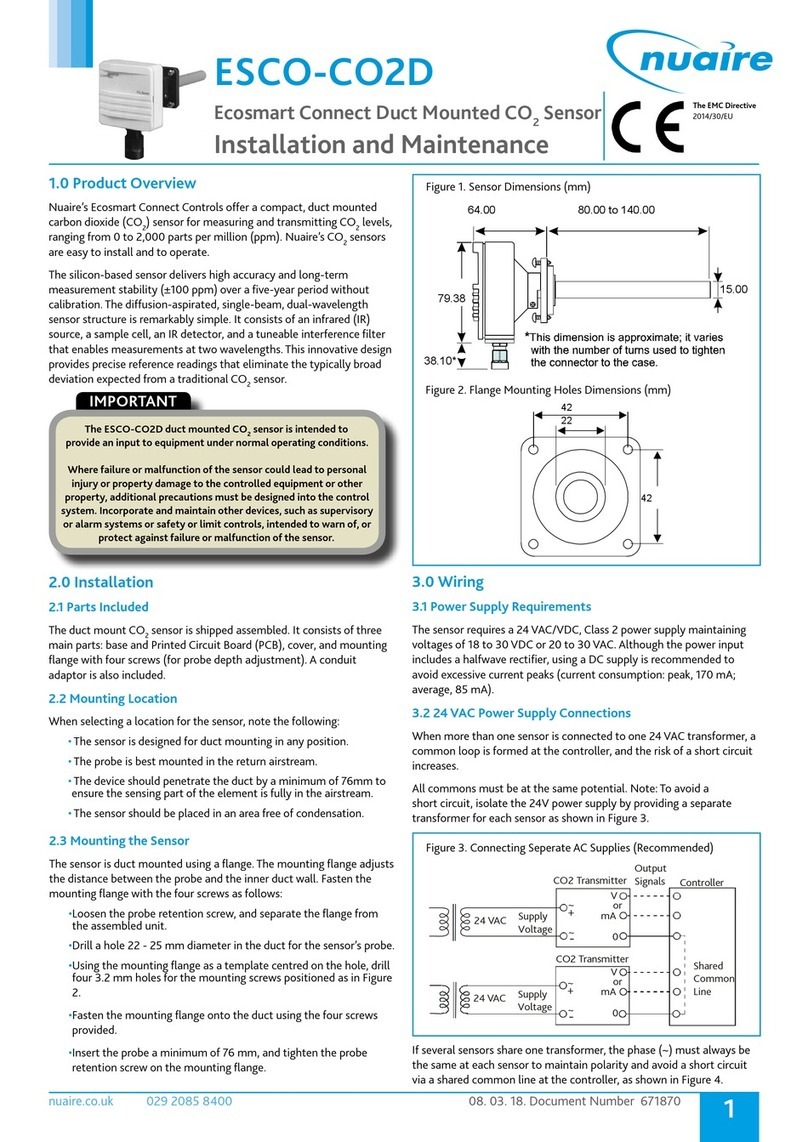

2.2 DRI-ECO Fan Unit Binding Mode

Where a CO2 sensor is present, it must first be bound to the fan unit

before it can work. In order to bind the sensor(s) the fan must be in

binding mode. The steps required to enter binding mode are shown

below.

•Ensure the fan unit is powered on.

•Unit will enter the start-up sequence for 2 minutes when first

powered on. Press the down button on the ceiling diffuser control

panel once, to exit the start-up sequence.

•Press and hold the both the UP and DOWN buttons for 20-30

seconds then release. A single horizontal bar on the display flashes.

•Press "down" to enter binding mode (binding mode lasts for 5

minutes).The unit will now display a flashing ‘b’ to indicate it has

entered binding mode.

Solid “P” indicates boost, flashing “b” indicates binding mode.

2.3 Binding Sensor To DRI-ECO Fan Unit

Putting the unit into binding (Section 2.2) before powering the sensors

will automatically bind the sensors to the unit. However if they do not

bind follow the below steps.

•Put the unit into binding mode.

•Power up sensors (insert batteries for humidity, mains for CO2).

•Tap indented button then hold until left hand LED flashes red/

green (ignore red/blue and continue to hold). Release button

whilst flashing.

•Tap indented button again, whilst red/green LED is still flashing.

•Close binding window on fan control panel by holding both “up”

and “down” for 5 seconds and release.

•Check sensor has bound by tapping indented button and look for

left hand LED to go green. If it displays red, repeat from step 1.

3.0 CONTROLS

3.1 Setting Sensor Setpoint

The sensors will automatically trigger the fan to increase speed once

the sensor set point has been exceeded. To change the sensor set point,

press and hold the indent button until the status indication LED flashes

BLUE/RED then release, the green LED’s illuminate to show the current

sensor set point. Press the button to cycle through all allowed values,

and press and hold to confirm choice. If the button is not operated for

10 seconds the set point currently selected is stored.

Boost (Sensor) - If a sensor set point has been exceeded, the fan speed

will increase to maximum and a solid ‘b’ will be shown in the display.

3.2 LED Indicators

The sensors and switches include an LED which illuminates when a

button is pressed. A green light shows that communication between

the sensor or switch and the fan unit is taking place. A red light shows

that no communication is taking place and binding may be required.

4.0 MAINTENANCE

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

4.1 Routine Maintenance

This sensor can be cleaned with a dry brush or dry cloth. Any other

maintenance or cleaning should be carried out by properly qualified

personnel.

Ensure the unit does not come into contact with any kind of liquid

or solvent. If this should occur, contact a qualified technician before

reassembling the fan.