16. 04. 21. Document Number 671635 1

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

ESCO-CO2D

Ecosmart Connect Duct Mounted CO2Sensor

Installation Manual

1.0 SAFETY INFORMATION

• The provision of the electrical supply and the connection of the unit to the mains must be

carried out by a qualified electrician.

1.1 Hazard Symbols

GENERAL WARNING

Signifies a general warning regarding hazard specified by supplementary information.

REFER TO INSTRUCTION MANUAL

Read and understand the installation and maintenance manual before installing,

operating or maintaining this product.

1.2 Important Information

This manual contains important information on the safe and

appropriate assembly, transport, commissioning, operation,

maintenance, disassembly and simple troubleshooting of the product.

While the product has been manufactured according to the accepted

rules of current technology, there is still a danger of personal injury or

damage to equipment if the following general safety instructions and

the warnings contained in these instructions are not complied with.

•Read these instructions completely and thoroughly before

working with the product.

•Keep these instructions in a location where they are accessible

to all users at all times.

•Always include the operating instructions when you pass the

product on to third parties.

1.3 Personal Protective Equipment

The following minimum Personal Protective Equipment (PPE) is

recommended when interacting with Nuaire product:

•Protective Steel Toed Shoes - when handling heavy objects.

•Full Finger Gloves (Marigold PU800 or equivalent) - when

handling sheet metal components.

•Semi Fingerless Gloves (Marigold PU3000 3DO or equivalent)

- when conducting light work on the unit requiring tactile

dexterity.

•Safety Glasses - when conducting any cleaning/cutting operation

or exchanging filters.

•Reusable Half Mask Respirators - when replacing filters which

have been in contact with normal room or environmental air.

Nuaire would always recommend a site specific risk assessment by a

competent person to determine if any additional PPE is required.

2.0 INTRODUCTION

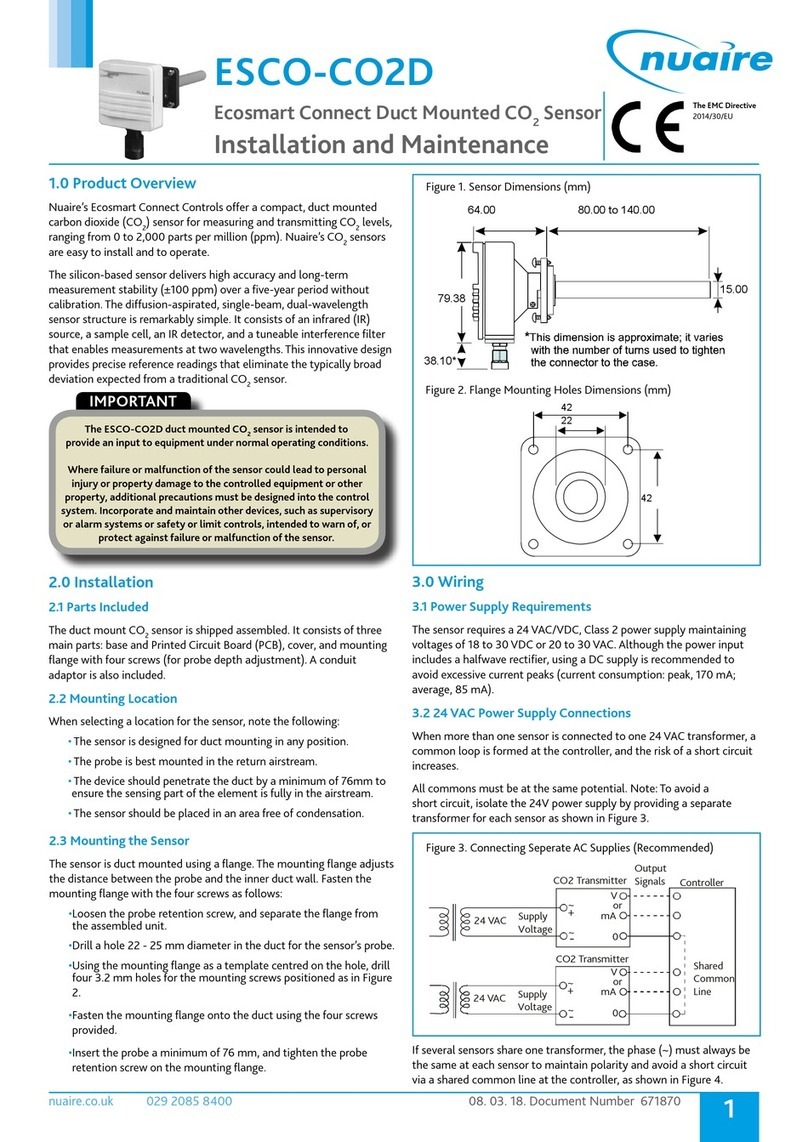

Nuaire’s Ecosmart Connect Controls offer a compact, duct mounted

carbon dioxide (CO2) sensor for measuring and transmitting CO2levels,

ranging from 0 to 2,000 parts per million (ppm). Nuaire’s CO2sensors

are easy to install and to operate.

The silicon-based sensor delivers high accuracy and long-term

measurement stability (±100 ppm) over a five-year period without

calibration. The diffusion-aspirated, single-beam, dual-wavelength

sensor structure is remarkably simple. It consists of an infrared (IR)

source, a sample cell, an IR detector, and a tuneable interference filter

that enables measurements at two wavelengths. This innovative design

provides precise reference readings that eliminate the typically broad

deviation expected from a traditional CO2sensor.

The ESCO-CO2D duct mounted CO2sensor is intended to

provide an input to equipment under normal operating conditions.

Where failure or malfunction of the sensor could lead to personal injury or

property damage to the controlled equipment or other

property, additional precautions must be designed into the control system.

Incorporate and maintain other devices, such as supervisory or alarm

systems or safety or limit controls, intended to warn of, or protect against

failure or malfunction of the sensor.

2.1 MECHANICAL INSTALLATION

2.2 Parts Included

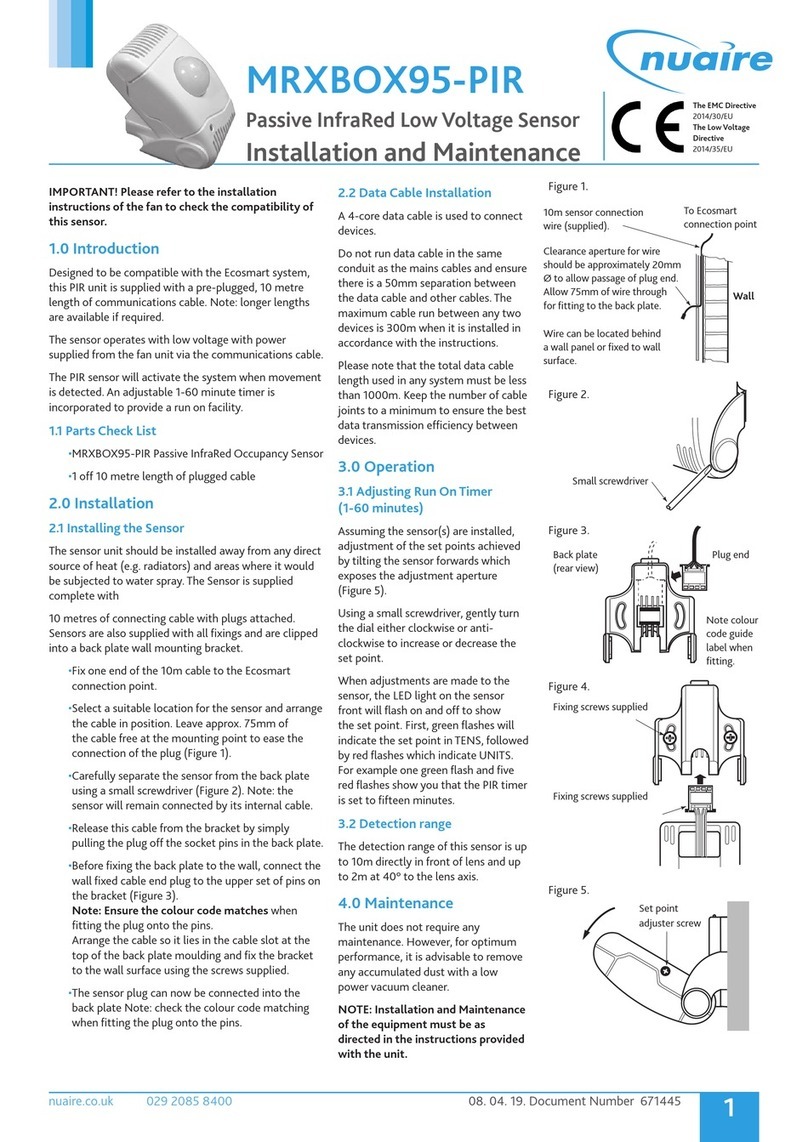

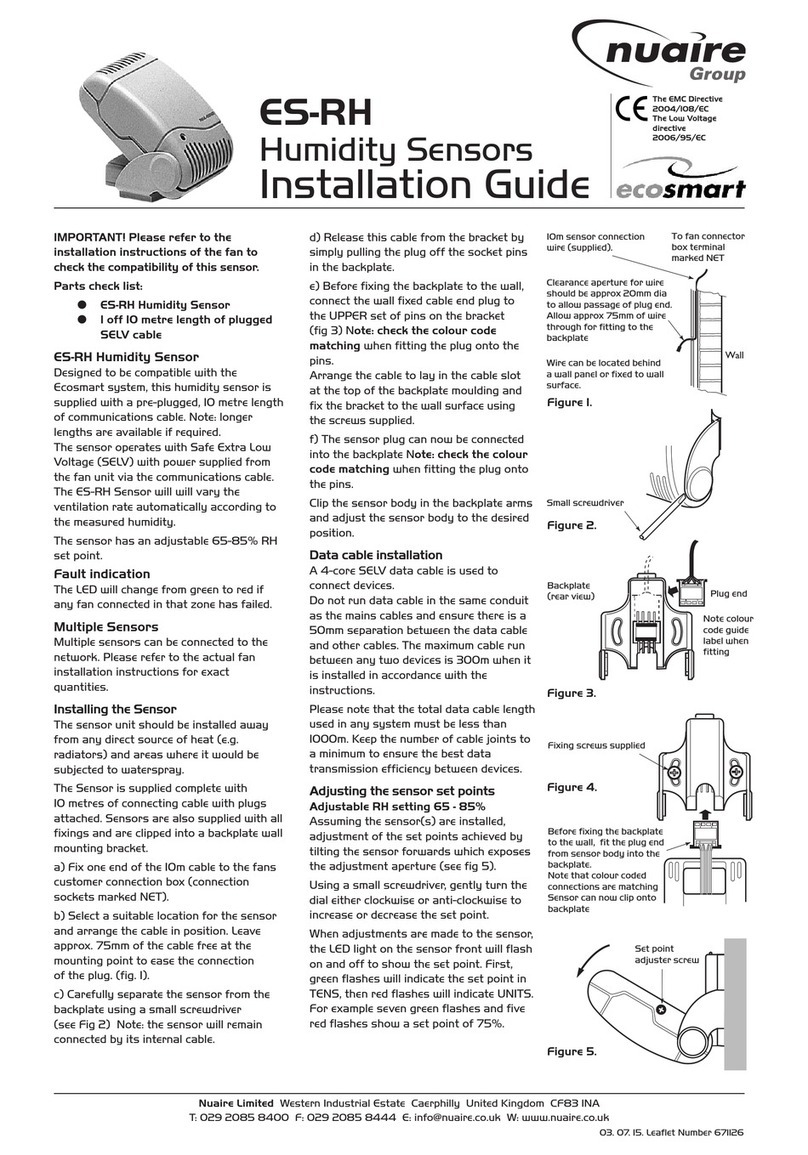

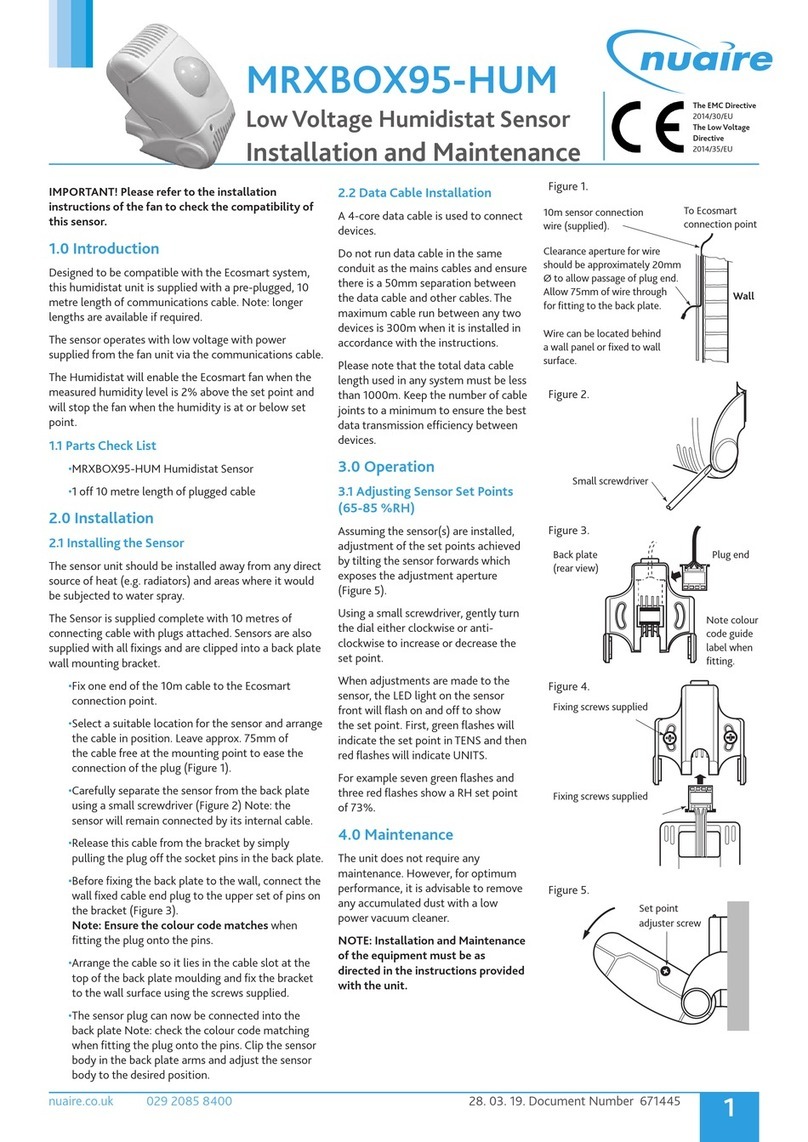

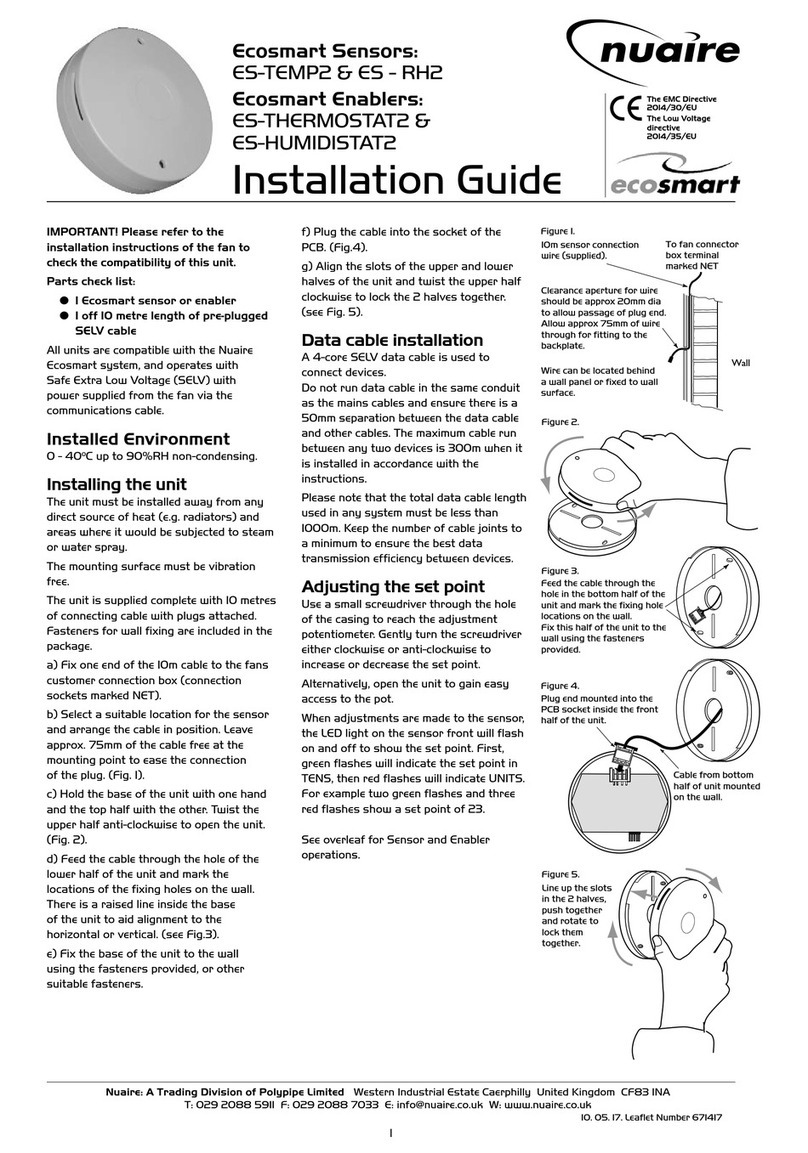

The duct mount CO2sensor is shipped assembled. It consists of three

main parts: base and Printed Circuit Board (PCB), cover, and mounting

flange with four screws (for probe depth adjustment). A conduit

adaptor is also included.

2.3 Mounting Location

When selecting a location for the sensor, note the following:

•The sensor is designed for duct mounting in any position.

•The probe is best mounted in the return air stream.

•The device should penetrate the duct by a minimum of 76mm to

ensure the sensing part of the element is fully in the air stream.

•The sensor should be placed in an area free of condensation.