1

nuaire.co.uk 029 2085 8400 08. 03. 18. Document Number 671870

The EMC Directive

2014/30/EU

ESCO-CO2D

Ecosmart Connect Duct Mounted CO2Sensor

Installation and Maintenance

1.0 Product Overview

Nuaire’s Ecosmart Connect Controls offer a compact, duct mounted

carbon dioxide (CO2) sensor for measuring and transmitting CO2levels,

ranging from 0 to 2,000 parts per million (ppm). Nuaire’s CO2sensors

are easy to install and to operate.

The silicon-based sensor delivers high accuracy and long-term

measurement stability (±100 ppm) over a five-year period without

calibration. The diffusion-aspirated, single-beam, dual-wavelength

sensor structure is remarkably simple. It consists of an infrared (IR)

source, a sample cell, an IR detector, and a tuneable interference filter

that enables measurements at two wavelengths. This innovative design

provides precise reference readings that eliminate the typically broad

deviation expected from a traditional CO2sensor.

2.0 Installation

2.1 Parts Included

The duct mount CO2sensor is shipped assembled. It consists of three

main parts: base and Printed Circuit Board (PCB), cover, and mounting

flange with four screws (for probe depth adjustment). A conduit

adaptor is also included.

2.2 Mounting Location

When selecting a location for the sensor, note the following:

•The sensor is designed for duct mounting in any position.

•The probe is best mounted in the return airstream.

•The device should penetrate the duct by a minimum of 76mm to

ensure the sensing part of the element is fully in the airstream.

•The sensor should be placed in an area free of condensation.

IMPORTANT

The ESCO-CO2D duct mounted CO2sensor is intended to

provide an input to equipment under normal operating conditions.

Where failure or malfunction of the sensor could lead to personal

injury or property damage to the controlled equipment or other

property, additional precautions must be designed into the control

system. Incorporate and maintain other devices, such as supervisory

or alarm systems or safety or limit controls, intended to warn of, or

protect against failure or malfunction of the sensor.

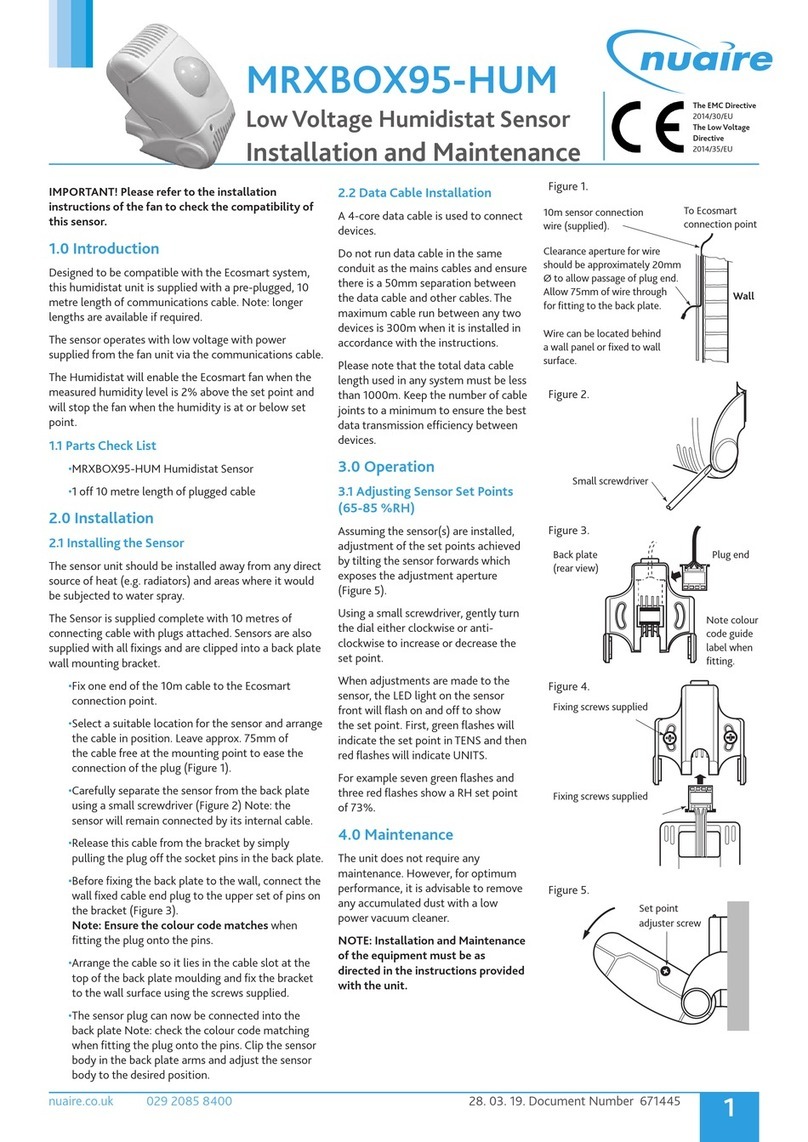

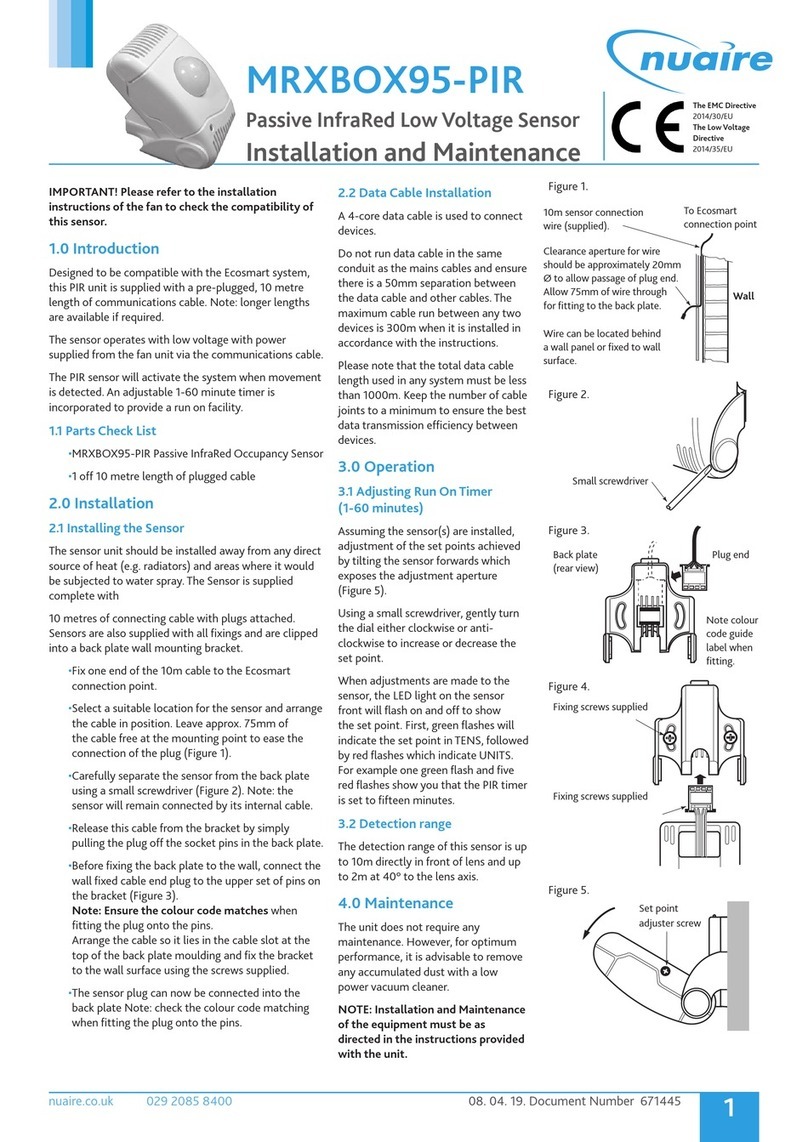

15.00

80.00 to 140.00

38.10*

64.00

79.38

Figure 1. Sensor Dimensions (mm)

2.3 Mounting the Sensor

The sensor is duct mounted using a flange. The mounting flange adjusts

the distance between the probe and the inner duct wall. Fasten the

mounting flange with the four screws as follows:

•Loosen the probe retention screw, and separate the flange from

the assembled unit.

•Drill a hole 22 - 25 mm diameter in the duct for the sensor’s probe.

•Using the mounting flange as a template centred on the hole, drill

four 3.2 mm holes for the mounting screws positioned as in Figure

2.

•Fasten the mounting flange onto the duct using the four screws

provided.

•Insert the probe a minimum of 76 mm, and tighten the probe

retention screw on the mounting flange.

3.0 Wiring

3.1 Power Supply Requirements

The sensor requires a 24 VAC/VDC, Class 2 power supply maintaining

voltages of 18 to 30 VDC or 20 to 30 VAC. Although the power input

includes a halfwave rectifier, using a DC supply is recommended to

avoid excessive current peaks (current consumption: peak, 170 mA;

average, 85 mA).

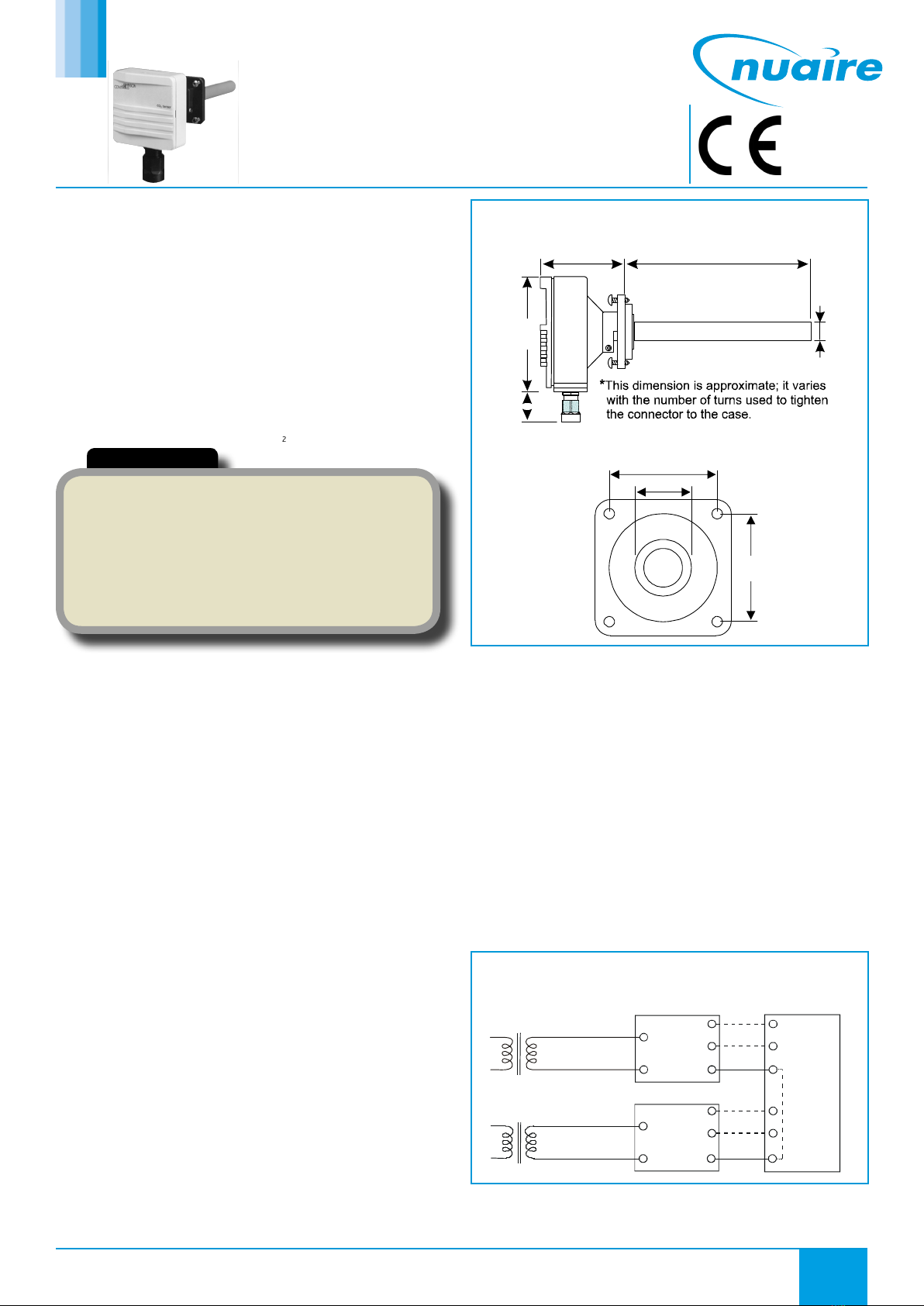

3.2 24 VAC Power Supply Connections

When more than one sensor is connected to one 24 VAC transformer, a

common loop is formed at the controller, and the risk of a short circuit

increases.

All commons must be at the same potential. Note: To avoid a

short circuit, isolate the 24V power supply by providing a separate

transformer for each sensor as shown in Figure 3.

~

+

~

-

0

~

+

~

-

Shared

Common

Line

24 VAC Supply

Voltage

CO2 Transmitter

24 VAC Supply

Voltage

Output

Signals

CO2 Transmitter Controller

V

0

mA

or

V

mA

or

Figure 3. Connecting Seperate AC Supplies (Recommended)

If several sensors share one transformer, the phase (~) must always be

the same at each sensor to maintain polarity and avoid a short circuit

via a shared common line at the controller, as shown in Figure 4.

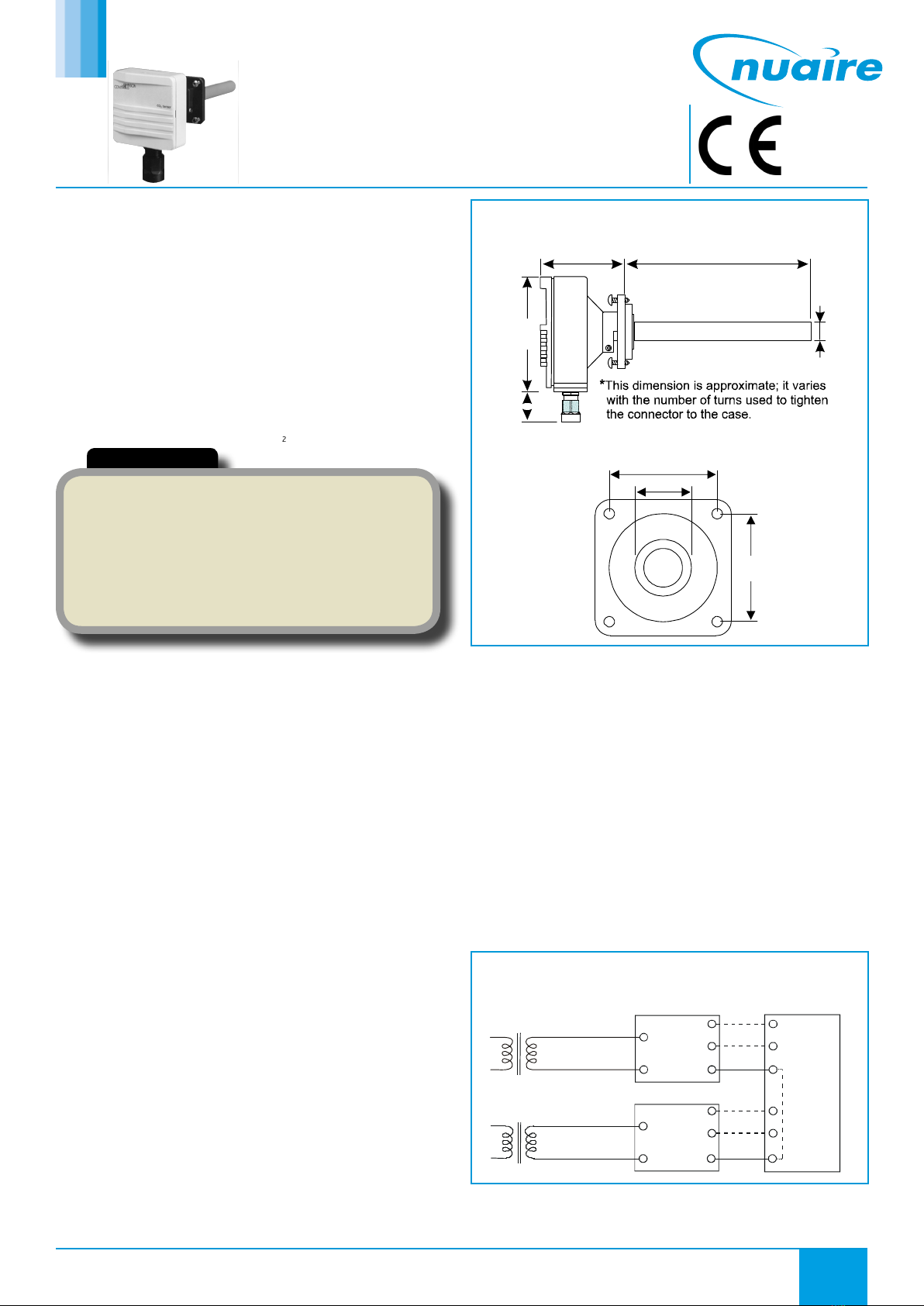

42

22

42

Figure 2. Flange Mounting Holes Dimensions (mm)