2

Operating Instructions and Parts Manual 24815

SANDBLAST BENCH TOP CABINET

5/19

2019 OEMTOOLS™

Thank you for purchasing this OEM Shot Blast Cabinet

which is designed for professional, workshop use.

LIMITED 90 DAY WARRANTY

If within 90 days from date of purchase, this product fails due to

a defect in materials or workmanship, return the product

with proof of purchase, prepaid, to OEM Warranty Dept., 3580

E. Raines Rd. #3, Memphis, TN 38118, for repair or replace-

ment with an item of equal or greater value. This warranty

excludes incidental/consequential damages and failures due to

misuse, abuse or normal wear and tear. This warranty gives you

specific legal rights, and you may also have other rights, which

vary, from state to state. OEM will not be responsible for any

consequential or incidental damages arising from the breach

of this or any other warranty, whether expressed, implied or

statutory. Some states do not allow the exclusion or limitation

of consequential or incidental damages, so the above exclusion

may not apply to you. This warranty gives you specific legal

rights, and you may also have other rights which vary from

state to state.

ALWAYS WEAR SAFETY GOGGLES.

CONTENTS Page

Spare Parts & Service Contents ............................... 1

Features .................................................................... 2

Safety Precautions .................................................... 2

Assembly................................................................... 3

Changing Nozzles .................................................... 4

Operation .................................................................. 4

Maintenance ............................................................. 5

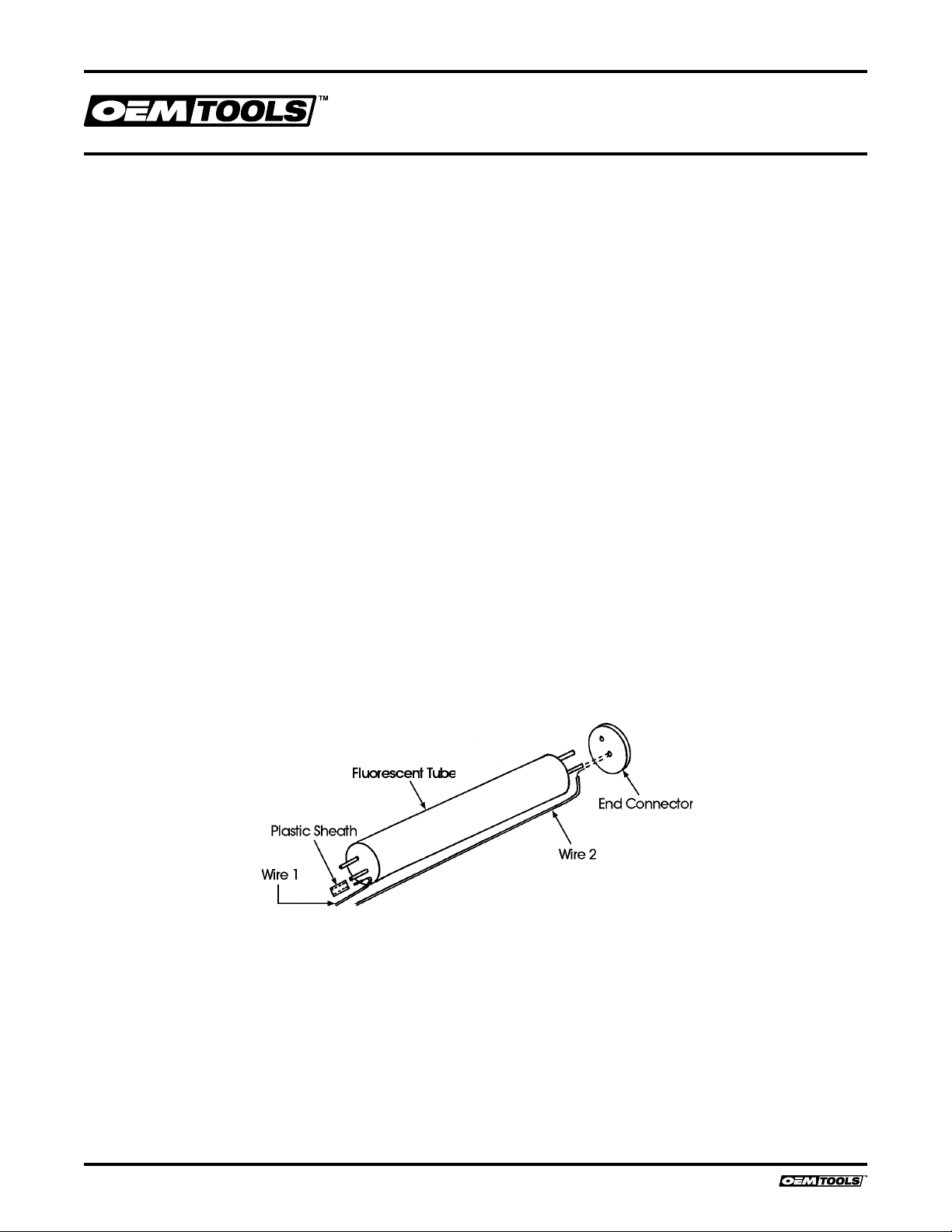

Changing the Fluorescent Tube ............................... 5

Parts Diagrams ......................................................... 6

Parts List .................................................................. 7

Troubleshooting ........................................................ 8

FEATURES

The 3 cu. ft. cabinet is lit by a low voltage (12 volt)

fluorescent tube. A transformer is provided which

should be plugged directly into the main supply. The

attached cable is then plugged into the switch box,

mounted on the left side of the cabinet. The switch box

contains the ON/OFF rocker switch.

We strongly recommend that this unit be used with a

vacuum extraction device. Air is extracted via a double

filtration system from the facility at the right hand side

of the cabinet.

Please note that when vacuum extraction is used,

air will be drawn into the cabinet through the hole on

the back panel of the unit. The hole is covered on the

outside with a filter plate, and housed within the plate

is a foam filter, which must always be in place. This

is to prevent grit from being blown out, if/when the

vacuum extraction is NOT used.

The lid is provided with a double clear plastic window,

the inner of which may be renewed quickly and easily if it

should become damaged by the sand blasting action.

A variety of abrasive nozzles is supplied with the unit

to produce a useful range of power and grit densities

to satisfy all requirements. The cabinet is designed

for use with dry abrasives ONLY. We recommend

Aluminium Oxide (for cleaning steel) and Glass Beads

(for cleaning Aluminium).

It is necessary to provide a clean, dry air supply,

capable of delivering a minimum of 10 cu. ft./min at

100 PSI. Please consult your air compressor manual,

ensuring you comply with all safety precautions

regarding the use of air compressors, and observe all

necessary precautions when using compressed air.

SAFETY PRECAUTIONS

• Ensure you comply with all precautions concerning

the use of air compressors and compressed air.

• Ensure all air connections are secure.

• Do Not use the machine if the rubber gloves are

ripped or otherwise unserviceable.

• Ensure the clear plastic lid is firmly secured before

pressing the trigger.

• Keep the jet well away from the air inlet hose (from

side panel to gun).

• ALWAYS wear safety glasses. (Normal eye glasses

are NOT safety glasses).

WARNING:This product can expose you to

chemicals, including DEHP and lead, which are

known to the State of California to cause cancer and

birth defects or other reproductive harm. For more

information, go to www.P65Warnings.ca.gov.