ENGLISH

CHAPTER................................................. 1

Chapter for the technician and operator

1.1 GENERAL WARNINGS ..................................... Page GB-3

1.2 REFERENCE NORMATIVE...............................Page GB-4

1.3 DESCRIPTION OF THE SYMBOLS .................. Page GB-4

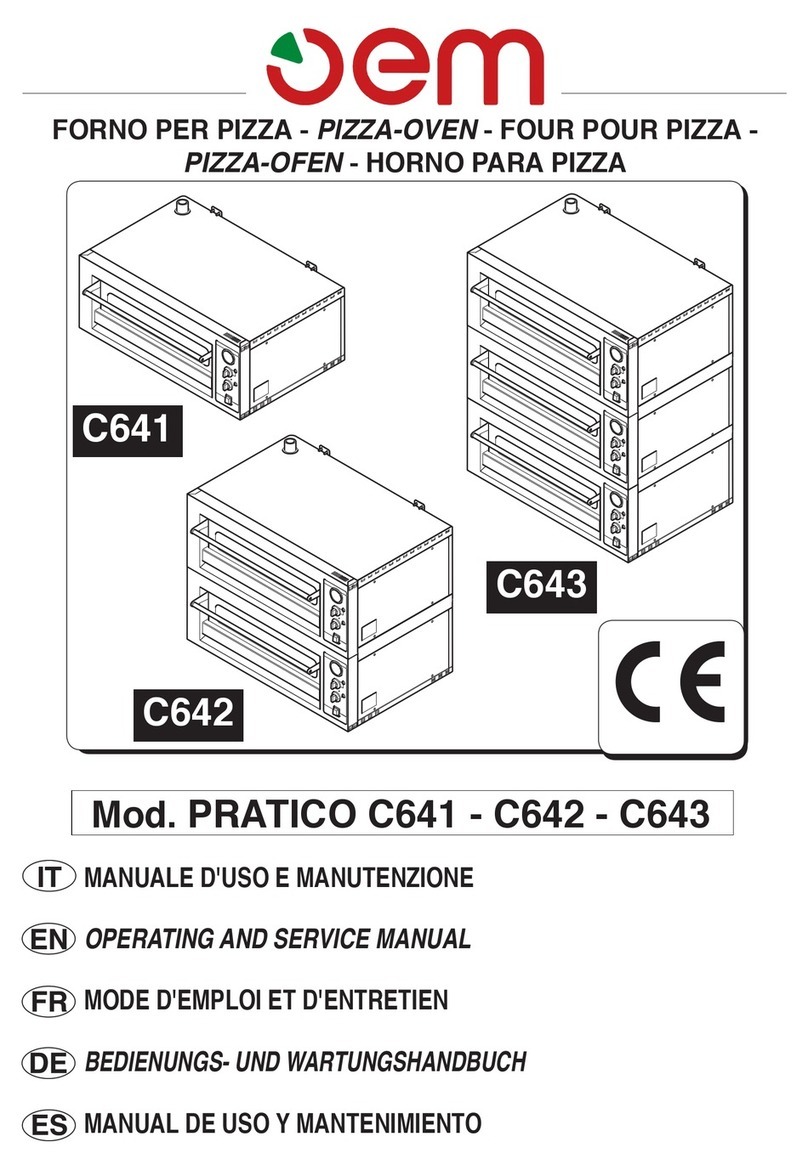

1.4 OVEN COMPOSITION ...................................... Page GB-4

1.5 PREARRANGEMENTS AT PURCHASER’S

CHARGE............................................................Page GB-5

1.6 EMERGENCY OPERATIONS IN CASE

OF FIRE.............................................................Page GB-5

1.7 EXPLOSION RISK.............................................Page GB-5

1.8 ACOUSTIC PRESSURE LEVEL ....................... Page GB-5

CHAPTER................................................. 2

Chapter for the technician

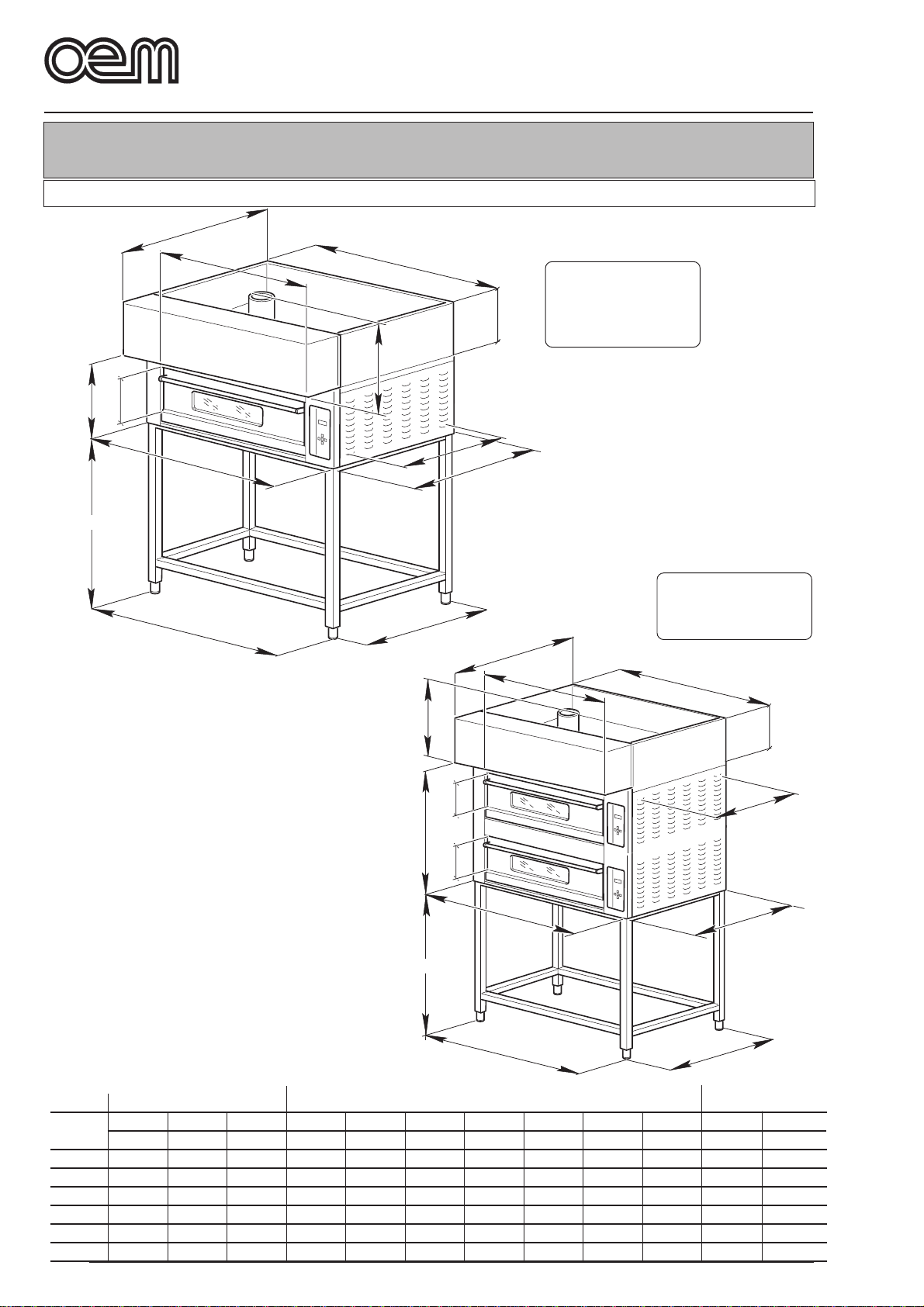

-OVERALL DIMENSIONS........................................ Page GB-6

2.1

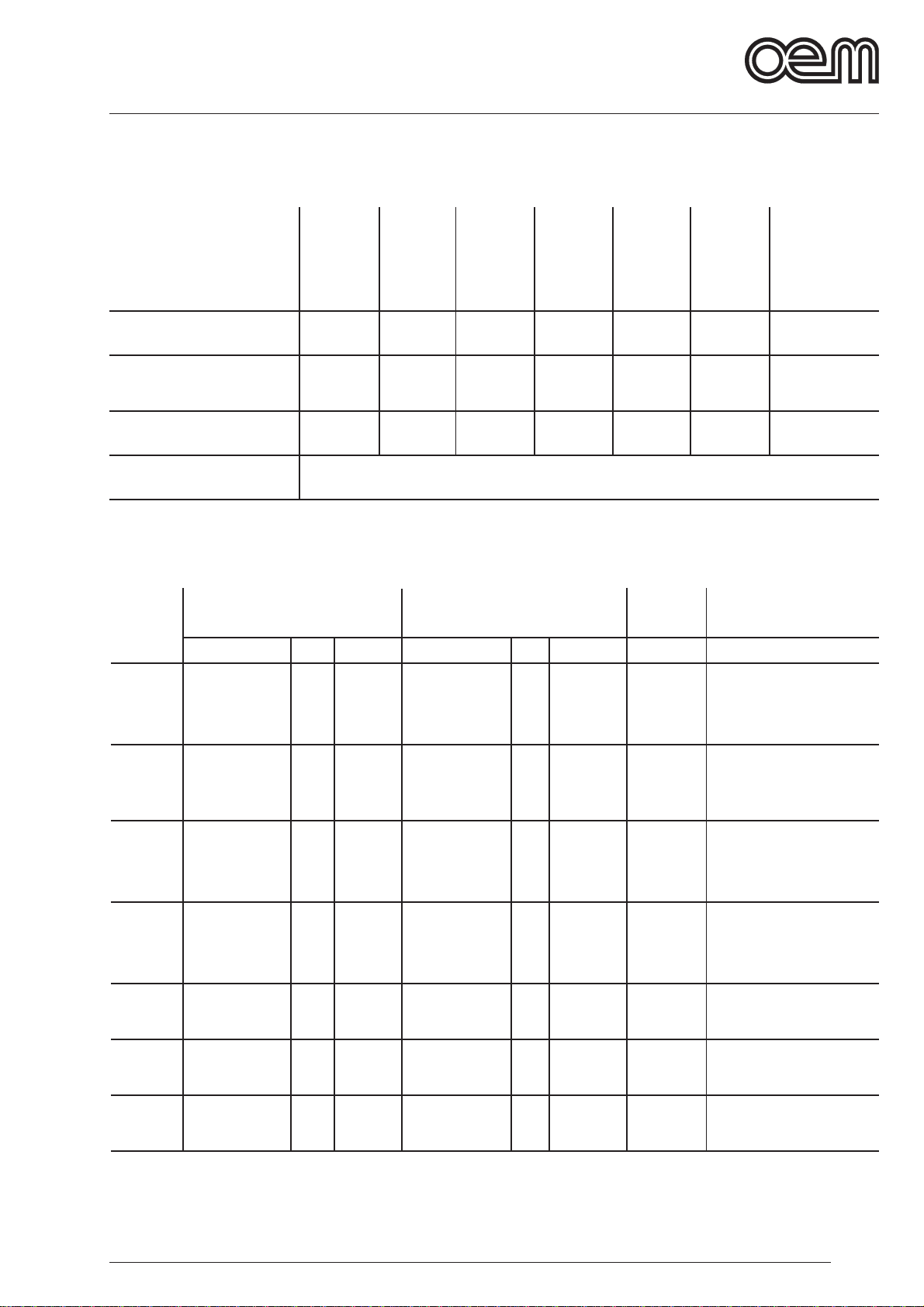

TECHNICAL FEATURES

................................. Page GB-7

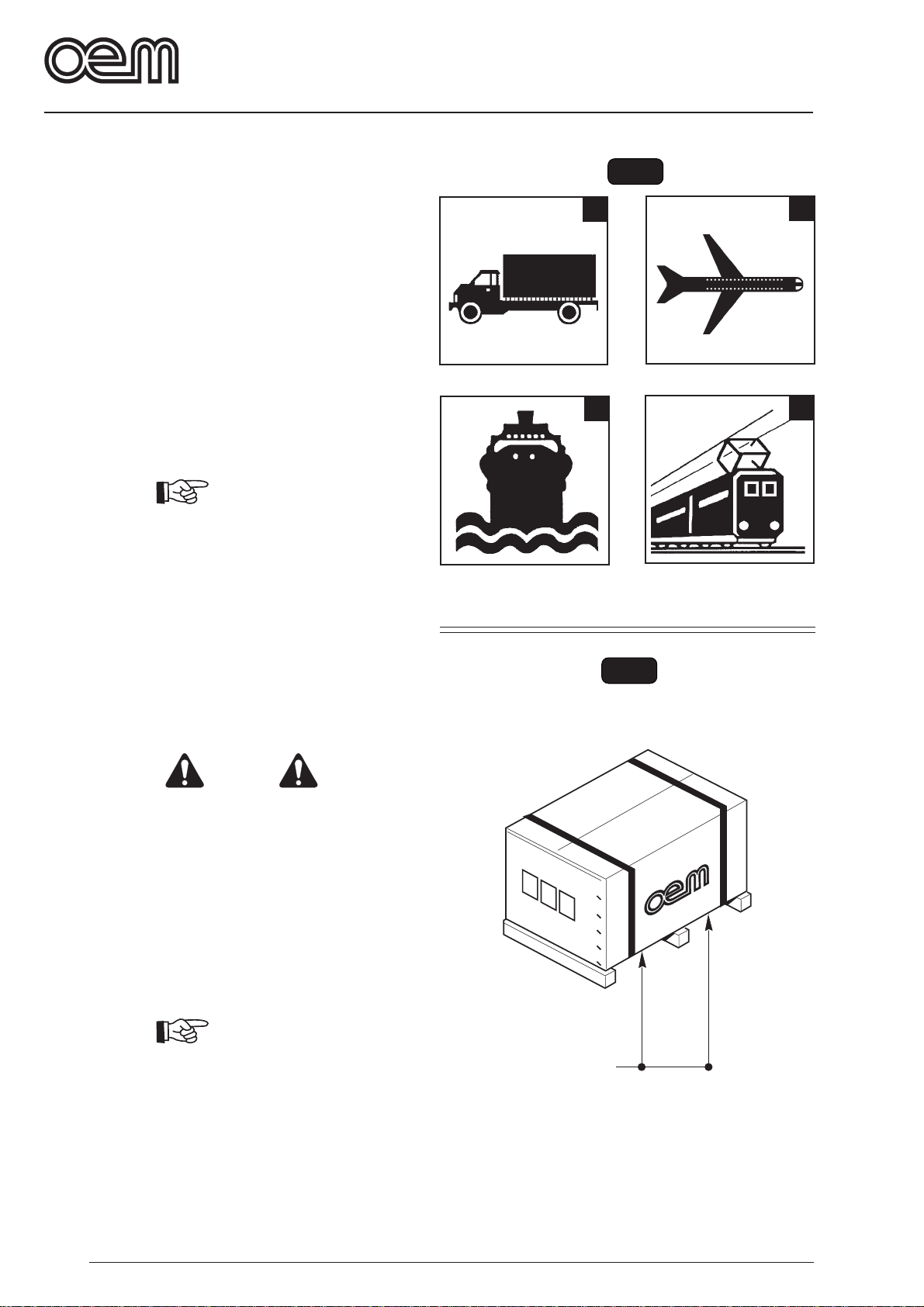

2.2 TRANSPORT..................................................... Page GB-8

2.2.a Shipment...................................................Page GB-8

2.2.b Lifting of the packing................................. Page GB-8

2.2.c Storage ..................................................... Page GB-8

2.3 RECEPTION OF THE MACHINE ...................... Page GB-9

2.4 UNPACKING ......................................................Page GB-9

2.5 IDENTIFICATION OF THE COMPONENTS ....Page GB-10

2.6 OVEN IDENTIFICATION................................. Page GB-10

CHAPTER................................................. 3

Chapter for the technician

3.1 OVEN LIFTING ................................................ Page GB-11

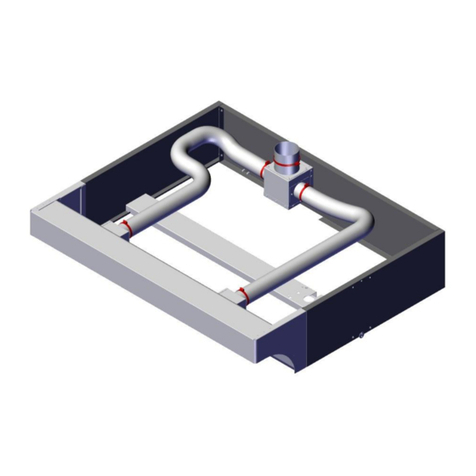

3.2 ASSEMBLING OF THE COMPONENTS.........Page GB-11

3.3 ELECTRICAL CONNECTION..........................Page GB-13

3.3.a Electric oven connection ......................... Page GB-13

3.3.b Electric hood connection ........................ Page GB-14

3.3.c Unipotential connection...........................Page GB-14

3.4 OVEN POSITIONING ......................................Page GB-14

3.4.a Chimney connection ............................... Page GB-14

3.5 FIRST STARTING ............................................Page GB-14

CHAPTER................................................. 4

Chapter for the technician and operator

4.1 TYPE OF USE AND CONTRAINDICATIONS.. Page GB-15

4.2 SAFETY PLATES.............................................Page GB-15

4.3 SAFETY DEVICES .......................................... Page GB-16

4.4 USER’S AREAS...............................................Page GB-16

4.5 RESIDUAL DANGER AREAS.......................... Page GB-16

CHAPTER................................................. 5

Chapter for the technician and operator

5.1 CONTROL BOARD AND PILOT LIGHTS ON

DIGITALLY CONTROLLED OVENS................. Page GB-17

5.2 MANUAL OVEN CONTROL BOARD...............Page GB-18

5.3 OVEN PREPARATION ..................................... Page GB-19

5.3.a General rules to bake on refractory

surfaces ..................................................Page GB-19

5.3.b General rules to bake in baking-tin ......... Page GB-19

5.3.c Oven starting .......................................... Page GB-20

5.4 PIZZA BAKING ................................................ Page GB-21

5.5 ALARM CONDITIONS DURING OVEN

FUNCTIONING ................................................Page GB-21

5.5.a ATemperature feeler alarm is damaged or

disconnected ................................................... Page GB-21

5.6 SELF-CLEANING CYCLE ............................... Page GB-22

5.7 CUTTING OFF.................................................Page GB-22

5.8 MALFUCTIONING,CAUSE AND CURE ..........Page GB-23

5.9 SAFETY THERMOSTAT RECHARGE............. Page GB-23

CHAPTER................................................. 6

Chapter for the technician and operator

6.1 ROUTINE AND PLANNED MAINTENANCE ...Page GB-24

6.1.a In general ...............................................Page GB-24

6.1.b Ordinary maintenance ........................... Page GB-24

6.1.b - a Outer cleaning

(to be carried out every day) ........................... Page GB-24

6.1.b - b Fireproof surface cleaning (to be

carried out every day) ..................................... Page GB-24

6.1.c Planned maintenance ............................Page GB-25

6.1.c - a Every 600 hours a careful

chamber cleaning .............................Page GB-25

6.1.c - b Every 2 years.................................... Page GB-25

6.1.d Maintenance in case of need.................Page GB-25

6.1.d - a Lamp holder replacement.................Page GB-25

6.1.d - b Lamp replacement............................Page GB-26

6.1.d - c Ceiling or bedplate resistance

replacement...................................... Page GB-26

6.1.d - d Door spring replacement .................. Page GB-27

6.1.d - e Door pane replacement .................... Page GB-28

CHAPTER................................................. 7

Chapter for the technician

7.1 OVEN DISASSEMBLY .................................... Page GB-29

7.2 OVEN SCRAPPING ........................................ Page GB-29

7.3 DISPOSING OF HARMFUL SUBSTANCES.... Page GB-29

WIRING DIAGRAM MM/D-E 435 - V400-230

Three-phase/V230 Single-phase ................... Page. GB-30

WIRING DIAGRAM MB/D-E 835 - V400 ............... Page. GB-31

WIRING DIAGRAM MB/D-E 835 - 230V

Three-phase ................................................... Page. GB-32

WIRING DIAGRAM MM/MB/E-D - 635S/L - 935 -

1235S/L - 230V Three-phase ......................... Page. GB-33

SCHEMA WIRING DIAGRAM MM/MB/E-D - 635S/L - 935 -

1235S/L - 400V .............................................. Page. GB-34

OVEN CAPTION MM435 E/D .............................. Page. GB-35

OVEN CAPTION MB 835 E/D ............................... Page. GB-35

OVEN CAPTION MM.E.D.-635S-635L-935 +

MB.E.D.-1235S-1235L ................................... Page. GB-35