TOC-4

General Wiring Diagram ........................................................................................................................... 4-1

Engine....................................................................................................................................................... 4-2

Wiring Diagram between Parts........................................................................................................... 4-3

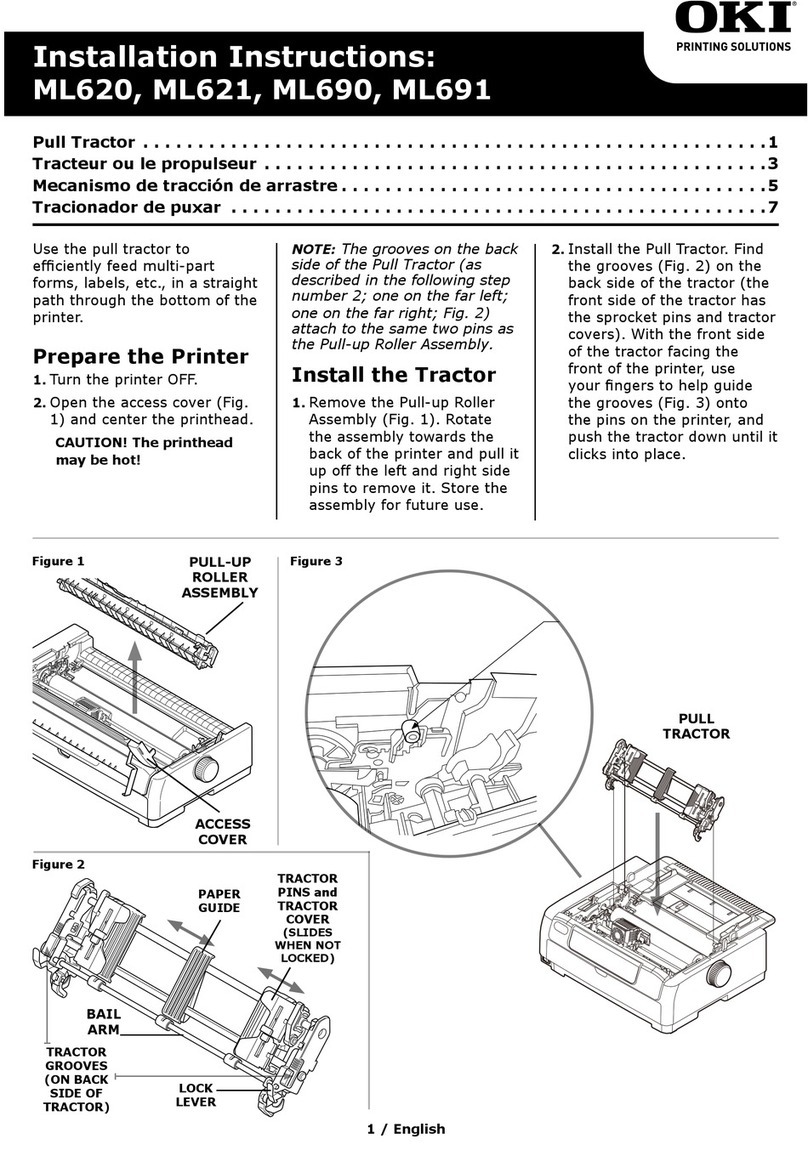

Configuration................................................................................................................................ 4-3

Notes on Using the Wiring Diagram between Parts..................................................................... 4-4

1 Power supply................................................................................................................................... 4-6

2 Fuser............................................................................................................................................... 4-7

3 Paper Feed...................................................................................................................................... 4-8

4 Xero / Deve ..................................................................................................................................... 4-9

5 Drive / CRUM ................................................................................................................................ 4-11

6 Tray1 ............................................................................................................................................. 4-13

7 Tray2 ............................................................................................................................................. 4-14

8 MPF............................................................................................................................................... 4-16

9 ROS............................................................................................................................................... 4-19

10 Exit .............................................................................................................................................. 4-19

11 Controller..................................................................................................................................... 4-21

1000 Sheet Feeder................................................................................................................................. 4-22

General Wiring Diagram................................................................................................................... 4-22

Wiring Diagram between Parts......................................................................................................... 4-22

Configuration.............................................................................................................................. 4-22

Notes on Using the Wiring Diagram between Parts................................................................... 4-23

1 Drive.............................................................................................................................................. 4-24

2 Tray3 ............................................................................................................................................. 4-26

3 Tray4 ............................................................................................................................................. 4-28

Duplex..................................................................................................................................................... 4-30

General Wiring Diagram................................................................................................................... 4-30

Wiring Diagram between Parts......................................................................................................... 4-32

Configuration.............................................................................................................................. 4-32

Notes on Using the Wiring Diagram between Parts................................................................... 4-32

1 Duplex ........................................................................................................................................... 4-33

Exit.......................................................................................................................................................... 4-35

General Wiring Diagram................................................................................................................... 4-35

Wiring Diagram between Parts......................................................................................................... 4-36

Configuration.............................................................................................................................. 4-36

Notes on Using the Wiring Diagram between Parts................................................................... 4-37

1 Motor / Solenoid ............................................................................................................................ 4-38

2 Sensor / Fan.................................................................................................................................. 4-39

Finisher................................................................................................................................................... 4-41

General Wiring Diagram................................................................................................................... 4-41

Configuration.............................................................................................................................. 4-42

Notes on Using the Wiring Diagram between Parts................................................................... 4-44

1 Power Supply ................................................................................................................................ 4-46

2 H-Transport ................................................................................................................................... 4-47

3 Sensor (Paper feed section).......................................................................................................... 4-48

4 Sensor (Exit section) ..................................................................................................................... 4-50

5 Motor............................................................................................................................................. 4-51

6 Motor / Clutch / Solenoid............................................................................................................... 4-52

7 Tamper.......................................................................................................................................... 4-54

8 Stapler........................................................................................................................................... 4-55

9 Puncher1....................................................................................................................................... 4-56

10 Puncher2..................................................................................................................................... 4-57

HCF......................................................................................................................................................... 4-59

General Wiring Diagram ......................................................................................................................... 4-59

Wiring Diagram between Parts......................................................................................................... 4-60

Configuration.............................................................................................................................. 4-60