41154001TH Rev.2 4 /

Contents

1. CONFIGURATION ............................................................................................. 77

1.1 System Configuration ..................................................................................... 7

1.2 Printer Configuration ...................................................................................... 9

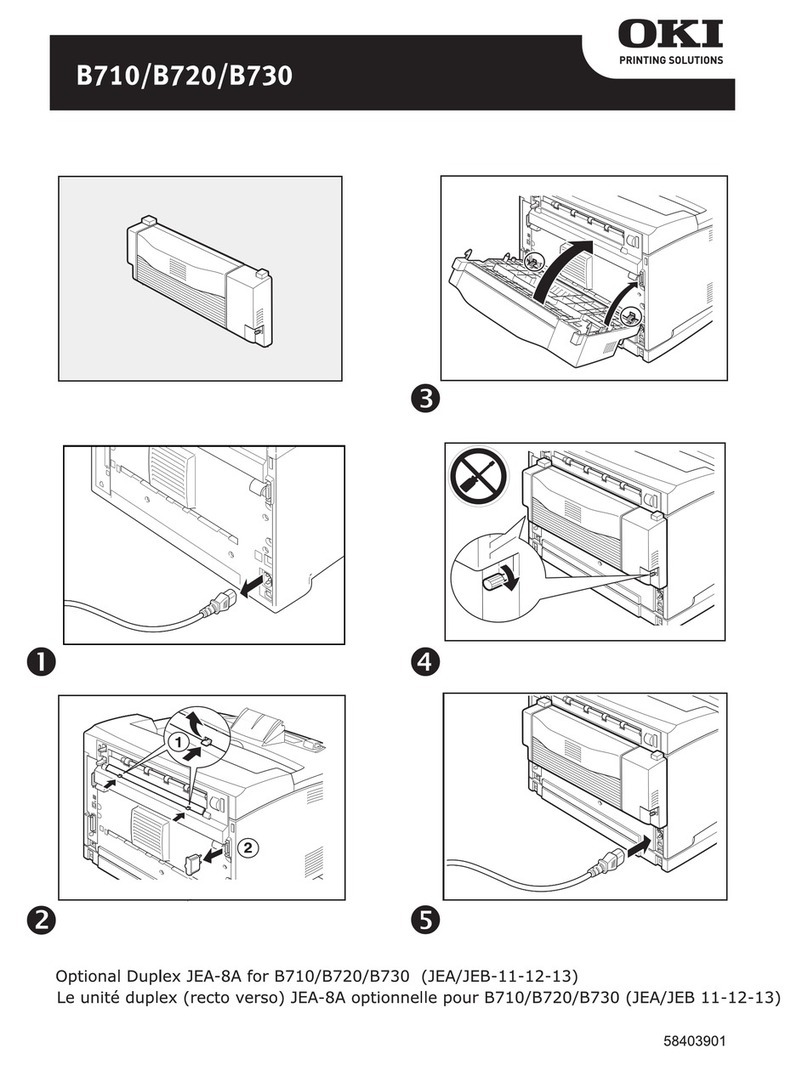

1.3 Optional Configuration.................................................................................. 10

1.4 Specification ................................................................................................. 12

1.5 Safety Standards.......................................................................................... 14

1.5.1Certification Label ...................................................................................................... 14

1.5.2Warning Label............................................................................................................ 14

1.5.3Warning/Caution Marking .......................................................................................... 15

2. OPERATION DESCRIPTION............................................................................. 16

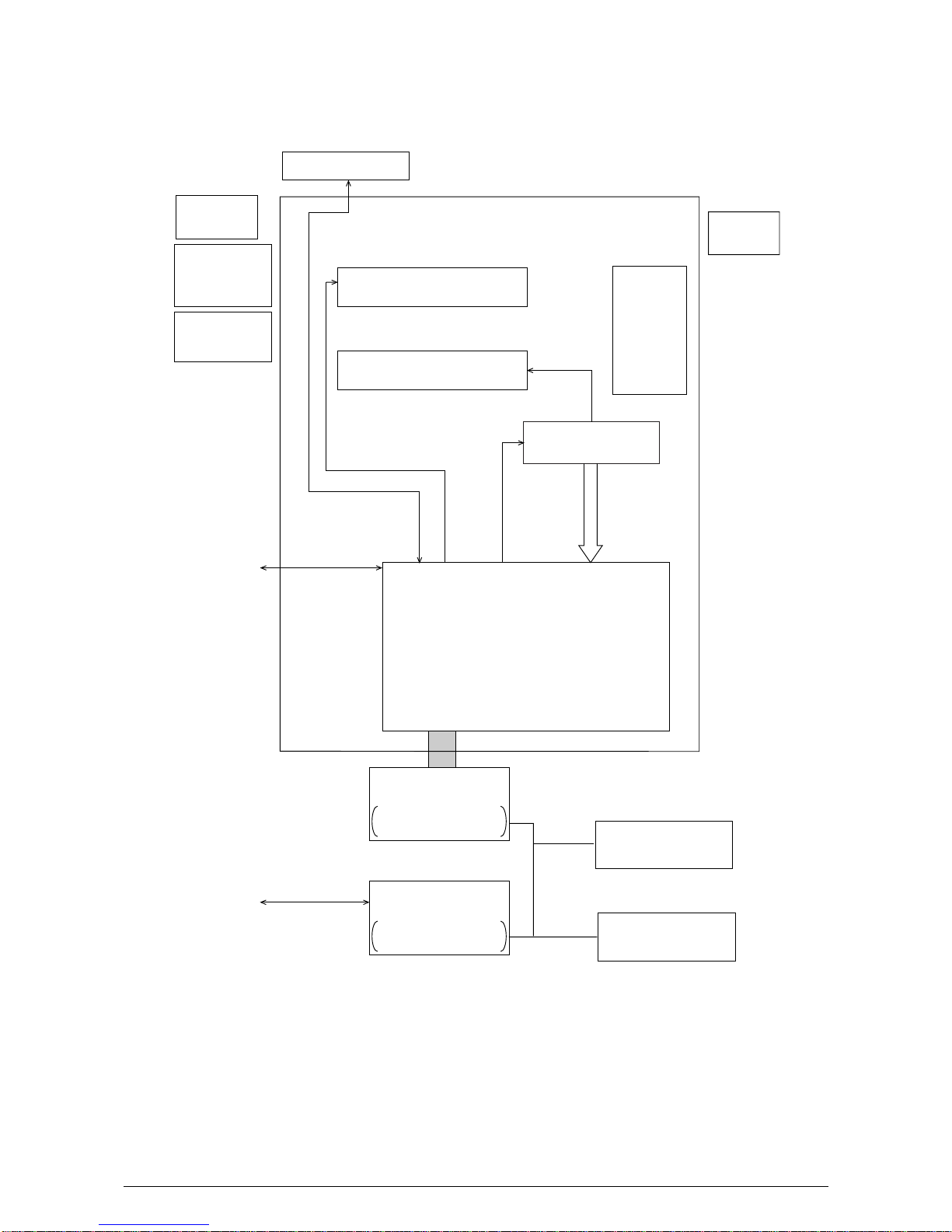

2.1 Main Control Board ...................................................................................... 18

2.2 Power Supply/Sensor Board ........................................................................ 19

2.3 Electrophotographic Process ....................................................................... 21

2.3.1 Electrophotographic Process Mechanism ................................................................ 21

2.3.2 Electrophotographic Process .................................................................................... 24

2.3.3 Process Operation Descriptions ............................................................................... 27

2.4 Paper Jam Detection .................................................................................... 37

2.5 Cover Open .................................................................................................. 39

2.6 Toner Low Detection..................................................................................... 40

3. PARTS REPLACEMENT.................................................................................... 42

3.1 Precautions for Parts Replacement.............................................................. 42

3.2 Parts Layout ................................................................................................. 44

3.3 How to Change Parts ................................................................................... 47

3.3.1 Upper Cover Assy..................................................................................................... 48

3.3.2 IC Card Cover........................................................................................................... 49

3.3.3 LED Head ................................................................................................................. 50

3.3.4 Operator Panel Assy................................................................................................. 51

3.3.5 Lower Base Unit ....................................................................................................... 52

3.3.6 Pulse Motor (Main/Drum).......................................................................................... 53

3.3.7 Pulse Motor (Registration) ........................................................................................ 54

3.3.8 Face Up Stacker Assy .............................................................................................. 55

3.3.9 Eject Roller Assy....................................................................................................... 56

3.3.10 Motor Assy .............................................................................................................. 57

3.3.11 Hopping Roller Shaft Assy ...................................................................................... 58

3.3.12 Stacker Cover Assy ................................................................................................ 59

3.3.13 Registration Roller .................................................................................................. 60

3.3.14 Roller Transfer Assy................................................................................................ 61

3.3.15 Fusing Unit..............................................................................................................62

3.3.16 Back-up Roller ........................................................................................................ 63

3.3.17 Sensor Plate (Inlet) ................................................................................................. 64

3.3.18 Sensor Plate (Outlet) .............................................................................................. 65

3.3.19 Manual Feed Guide Assy........................................................................................ 66

3.3.20 Sensor Plate (Paper Supply) .................................................................................. 67

3.3.21 M5G-PCB ............................................................................................................... 68

3.3.22 Transformer ............................................................................................................ 69

3.3.23 Power Supply/Sensor Board and Contact Assy...................................................... 70

3.3.24 Cassette Guide L Assy ........................................................................................... 71

3.3.25 Cassette Guide R Assy........................................................................................... 72

3.3.26 Spacer Bearing (L/R) .............................................................................................. 73