Table of Contents Page

Service Manual for OKIPAGE 8z

0 Introduction

Preface 1

1 Configuration

Configuration 2

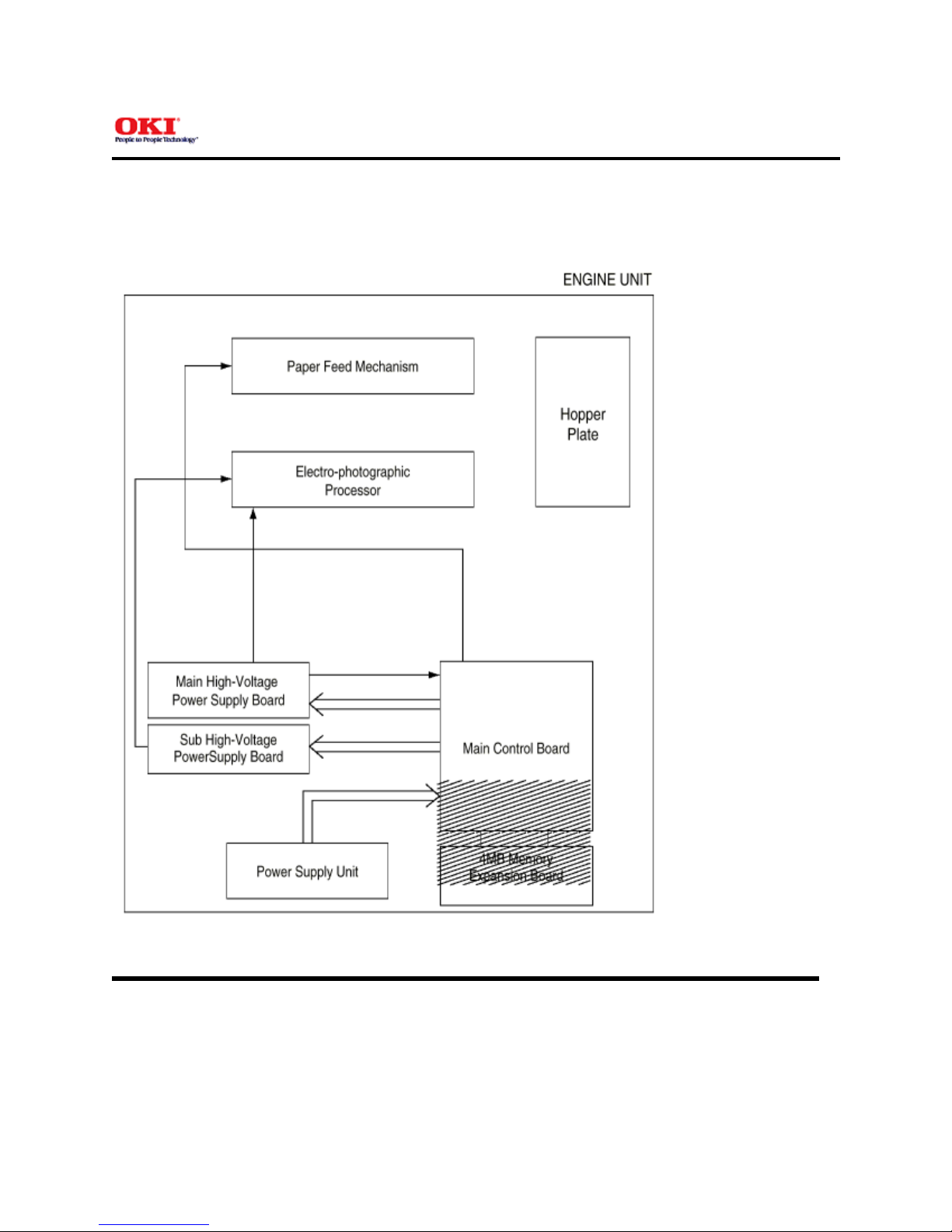

....1.1 System Configuration 3

....1.2 Printer Configuration 4

....1.3 Specification 5

....1.4 Safety Standards 6

........1.4.1 Certification Label 7

........1.4.2 Warning Label 8

2 Operation Description

2.0 Operation Description 9

2.1 Main Control Board 10

2.2 Power Supply Unit 11

2.3 High-Voltage Power Supply Board 12

2.4 Electro-Photographic Processor 13

2.5 Electro-Photographic Process 14

....2.5.1 Explanation of Each Process Operation 15

2.6 Paper Jam Detection 16

2.7 Toner Low Detection 17

2.8 Cover Open 18

2.9 Detecting ID existence 19

3 Parts Replacement

Parts Replacements 20

....3.1 Precautions for Parts Replacement 21

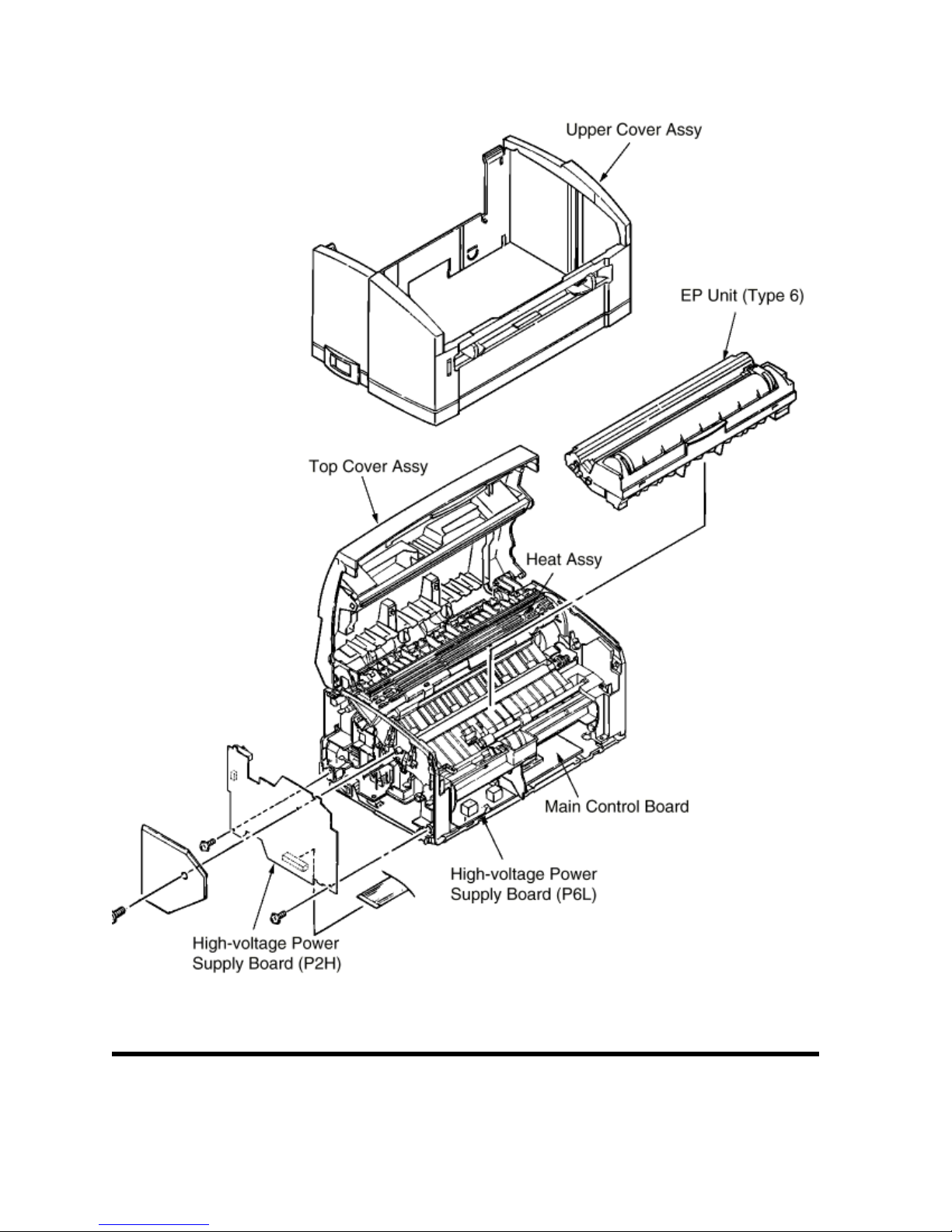

....3.2 Parts Layout 22

........Upper Cover Assy 23

........Base Frame Unit 24

........Base Plate Unit 25

....3.3 Replacing Parts 26

........3.3.1 Hopper Plate 27

........3.3.2 LED Head and Head Spring 28

........3.3.3 Transfer Roller 29

........3.3.4 Upper Cover Assy 30

........3.3.5 High-Voltage Power Supply Board (P2H/P6L) 31

........3.3.6 Top Cover Assy and Flat Cable Assy 32

........3.3.7 Paper Holder 33

........3.3.8 Side Plate M and Idle Gear 34

........3.3.9 Heat Assy 35

........3.3.10 Drive Shaft E (Eject) and Eject Roller 36

........3.3.11 Pressure Roller B (Back Up Roller) 37

........3.3.12 Separator Guide 38

........3.3.13 Pulse Motor (Main) 39

........3.3.14 Hopping Shaft Assy 40

........3.3.15 Resist Roller 41

........3.3.16 Paper Sensor E, Paper Sensor Exit and Toner

Sensor Assy 42

........3.3.17 Base Plate 43

4 Adjustment

4.0 Adjustment 44