D-11E2AX

E2AX

Specifications

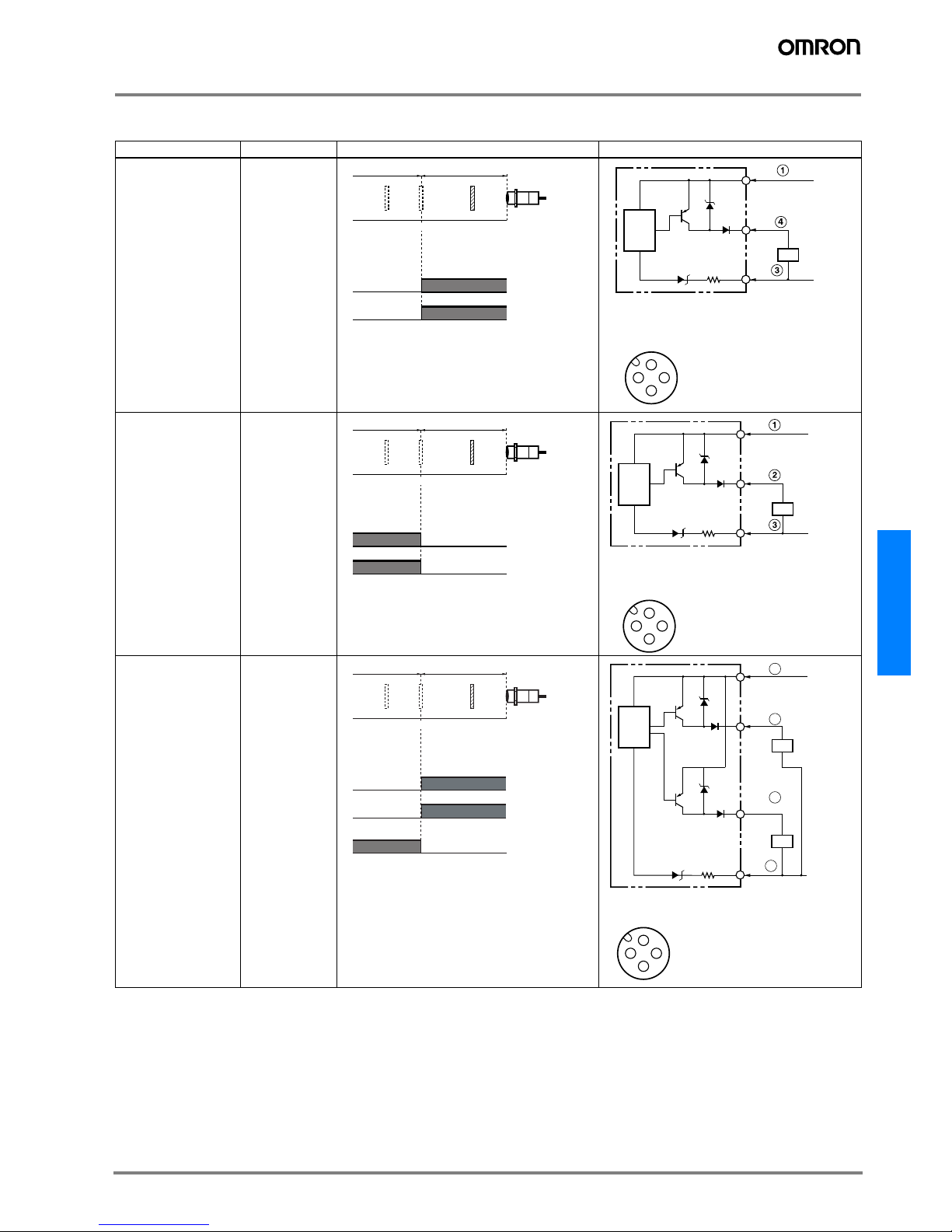

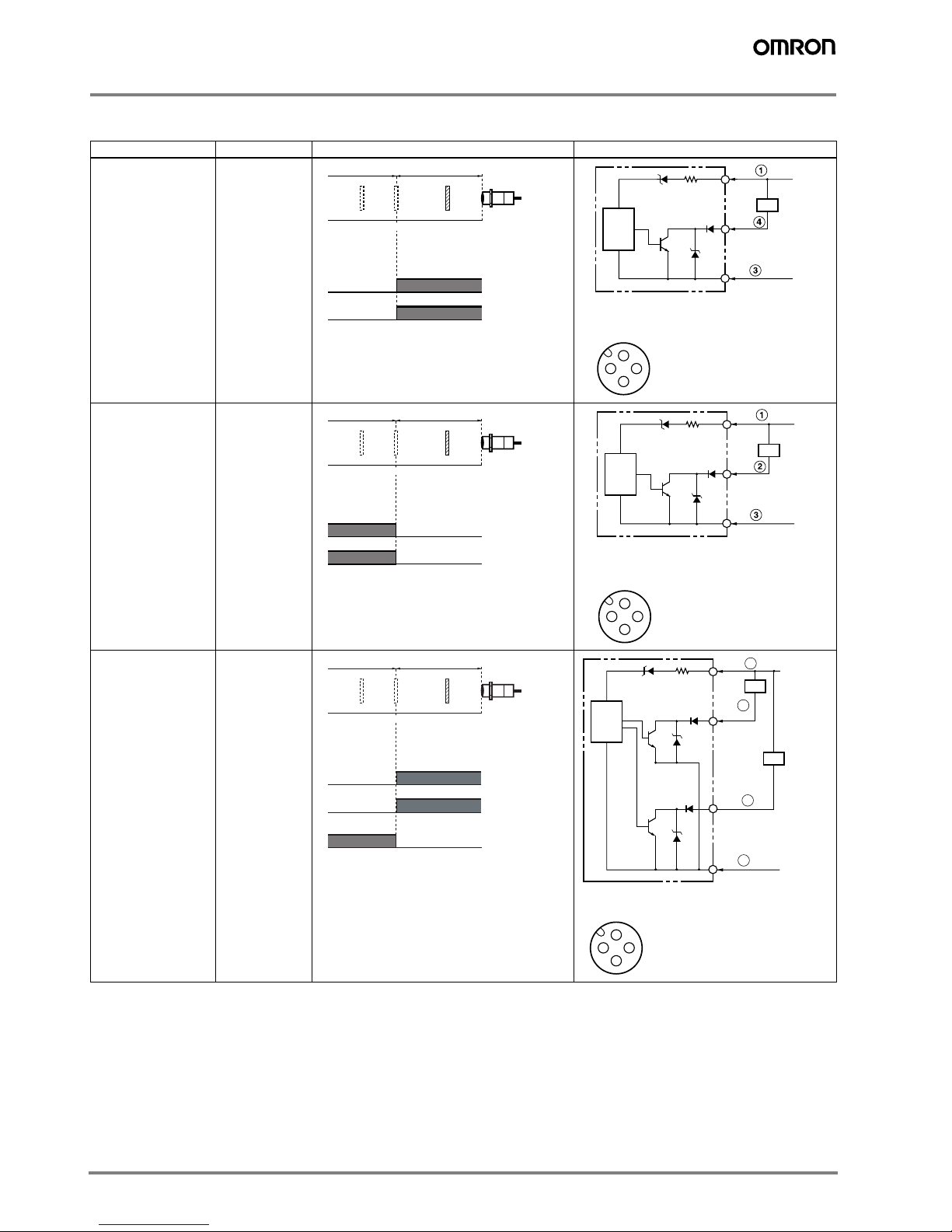

DC 3-wire Models / DC 4-wire (NO+NC)

Note 1. The response frequency is an average value. Measurement conditions are as follows: standard target, a distance of twice the standard

target distance between targets, and a setting distance of half the sensing distance.

2. When using any model at an ambient temperature between −40°C and −25°C and a power voltage between 30 and 32 VDC, use a load

current of 100 mA max.,

3. For USA and Canada: Use class 2 circuit only.

Size M12

Type Shielded Non-shielded

Item

E2AX-M12

@

S04-

@@

-B

@

E2AX-M12

@

S04-

@@

-C

@

E2AX-S12

@

S04-

@@

-B

@

E2AX-S12

@

S04-

@@

-C

@

E2AX-M12

@

N08-

@@

-B

@

E2AX-M12

@

N08-

@@

-C

@

E2AX-S12

@

N08-

@@

-B

@

E2AX-S12

@

N08-

@@

-C

@

Sensing distance 4 mm ± 10% 8 mm ± 10%

Setting distance 0 to 3.2 mm 0 to 6.4 mm

Differential travel 10% max. of sensing distance

Target Ferrous metal (The sensing distance decreases with non-ferrous metal.)

Standard target (mild steel ST37) 12×12×1 mm 24×24×1 mm

Response frequency (See note 1.) 1,000 Hz 800 Hz

Power supply voltage

(operating voltage range)

12 to 24 VDC. Ripple (p-p): 10% max.

(10 to 32 VDC)

Current consumption (DC 3-wire) 10 mA max.

Output type -B models: PNP open collector

-C models: NPN open collector

Control

output

Load current

(See note 2.) 200 mA max. (32 VDC max.)

Residual voltage 2 V max. (under load current of 200 mA with cable length of 2 m)

Indicator Operation indicator (Yellow LED)

Operation mode

(with sensing object approaching)

-B1/-C1 models: NO

-B2/-C2 models: NC

-B3/ -C3 models: NO+NC

For details, refer to the timing charts.

Protection circuit Output reverse polarity protection, Power source circuit reverse polarity protection, Surge suppressor,

Short-circuit protection

Ambient air temperature Operating: −40°C to 70°C, Storage: −40°C to 85°C (with no icing or condensation)

Temperature influence (See note 2.) ±10% max. of sensing distance at 23°C within temperature range of −25°C to 70°C

±15% max. of sensing distance at 23°C within temperature range of −40°C to 70°C

Ambient humidity Operating: 35% to 95%, Storage: 35% to 95%

Voltage influence ±1% max. of sensing distance in rated voltage range ±15%

Insulation resistance 50 MΩmin. (at 500 VDC) between current carry parts and case

Dielectric strength 1,000 VAC at 50/60 Hz for 1 min between current carry parts and case

Vibration resistance 10 to 55 Hz, 1.5-mm double amplitude for 2 hours each in X, Y and Z directions

Shock resistance 1,000 m/s2, 10 times each in X, Y and Z directions

Standard and listings (See note 3.)

IP65

EMC after EN60947-5-2

ATEX after EN50014

EN50281-1-1/2

Connection method Please see chapter ’Connectivity’ for details on M12 connectors.

Weight

(packaged) Connector model Approx. 35 g

Material

Case Brass-nickel plated or stainless steel

Sensing surface PBT

Clamping nut Brass-nickel plated for brass models stainless steel for steel models