!

5Application Precautions

xiv

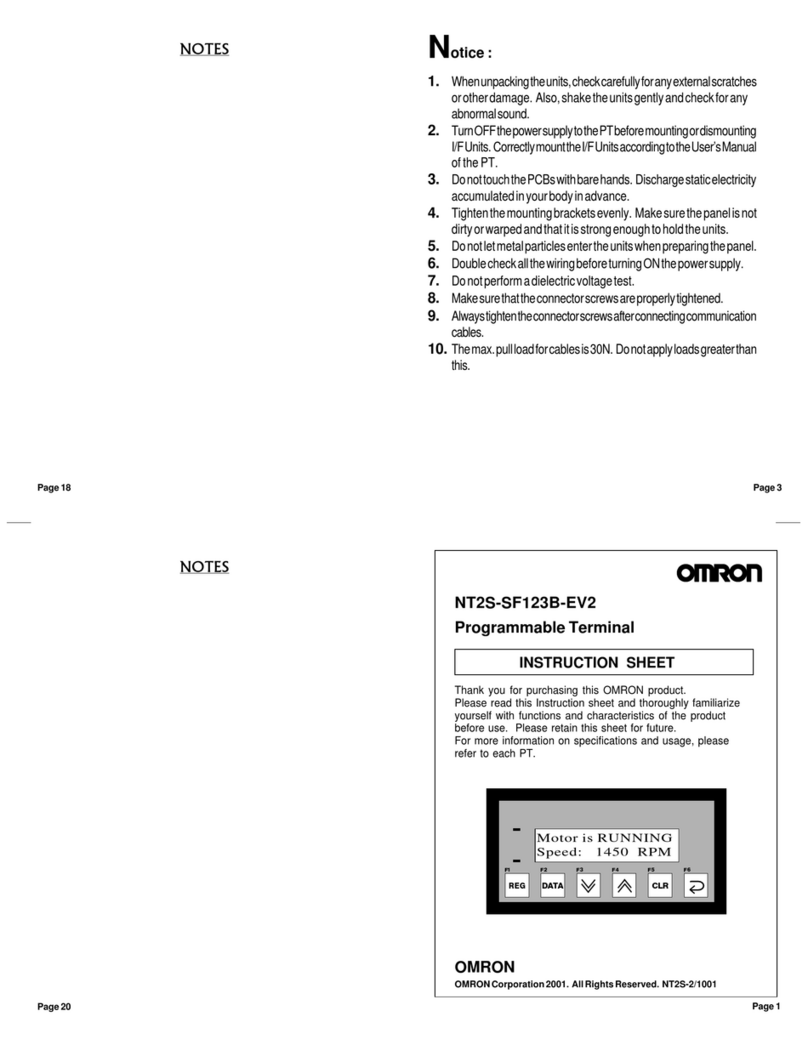

•Always turn OFF the power supply to the PC before attempting any of the fol-

lowing. Not turning OFF the power supply may result in malfunction or electric

shock.

•Mounting or dismounting I/O Units, CPU Units, Memory Cassettes, or any

other Units.

•Assembling the Units.

•Setting DIP switches or rotary switches.

•Connecting or wiring the cables.

•Connecting or disconnecting the connectors.

Caution Failure to abide by the following precautions could lead to faulty operation of the

PC or the system, or could damage the PC or PC Units. Always heed these pre-

cautions.

•Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused by broken signal lines,

momentary power interruptions, or other causes.

•Construct a control circuit so that power supply for the I/O circuits does not

come ON before power supply for the Unit. If power supply for the I/O circuits

comes ON before power supply for the Unit, normal operation may be tempo-

rarily interrupted.

•If the operating mode is changed from RUN or MONITOR mode to PROGRAM

mode, with the IOM Hold Bit ON, the output will hold the most recent status. In

such a case, ensure that the external load does not exceed specifications. (If

operation is stopped because of an operation error (including FALS instruc-

tions), the values in the internal memory of the CPU Unit will be saved, but the

outputs will all turn OFF.)

•Always use the power supply voltage specified in the operation manuals. An

incorrect voltage may result in malfunction or burning.

•Take appropriate measures to ensure that the specified power with the rated

voltage and frequency is supplied. Be particularly careful in places where the

power supply is unstable. An incorrect power supply may result in malfunction.

•Install external breakers and take other safety measures against short-circuit-

ing in external wiring. Insufficient safety measures against short-circuiting may

result in burning.

•Do not apply voltages to the input terminals in excess of the rated input voltage.

Excess voltages may result in burning.

•Do not apply voltages or connect loads to the output terminals in excess of the

maximum switching capacity. Excess voltage or loads may result in burning.

•Disconnect the functional ground terminal when performing withstand voltage

tests. Not disconnecting the functional ground terminal may result in burning.

•Install the Unit properly as specified in the operation manual. Improper installa-

tion of the Unit may result in malfunction.

•Be sure that all the mounting screws, terminal screws, and cable connector

screws are tightened to the torque specified in the relevant manuals. Incorrect

tightening torque may result in malfunction.

•Be sure to leave the labels attached at the time of shipment on the CPM1 or

CPM2A when wiring in order to prevent wiring cuttings from entering the Unit.

•Remove the label after the completion of wiring to ensure proper heat dissipa-

tion. Leaving the label attached may result in malfunction.

•Be sure to perform wiring in accordance with the relevant operation manual.

Incorrect wiring may result in burning.

•Use crimp terminals for wiring. Do not connect bare stranded wires directly to

terminals. Connection of bare stranded wires may result in burning.