About this Manual

Manual 1: Setup Manual

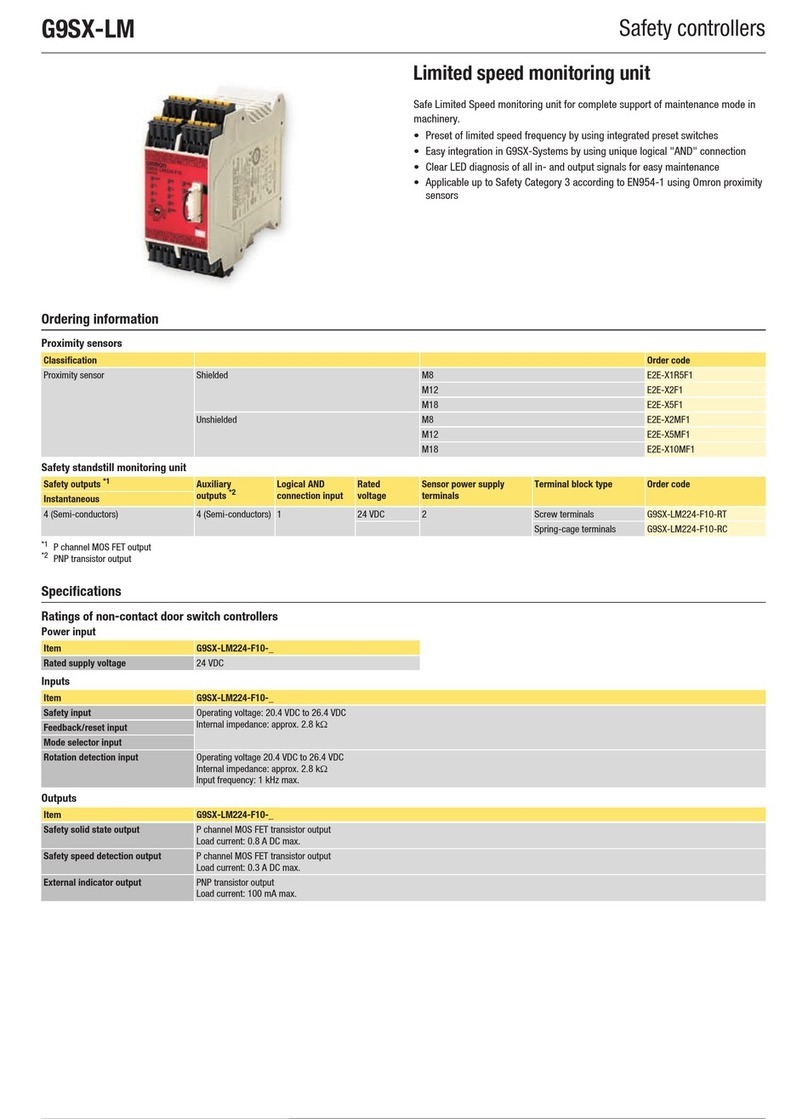

Installation

Wiring

Please read the following manuals carefully and be sure you understand the information provided

before attempting to install or operate the Z500.

This manual describes the hardware for the Z500

(Multi-Dimensional Controller) and how to install the

components.

Be sure to read this manual first.

Manual 2: Operation Manual

Starting the Z500

and Positioning

the Workpiece

Adjusting Images

Setting

Measurement

Conditions

and Executing

Outputting to

External Devices

SECTION 2 Basic Operations

This section describes how to start the Z500

and how to display images on the monitor.

SECTION 7 I/O Format

This section provides details on the inputs and outputs

used for communications with external devices via

terminal blocks or RS-232C.

• Communications settings

• I/O format

• Timing for communications

SECTION 3

Menus for Conversational Menu

• Basic settings required for measurement

• Measurement of consistent workpieces

Menus for Conversational Menu

Settings can be made easily by entering

information as requested - just as

though you are having a conversation

with the Z500.

SECTION 4 Menus for Expert Menu

• Customized settings

• Detailed settings

• Measurement of workpieces placed at different

positions

Menus for Expert Menu

More detailed setting, such as position

compensation for workpieces placed at

different positions, can be made.

Cat. No. Z159-E1-2

Multi-Dimensional Controller

Z500

Operation Manual

Manual

Cat.No. Z000-E1-1

Cat. No. Z158-E1-2

Multi-Dimensional Controller

Setup Manual

Manual

Cat.No. Z000-E1-1

Multi-Dimensional Controller

Z500

OMRON Corporation

Industrial Automation Company

Application Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 Japan

Tel:(81)75-344-7068 / Fax:(81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz Str. 4, D-71154 Nufringen,

Germany

Tel:(49)7032-811-0 / Fax:(49)7032-811-199

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel:(1)847-843-7900 / Fax:(1)847-843-8568

OMRON ASIA PACIFIC PTE.LTD.

83 Clemenceau Avenue, #11-01, UE Square,

239920 Singapore

Tel:(65)835-3011 / Fax:(65)835-2711

OMRON CHINA CO.,LTD.

BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No.88 West Chang'an Road,

Beijing, 100031 China

Tel:(86)10-8391-3005 / Fax:(86)10-8391-3688