S8VK-G

3

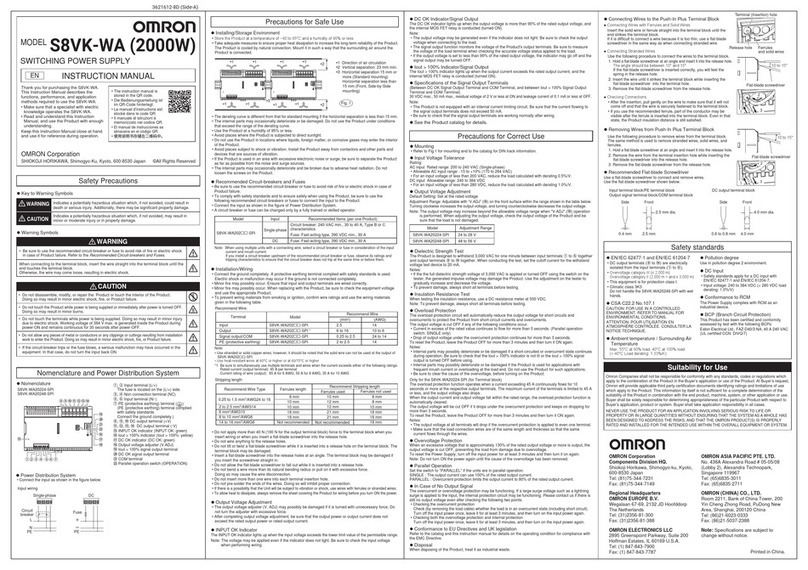

Specifications

Ratings, Characteristics, and Functions

*1.

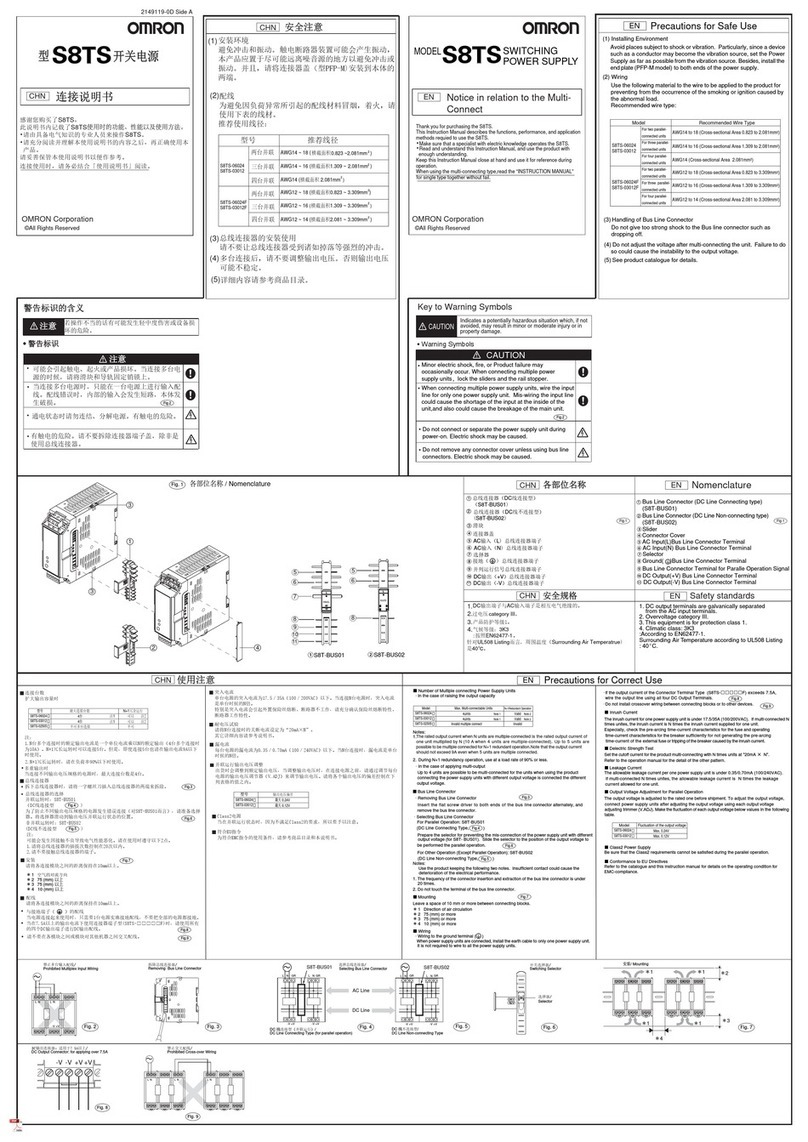

Do not use an inverter output for the Power Supply. Inverters with an output frequency of 50/60 Hz are available, but the rise in the internal temperature of the Power Supply

may result in ignition or burning.

*2. For a cold start at 25°C. Refer to Engineering Data on page 9 to 11 for details.

*3.

If the output voltage adjuster (V. ADJ) is turned, the voltage will increase by more than +15% of the voltage adjustment range. When adjusting the output voltage, confirm

the actual output voltage from the Power Supply and be sure that the load is not damaged.

*4. A characteristic when the ambient operating temperature is between –25 to 70°C.

*5. Refer to Overvoltage Protection on page 10 for the time when input voltage shuts off and input turns on again.

*6. The value is when both rated output voltage and rated output current are satisfied.

*7. 100 to 240 VAC input, in the range of 0 A to the rated output current

*8.

This is the maximum variation in the output voltage when the input voltage is gradually changed within the allowable input voltage range at the rated output voltage and rated output current.

*9. Refer to Recommended Replacement Periods and Periodic Replacement for Preventive Maintenance on page 22 for details.

*10. Safety Standards for a DC Input

The following safety standards apply to a DC input: UL 60950-1, cUR (CSA C22.2 No. 60950-1), EN 50178, EN 60950-1, and Lloyd’s.

For a DC input, safety is ensured by an external fuse.

Select an external fuse that meets the following conditions.

S8VK-G015@@: 350 VDC min, 3 A

S8VK-G030@@: 350 VDC min, 4 A

*11.

Clamp filter “ZCAT2035-0930” manufactured by TDK Corporation. or equivalent should be installed in the cable connected to the input - output terminals of S8VK-G series.

Noise filter “FN2080-10-06” manufactured by SCHAFFNER Corporation. or equivalent should be connected to the Input terminals of S8VK-G series.

*12.At −40 to −25°C, time will be required before the rated output voltage is output after the input voltage is input.

Also, the ripple noise value may exceed the value shown in the above table.

Power rating 15 W 30 W

Item Output voltage 5 V 12 V 24 V 5 V 12 V 24 V

Efficiency 230 VAC input *677% typ. 77% typ. 80% typ. 79% typ. 82% typ. 86% typ.

Input

Voltage range *1Single-phase, 85 to 264 VAC, 90 to 350 VDC *10

Frequency *150/60 Hz (47 to 450 Hz)

Current 115 VAC input *60.32 A typ. 0.3 A typ. 0.31 A typ. 0.5 A typ. 0.57 A typ. 0.58 A typ.

230 VAC input *60.2 A typ. 0.21 A typ. 0.2 A typ. 0.32 A typ. 0.37 A typ. 0.36 A typ.

Power factor

230 VAC input, 100% load

0.42 min. 0.43 min. 0.42 min. 0.43 min.

Leakage current 115 VAC input 0.14 mA typ. 0.13 mA typ.

230 VAC input 0.25 mA typ. 0.24 mA typ.

Inrush current

*

2 (for

a cold start at 25

°

C)

115 VAC input 16 A typ 16 A typ

230 VAC input 32 A typ. 32 A typ.

Output

Rated output current 3 A 1.2 A 0.65 A 5 A 2.5 A 1.3 A

Boost current 3.6 A 1.44 A 0.78 A 6 A 3 A 1.56 A

Voltage adjustment range *3–10% to 15% (with V.ADJ) (guaranteed)

Ripple & Noise

voltage *4

100 to 240 VAC input,

100% load *6

60 mVp-p max. at 20

MHz of bandwidth

50 mVp-p max.at 20

MHz of bandwidth

30 mVp-p max. at 20

MHz of bandwidth

30 mVp-p max. at 20

MHz of bandwidth

30 mVp-p max. at 20

MHz of bandwidth

30 mVp-p max. at 20

MHz of bandwidth

Input variation influence *80.4% max. 0.4% max.

Load variation influence *70.8% max. 0.8% max.

Temperature variation

influence

115 to 230 VAC input 0.05%/°C max. 0.05%/°C max.

Start up time *2115 VAC input *6530 ms typ. 520 ms typ. 580 ms typ. 550 ms typ. 550 ms typ. 600 ms typ.

230 VAC input *6330 ms typ. 400 ms typ. 400 ms typ. 430 ms typ. 490 ms typ. 480 ms typ.

Hold time *2115 VAC input *628 ms typ. 29 ms typ. 32 ms typ. 33 ms typ. 36 ms typ. 23 ms typ.

230 VAC input *6134 ms typ. 138 ms typ. 134 ms typ. 177 ms typ. 170 ms typ. 154 ms typ.

Additional

functions

Overload protection Yes, automatic reset Yes, automatic reset

Overvoltage protection *5

Yes, 130% or higher of rated output voltage, power shut off (shut off the input voltage and turn on the input again)

Series operation Yes (For up to two Power Supplies, external diodes are required.)

Parallel operation Yes (Refer to Safety Precautions) (For up to two Power Supplies)

Output indicator Yes (LED: Green), lighting from 80% to 90% or more of rated voltage

Insulation Withstand voltage

3.0 kVAC for 1 min. (between all input terminals and output terminals), current cutoff 20 mA

2.0 kVAC for 1 min. (between all input terminals and PE terminals), current cutoff 20 mA

1.0 kVAC for 1 min. (between all output terminals and PE terminals), current cutoff 20 mA

Insulation resistance 100 MΩmin. (between all output terminals and all input terminals/PE terminals) at 500 VDC

Environment

Ambient operating temperature *12

–40 to 70°C (Derating is required according to the temperature. Refer to

Engineering Data

) (with no condensation or icing)

Storage temperature –40 to 85°C (with no condensation or icing)

Ambient operating humidity 0% to 95% (Storage humidity: 0% to 95%)

Vibration resistance 10 to 55 Hz, 0.375 mm half amplitude for 2 h each in X, Y, and Z directions

Shock resistance 150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

Reliability MTBF 135,000 hrs min.

Life expectancy *9 10 years min.

Construction

Weight 150 g max. 195 g max.

Cooling fan No

Degree of protection IP20 by EN/IEC 60529

Standards

Harmonic current emissions Conforms to EN 61000-3-2

EMI Conducted Emissions Conforms to EN 61204-3 Class B, EN 55011 Class B

Radiated Emissions Conforms to EN 61204-3 Class B, EN 55011 Class B

EMS Conforms to EN 61204-3 high severity levels

Approved Standards

UL Listed: UL 508 (Listing, Class2 Output: Per UL 1310)

UL UR: UL 60950-1 (Recognition)

cUL: CSA C22.2 No.107.1 (Class2 Output: Per CSA C22.2 No.223)

cUR:CSA C22.2 No.60950-1

EN/VDE: EN 50178, EN 60950-1

ANSI/ISA 12.12.01

Conformed Standards PELV (EN 60204-1, EN 50178)

EN 61558-2-16

Marine Standards Lloyd’s register *10 *11

SEMI Conforms to F47-0706 ( 200 to 240 VAC input)

![Omron CP1E-N[]S1 User manual Omron CP1E-N[]S1 User manual](/data/manuals/1j/0/1j0uf/sources/omron-cp1e-n-s1-power-supply-manual.jpg)