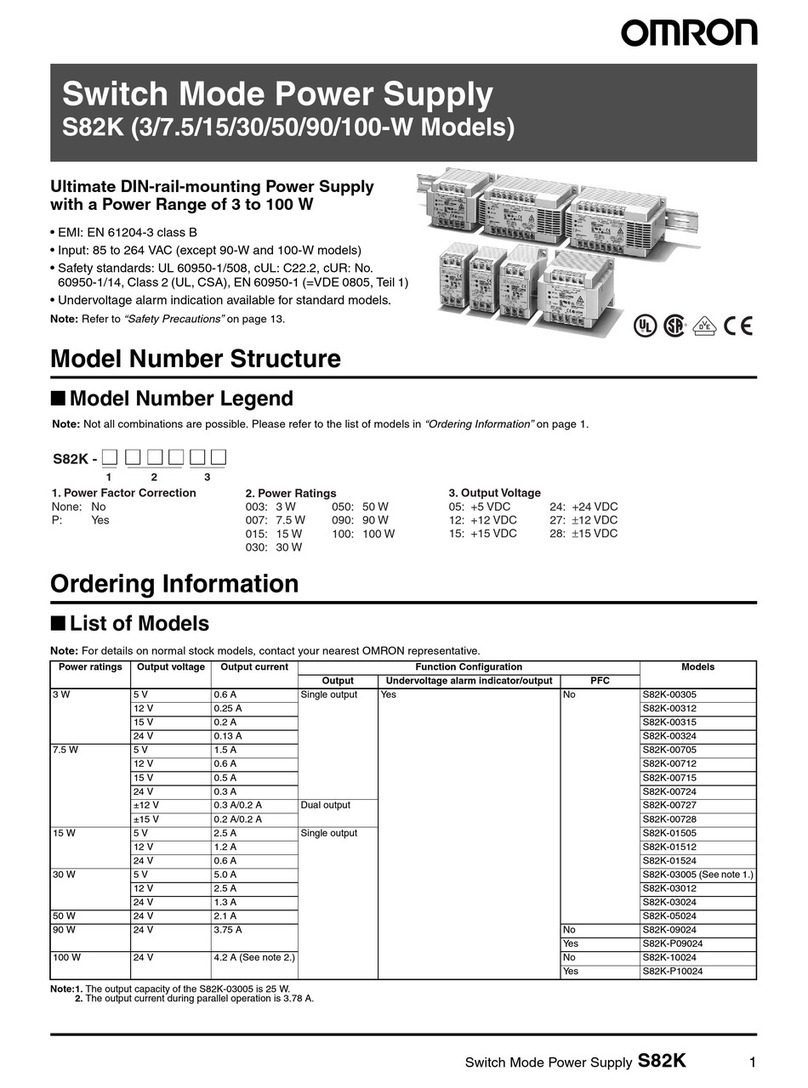

6Switching Mode Power Supply ZEN-PA03024

Safety Precautions

Minor electric shock may occasionally occur. Do not disassemble

the product or touch internal parts.

Minor fires may occasionally occur. Do not attempt to repair or

modify the product.

Minor burns may occasionally occur. Do not touch the product

while power is being supplied or immediately after power is

turned OFF.

Minor fires may occasionally occur. Tighten terminal screws to a

torque of 0.5 to 0.6 N·m so that they do not become loose.

Minor electric shock may occasionally occur during operation. Do

not touch the input and output terminals while power is being

supplied.

The product may occasionally be damaged. Do not allow any

clippings or cuttings to enter the product during installation work.

Working voltage can be 350 V max. inside. This voltage can be

also available 10 s after the switch off.

■Precautions for Safe Use

The following precautions must be observed to ensure safety.

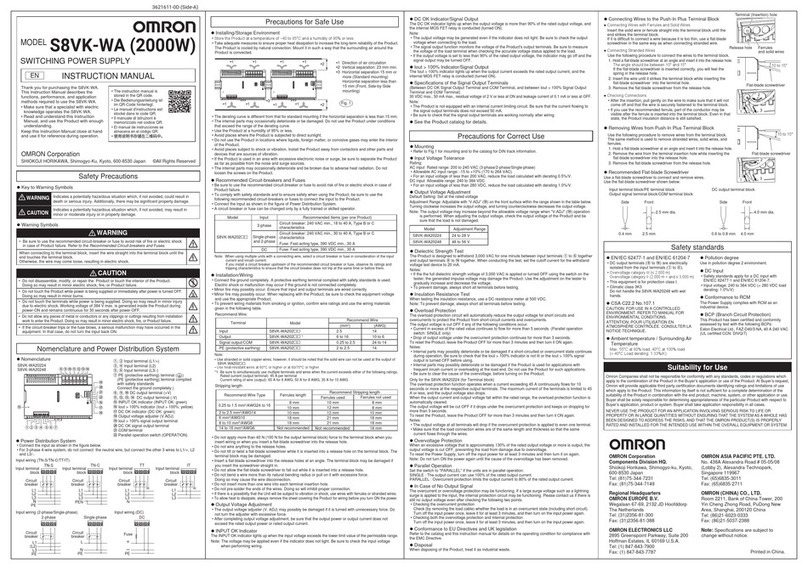

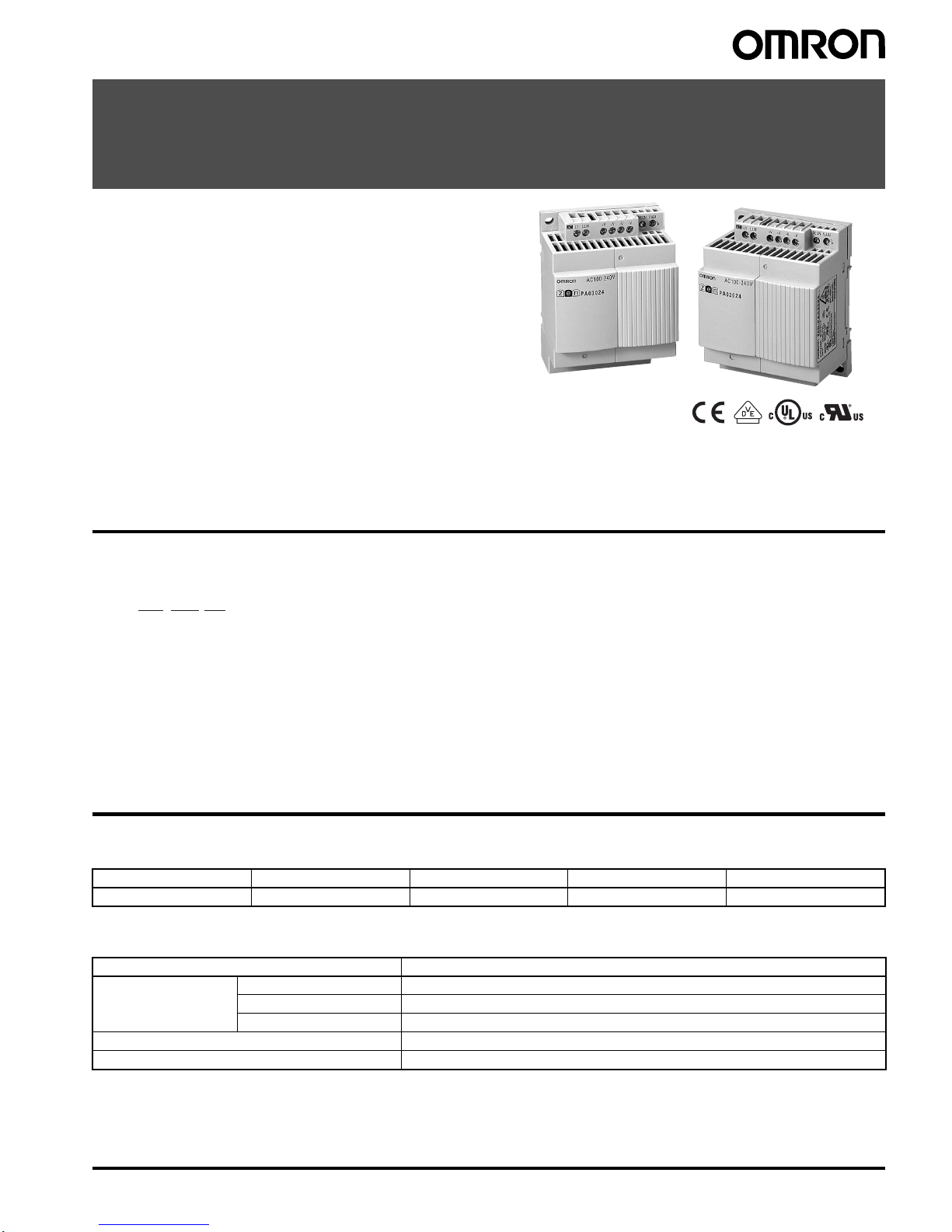

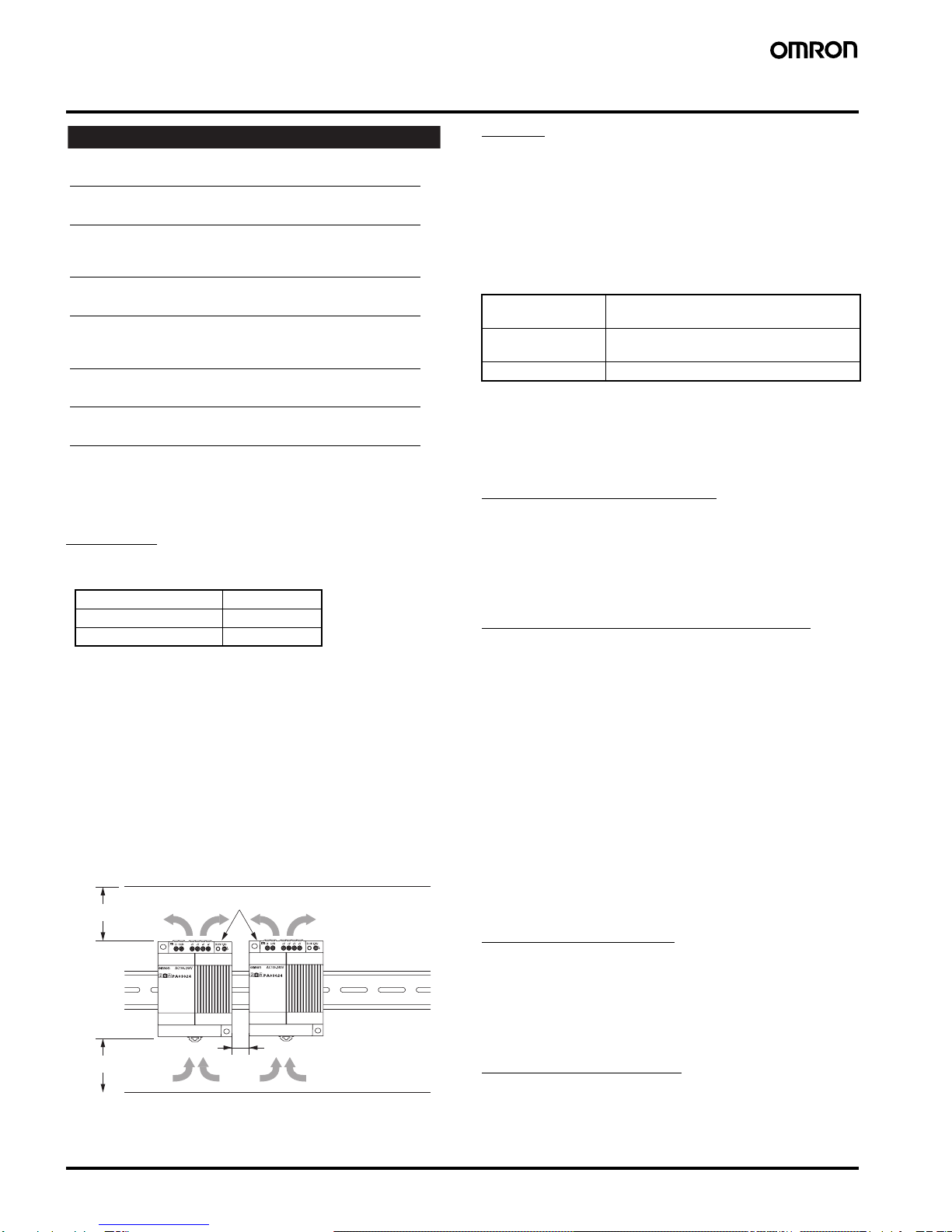

Mounting

•Mounting Direction

(Refer to Installation in Engineering Data on page 4.)

The internal parts may occasionally deteriorate or be broken due to

adverse heat dissipation depending on the mounting status. Do not

use the product in any way other than the standard mounting

direction.

•Mounting Space

Make sure that sufficient heat dissipation is provided when

installing the Power Supply to increase its long-term reliability.

Install the product in a location that allows a natural airflow to occur

around the Power Supply.

We recommend using End Plates (PFP-M) to secure the Power

Supply and to ensure that a space of at least 10 mm is maintained

between Power Supplies.

If the installation space above and below the Power Supply is less

than 50 mm, reduce the ambient temperature by 5°C. A minimum

space of 20 mm is required.

Note: 1. Convection of air

2. 50 mm min.

3. 10 mm min.

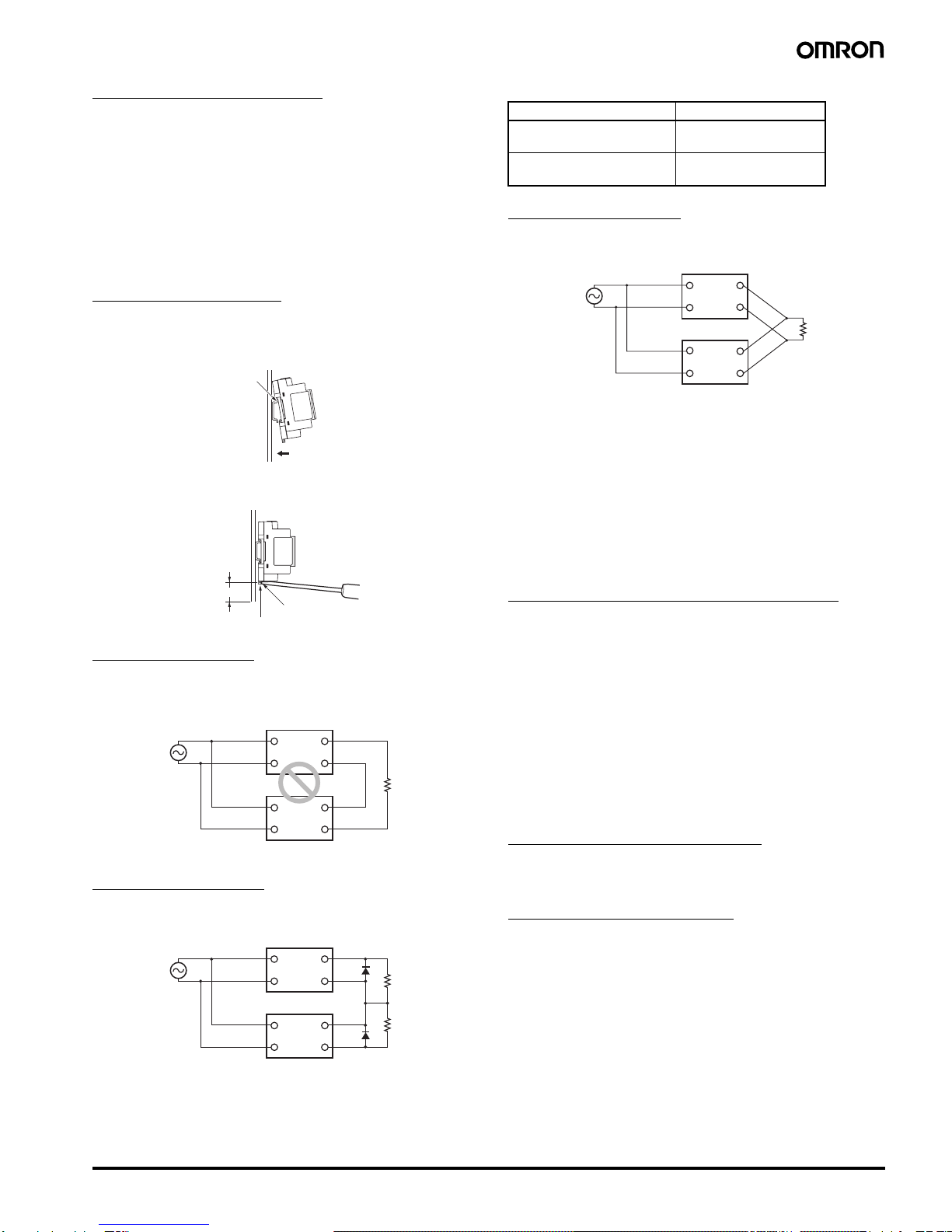

Wiring

•Minor fire may possibly occur. Ensure that input and output

terminals are wired correctly.

•Use the following material for the wires to be connected to the

Power Supply to prevent smoking or ignition caused by abnormal

loads.

Use solid wires. Always attach pin crimp terminals when using

stranded wire. The stripping distance should be 6.5 mm.

Recommended Wire Type

•Do not apply more than 100 N force to the terminal block when

tightening the terminals.

•Be sure to remove the sheet covering the product before turning

ON the Power Supply and confirm that nothing is interfering with

heat dissipation.

Installation Environment

•Do not use the Power Supply in locations subject to shocks or

vibrations. In particular, install the Power Supply as far away as

possible from contactors or other devices that are a vibration

source.

•Install the Power Supply well away from any sources of strong,

high-frequency noise.

Operating and Storage Conditions

•When installing the Power Supply, check for any signs that the

product or packaging has been struck. If internal parts have been

damaged, overvoltages may be output depending on the location of

the damage.

•Internal parts may occasionally deteriorate or be damaged. Store

the Power Supply at a temperature of -25 to 65°C and a humidity of

10% to 90%.

•Internal parts may occasionally deteriorate or be damaged. Do not

use the Power Supply in areas outside the derating curve (i.e., the

area shown by shading (1) in the graph on page 4). For UL508

Listing, the surrounding air temperature should be 40°C.

•Use the Power Supply at a humidity of 10% to 90%.

•Do not use the Power Supply in locations where condensation may

occur due to high humidity or where temperature changes are

severe.

•Do not use the Power Supply in locations subject to direct sunlight.

•Do not use the Power Supply in locations where liquids, foreign

matter, or corrosive gases may enter the interior of products.

Overload Protection

•Internal parts may possibly deteriorate or be damaged if a short-

circuited or overcurrent state continues during operation.

•Internal parts may possibly deteriorate or be damaged if the Power

Supply is used for applications with frequent inrush current or

overloading at the load end. Do not use the Power Supply for such

applications.

Charging the Battery

•This product is not intended to function as a battery charger. If a

battery is to be connected as the load, mount an overcurrent

limiting circuit and an overvoltage protection circuit.

Standard Mounting Valid

Horizontal Mounting Invalid

Other Mounting Invalid

!CAUTION

(See note 1.)

(See note 1.)

(See note 2.)

(See note 2.)

ZEN-PA03024

(See note 3.)

Solid wire Cross section 0.5 to 2.5 mm2

(Equivalent to AWG20 to AWG14)

Stranded wire Cross section 0.5 to 2.5 mm2

(Equivalent to AWG20 to AWG14)

Pin crimp terminals Dia.: 1.1 to 2.3 mm