ModelF3SJ-B□□□□P25-02TS

1. An F3SJ-B does not receive type approval provided by Article 44-2 of the

Labour Safety and Health Law of Japan. Therefore, the F3SJ-B cannot be

used as a "safety system for pressing or shearing machines" prescribed in

Article 42 of that law.

2. The F3SJ-B is electro-sensitive protective equipment (ESPE) in accordance

with European Union (EU) Machinery Directive Index Annex V, Item 2.

3. The F3SJ-B is in conformity with the following standards:

(1) European standards

EN 61496-1 (Type 4 ESPE), EN 61496-2 (Type 4 AOPD),

EN 61508-1 through -3 (SIL3), EN 61000-6-4,

EN ISO 13849-1:2015 (Category 4, PL e)

(2) International standards

IEC 61496-1 (Type 4 ESPE), IEC 61496-2 (Type 4 AOPD),

IEC 61508-1 through -3 (SIL3), ISO 13849-1:2015 (Category 4, PLe)

(3) JIS standards

JIS B 9704-1 (Type 4 ESPE), JIS B 9704-2 (Type 4 AOPD)

(4) North American Standards:

UL 61496-1 (Type 4 ESPE), UL 61496-2 (Type 4 AOPD), UL 508,

UL 1998, CAN/CSAC22.2 No.14, CAN/CSA C22.2 No.08

4. The F3SJ-B received the approvals of EC Type-Examination in accordance

with the EU Machinery Directive, Type 4 ESPE and Type 4 AOPD from

the EU accredited body, TÜV SÜD Product Service GmbH.

5. The F3SJ-B received the certificates of UL listing for US and Canadian

safety standards, Type 4 ESPE and Type 4 AOPD from the Third Party

Assessment Body UL.

6. The F3SJ-B is designed according to the standards listed below. To make

sure that the final system complies with the following standards and

regulations, you are asked to design and use it in accordance with all other

related standards, laws, and regulations. If you have any questions, consult

with specialized organizations such as the body responsible for prescribing

and/or enforcing machinery safety regulations in the location where the

equipment is to be used.

•European Standards: EN415-4, EN692, EN693

•U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.212

•U.S. Occupational Safety and Health Standards: OSHA 29 CFR 1910.217

•American National Standards: ANSI B11.1 to B11.19

•American National Standards: ANSI/RIA 15.06

•Canadian Standards Association CSA Z142, Z432, Z434

•SEMI Standards SEMI S2

•Japan Ministry of Health, Labour and Welfare "Guidelines for

Comprehensive Safety Standards of Machinery", Standard Bureau's

Notification No. 0731001 dated July 31, 2007.

©OMRON Corporation

2011-2022

All Rights Reserved.

Declaration of Conformity

Suitability for Use

Please read and understand this instruction sheet before

storing, installing, programming, operating, maintaining, or

disposing of the products. Please consult your OMRON

representative if you have any questions or comments.

Please refer to the User's Manual and the Quick Installation

Manual for detailed instructions on usage.

Observe the precautions described below to prevent operation failure, malfunctions, or undesirable effects on product performance.

■Storage conditions and installation environment

• Do not install, use, or store the F3SJ-B for a long time at a temperature or humidity out of the specified range.

• This is a class A product. In residential areas it may cause radio interference, in which case the Responsible Person may be required to take adequate measures to

reduce interference.

• Do not use radio equipment such as cellular phones, walkie-talkies, or transceivers near the F3SJ-B.

• Do not use F3SJ-B at altitudes over 1,000 meters.

■Wiring and installation

• Make sure to perform wiring while the power supply is OFF. Otherwise, the F3SJ-B may fail to operate due to the diagnosis function.

• Do not short-circuit output lines to +24 V line. Otherwise a fault of the F3SJ-B may occur.

• When extending the communication line with a cable (twisted-pair wire) other than the dedicated cable (F39-JD□□), use a cable with the same or superior

specifications. Connect the shield to the 0V line.

• Be sure that there is nothing in the detection zone and the stable-state indicator is turned ON after power is turned ON.

• Properly perform the wiring after confirming the signal names of all the terminals.

• Do not operate the control system until 2 seconds or more after turning ON the power of the F3SJ-B.

• Be sure to route the F3SJ-B cable separate from high-potential power lines or through an exclusive conduit.

• When using a commercially available switching regulator power supply, make sure to ground the FG terminal (frame ground terminal).

•

If the protective height is more than 545 mm, use Intermediate Brackets of specified quantities and locations according to the dimensions described in the User's Manual.

• Do not install the F3SJ-B close to a device that generates high-frequency noise. Otherwise, take sufficient blocking measures.

• Sharing the power supply with other devices may cause the F3SJ-E/B to be affected by noise or voltage drop. It is recommended that the F3SJ-E/B use a dedicated

power supply but do not share with other devices.

■Cleaning

Do not use thinner, benzene, or acetone for cleaning, because they affect the product's resin parts and paint on the extrusion.

■Object detection

The F3SJ-B cannot detect transparent and/or translucent objects.

PRECAUTIONS FOR CORRECT USE

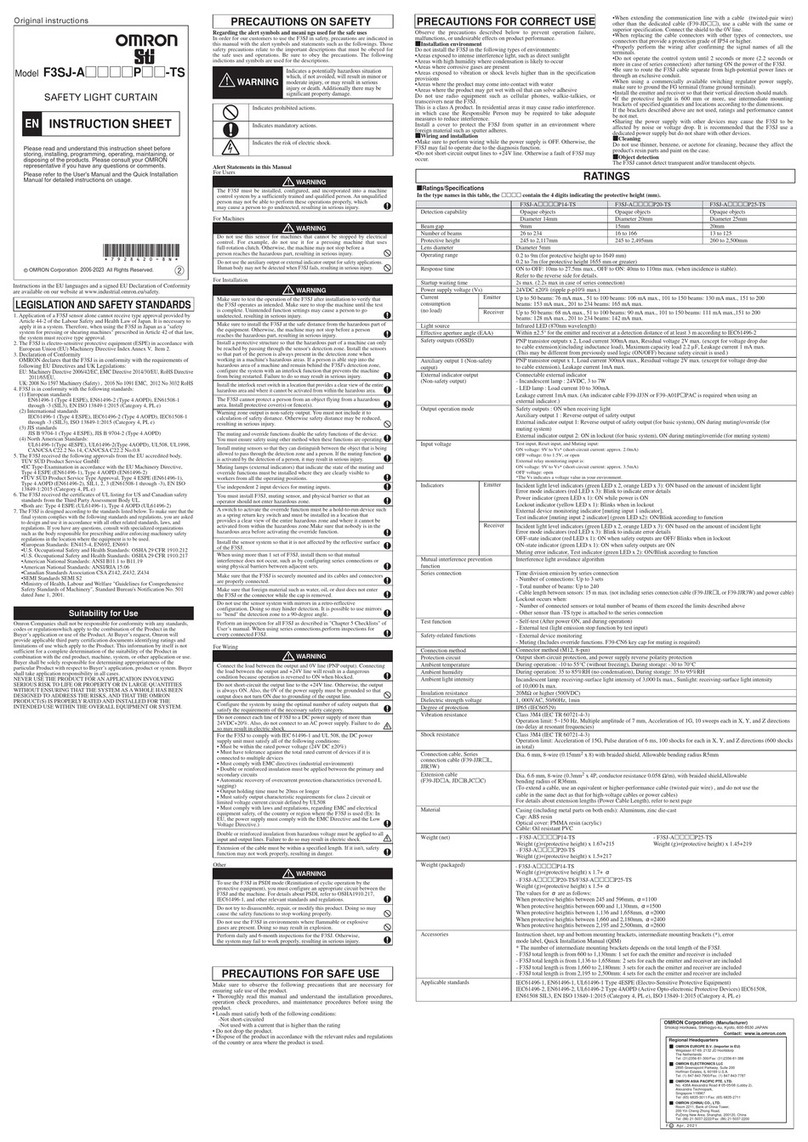

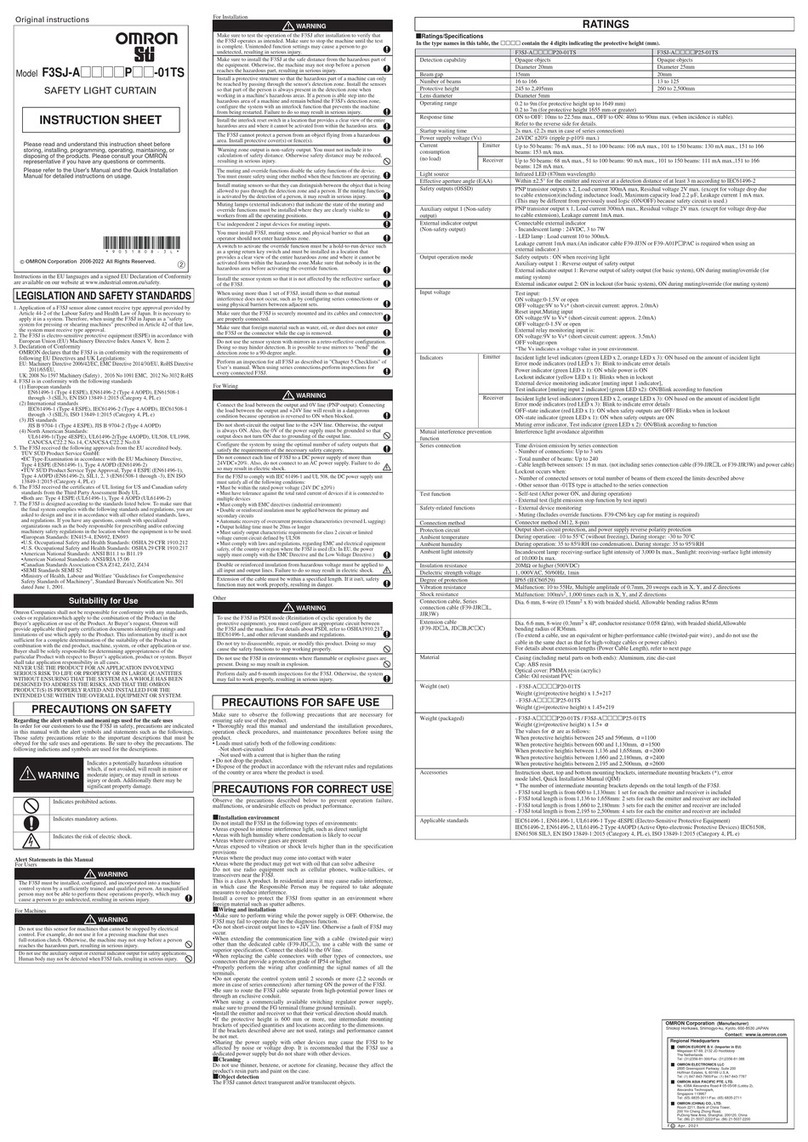

Internal Indicator

Input/Output Circuit

Original instructions

Not used

1

−

−

ON

Blinking

ON

Blinking

ON

Blinking

ON

Blinking

Blinking

Blinking

ON

ON

ON

Blinking

Blinking

Blinking

ON

Blinking

ON

Blinking

ON

Blinking

ON

Blinking

Turns ON when incidence level is

170% or more of the output ON

threshold.

Blinks when the safety output is

turned OFF due to disturbance

light or vibration.

Green: Output ON, Red: Output OFF

Output related error

During lockout

During lockout, error occurrence side

When power is ON

Error due to power supply voltage/noise

During emission stoppage

Muting error

Muting input 1 is ON

Muting input 2 is ON

When communication between

emitter and receiver is established.

Communication error

Model configuration of the connected

sensor is in error

Internal error

External device monitoring input is ON

External device monitoring error

Top beam is receiving light

During muting/override Cap

disconnection error sensor connection

error

Bottom beam is receiving light

During muting/override

ON/

Blinking Description

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Stable-state

indicator

ON/OFF

output-state

indicator

Lockout

indicator

Power

indicator

Test indicator

Muting error

indicator

Muting input 1

indicator

Muting input 2

indicator

Communication

indicator

Configuration

indicator

Internal error

indicator

External device

monitoring

indicator

Top-beam-state

indicator

Bottom-

beam-state

indicator

STB

ON/OFF

LOCKOUT

POWER

TEST

MUTING

ERROR

MUTE1

MUTE2

COM

CFG

INTERNAL

INTERLOCK

EDM

TOP

BTM

Omron Companies shall not be responsible for conformity with any

standards, codes or regulations which apply to the combination of the Product

in the Buyer’s application or use of the Product.At Buyer’s request, Omron

will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself

is not sufficient for a complete determination of the suitability of the Product

in combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FORAN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES

WITHOUT ENSURING THAT THE SYSTEM ASAWHOLE HAS BEEN

DESIGNED TOADDRESS THE RISKS, AND THAT THE OMRON

PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALLEQUIPMENT OR SYSTEM.

Alert Statements in this Manual

Meanings of Alert Symbols

Regarding the alert symbols and meanings used for the safe uses

In order to use the F3SJ-B safely, the precautions listed in this Instruction

Sheet indicated by alert symbols and descriptions must be followed. Failure

to follow all precautions and alerts may result in an unsafe use or operation.

The following indications and symbols are used for the descriptions.

The F3SJ-B must be installed, configured, and incorporated into a machine

control system by a sufficiently trained and qualified person. An

unqualified person may not be able to perform these operations properly,

which may cause a person to go undetected, resulting in serious injury.

Thoroughly read this manual and understand the installation procedures,

operation check procedures, and maintenance procedures before using

the product.

Do not use this sensor for machines that cannot be stopped by electrical

control. For example, do not use it for a pressing machine that uses

full-rotation clutch. Otherwise, the machine may not stop before

a personreaches the hazardous part, resulting in serious injury.

PRECAUTIONS ON SAFETY

Indicates a potentially hazardous situation

which, if not avoided, will result in minor or

moderate injury, or may result in serious

injury or death. Additionally there may be

significant property damage.

WARNING

WARNING

WARNING

For Users

For Machines

Indicates prohibited actions.

Indicates mandatory actions.

Indicates the risk of electric shock.

Make sure to test the operation of the F3SJ-B after installation to verify

that the F3SJ-B operates as intended. Make sure to stop the machine until

the test is complete. Unintended function settings may cause a person

to go undetected, resulting in serious injury.

Install a protective structure so that the hazardous part of a machine can only

be reached by a person that passes through the sensor's detection zone. Install

the sensors so that part of the person is always present in the detection zone

when working in a machine's hazardous zones, eliminating areas where the

sensors do not reach. If a person is able step into the hazardous zone of a

machine and remain behind the F3SJ-B's detection zone, configure the

system with an interlock function that prevents the machine from being

restarted. Failure to do so may result in serious injury.

Make sure to install the F3SJ-B at the safe distance from the hazardous

part of the equipment. Otherwise, the machine may not stop before

a person reaches the hazardous part, resulting in serious injury.

Install the interlock reset switch in a location that provides a clear view

of the entire hazardous zone and where it cannot be activated from

within the hazardous zone.

The F3SJ-B cannot protect a person from a projectile exiting the

hazardous zone. Install protective cover(s) or fence(s).

Install the F3SJ-B so that it is not affected by a reflective surface.

Failure to do so may hinder detection, resulting in serious injury.

When using more than one set of F3SJ-Bs, install them so that mutual

interference does not occur, such as by configuring series connections

or using physical barriers between adjacent sets.

Make sure that the F3SJ-B is securely mounted and its cables

and connectors are properly secured.

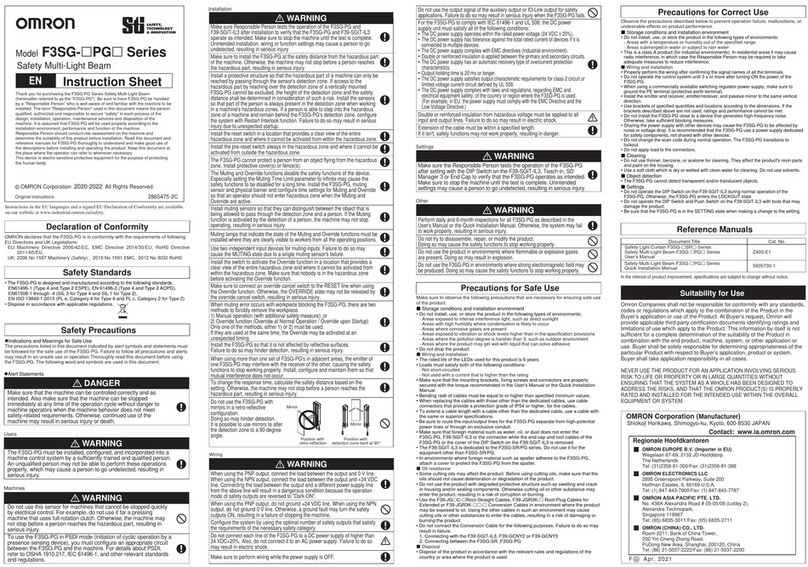

Do not use the sensor system with mirrors in a retro-reflective

configuration as shown below. Doing so may hinder detection. It is

possible to use mirrors to "bend" the detection zone to a 90-degree angle.

Connect the load between the output and 0V line (PNP output). Connecting

the load between the output and +24 V line will result in a dangerous

condition because operation is reversed to "ON when blocked".

Do not short-circuit the output line to the +24 V line. Otherwise, the output

is always ON. Also, the 0 V of the power supply must be grounded so

that output does not turn ON due to grounding of the output line.

Configure the system by using the optimal number of safety outputs

that satisfy the requirements of the necessary safety category.

Make sure to perform wiring while the power supply is OFF.

Do not connect each line of F3SJ-B to a DC power supply of more than

24 VDC+20%.Also, do not connect to an AC power supply. Failure to

do so may result in electric shock or breakdown of the device.

Do not use the auxiliary output for safety applications.A person may go

undetected even if F3SJ-B is out of order, resulting in serious injury.

Double or reinforced insulation from hazardous voltage must be applied

to all input and output lines. Failure to do so may result in electric shock.

Do not try to disassemble, repair, or modify this product. Doing so

may cause the safety functions to stop working properly.

Do not use the F3SJ-B in environments where flammable or

explosive gases are present. Doing so may result in explosion.

Perform daily and 6-month inspections for the F3SJ-B. Otherwise,

the system may fail to work properly, resulting in serious injury.

Do not use radio equipment such as cellular phones, walkie-talkies,

or transceivers near the F3SJ-B.

Extension of the cable must be within a specified length. If it isn't,

safety function may not work properly, resulting in danger.

To use the F3SJ-B in PSDI mode (Reinitiation of cyclic operation by

the protective equipment), you must configure an appropriate circuit

between the F3SJ-B and the machine. For details about PSDI, refer

to OSHA1910.217, IEC61496-1, and other relevant standards

and regulations.

For the F3SJ-B to comply with IEC61496-1 and UL508, the DC power

supply unit must satisfy all of the following conditions:

• Must be within the rated power voltage (24 V DC ± 20%)

• Must have tolerance against the total rated current of devices if it is

connected to multiple devices

• Must comply with EMC directives (industrial environment)

• Double or reinforced insulation must be applied between the primary

and secondary circuits

• Automatic recovery of overcurrent protection characteristics

• Output holding time must be 20ms or longer

• Must satisfy output characteristic requirements for class 2 circuit or

limited voltage current circuit defined by UL508

• Must comply with laws and regulations, regarding EMC and electrical

equipment safety, of the country or region where the F3SJ-B is used

(Ex: In EU, the power supply must comply with the EMC Directive

and the Low Voltage Directive.)

Perform an inspection for all F3SJ-B as described in

"Chapter 5 Checklists" in the User's Manual.

WARNING

WARNING

WARNING

For Installation

For Wiring

Other

Reflector

Position with retro-reflection Position with detection zone

bent at 90°

Reflector

Install muting sensors so that they can distinguish between the object that

is being allowed to be passed through the detection zone and a person. If

the muting function is activated by the detection of a person, it may

result in serious injury.

Use two independent input devices for muting inputs.

The muting and override functions disable the safety functions of the

device.You must ensure safety using other method when these functions

are operating.A switch to activate the override function must be a

hold-to-run device such as a spring return key switch and must be

installed in a location that provides a clear view of the entire hazardous

zone and where it cannot be activated from within the hazardous

zone.Make sure that nobody is in the hazardous zone before activating

the override function.

Make sure to observe the following precautions that are necessary for

ensuring safe use of the product.

• Do not install the F3SJ-B in the following types of environments:

-Areas exposed to intense interference light, such as direct sunlight

-Areas with high humidity where condensation is likely to occur

-Areas where oil mist or corrosive gases are present

-Areas exposed to vibration or shock levels higher than in the specification

provisions

-Areas where the product may come into contact with water

-Areas with pollution degree 3

-Areas where the product may get wet with oil that can solve adhesive

• Loads must satisfy both of the following conditions:

-Not short-circuited

-Not used with a current that is higher than the rating

• Do not drop the product.

• Install the emitter and receiver to the same vertical direction.

• Dispose of the product in accordance with the relevant rules and regulations

of the country or area where the product is used.

• Make sure to tighten the connectors of the cables securely.

• When replacing the cable connectors with other types of connectors, use

connectors that provide a protection grade of IP54 or higher.

• Be sure to route the input/output lines for the F3SJ-B separate from

high-potential power lines or through an exclusive conduit.

• To extend a cable length with a cable other than the dedicated cable, use

cable with the same or superior specifications.

• The cable extension length must be within the specified length (30 m max).

• PC Setting Support Software "SD Manager" (F39-GWUM) and Setting

Console (F39-MC21) are available only for F3SJ-A series. Do not use these

F3SJ-B series.

• Do not apply excessive force to the cover. Do not keep using the product

with the cover displaced, and do not remove the cover.

• The product may be affected depending on the type of the cutting oil. Be

sure to perform checking before using it.

PRECAUTIONS FOR SAFE USE

OMRON Corporation (Manufacturer)

Contact: www.ia.omron.com

Regional Headquarters

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 JAPAN

OMRON EUROPE B.V. (Importer in EU)

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Apr, 2021

u

F

Emitter

Main

Circuit

Test Input Circuit

Interlock

Select Input Circuit

Reset Input Circuit

Indication

Receiver

Main

Circuit 2

External Device

Monitoring Input

Circuit

Indication

Receiver

Main

Circuit 1

Red Not used

Black Test input *1

Brown

White Not used.

Yellow Reset input

Load

Load

Load

■Wiring to disable external device monitoring function on the

Basic System

Short-circuit the external device monitoring input to the auxiliary

output.

Yellow

Auxiliary output

Red External device monitoring input

■Wiring for external device monitoring function on the Basic System

Brown

Blue

Shield

Red External device

monitoring input

Gray

White Safety output 2

Black Safety

output 1

*

1 Emission is stopped : Short-circuited to Vs-3 V to Vs.

Normal operation : Short-circuited to 0 V to 1/2 Vs or open.

Yellow Auxiliary

output

Blue

Shield 0 V

+24V

5 6

5 6

Gray

Communication

line (–)

Pink

Pink

Communication

line (+)

1

2

3

4

8

7

2

8

1

3

4

7

8

4

SAFETY LIGHT CURTAIN

INSTRUCTION SHEET

Emitter Receiver

15. Bottom-beam-state indicator (Blue)

8. Muting input 2 indicator (Green)

7. Muting input 1 indicator (Green)

6. Muting error indicator (Green)

5. Test indicator (Green)

4. Power indicator (Green)

3. Lockout indicator (Red)

2. ON/OFF-state indicator (Green/Red)

1. Stable-state indicator (Green)

14. Top-beam-state indicator (Blue)

3. Lockout indicator (Red)

2.

ON/OFF-state indicator (Green/Red)

1. Stable-state indicator (Green)

14. Top-beam-state indicator (Blue)

15.

Bottom-beam-state indicator (Blue)

13. External device monitoring

indicator (Green)

12. Not used

11. Internal error indicator (Red)

10. Configuration indicator (Green)

9. Communication indicator (Green)

Instructions in the EU languages and a signed EU Declaration of Conformity

are available on our website at www.industrial.omron.eu/safety.

LEGISLATION AND SAFETY STANDARDS

OMRON declares that the F3SJ is in conformity with the requirements of

following EU Directives and UK Legislations:

EU: Machinery Directive 2006/42/EC, EMC Directive 2014/30/EU, RoHS Directive

2011/65/EU,

UK: 2008 No 1597 Machinery (Safety) , 2016 No 1091 EMC, 2012 No 3032 RoHS