Table of Contents

1. Related Manuals........................................................................................ 1

2. Terms and Definitions............................................................................... 2

3. Precautions................................................................................................ 3

4. Overview .................................................................................................... 4

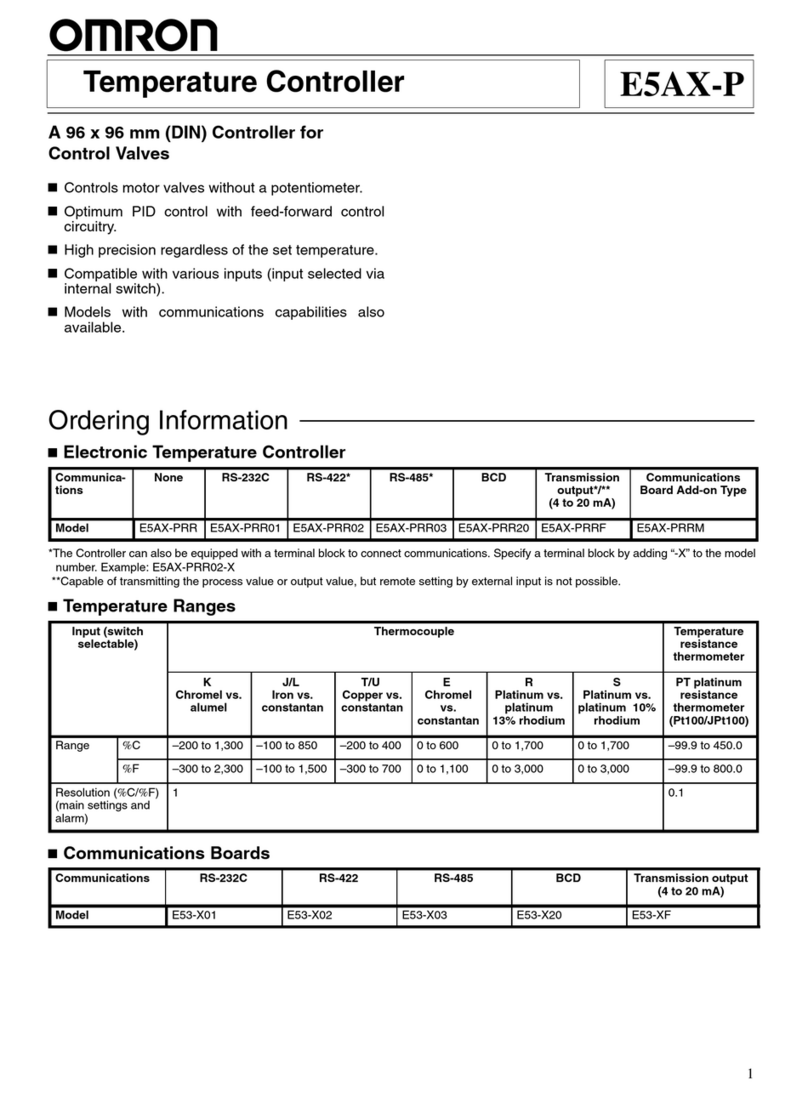

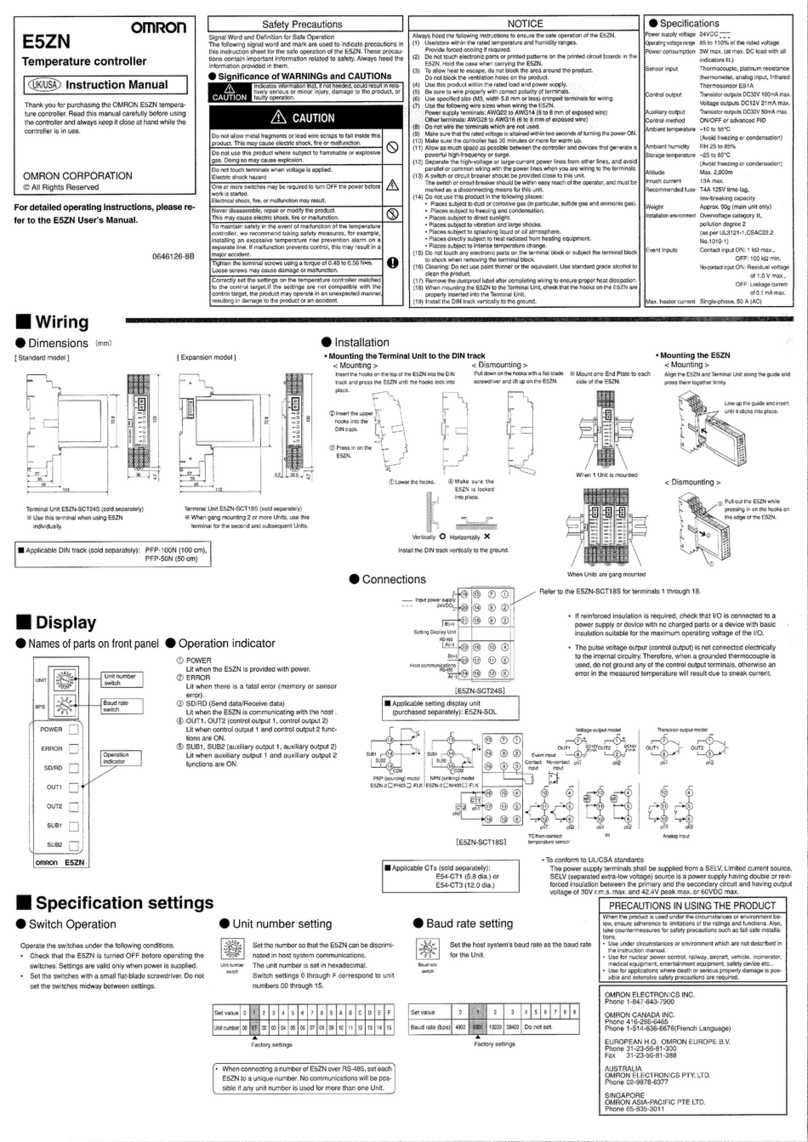

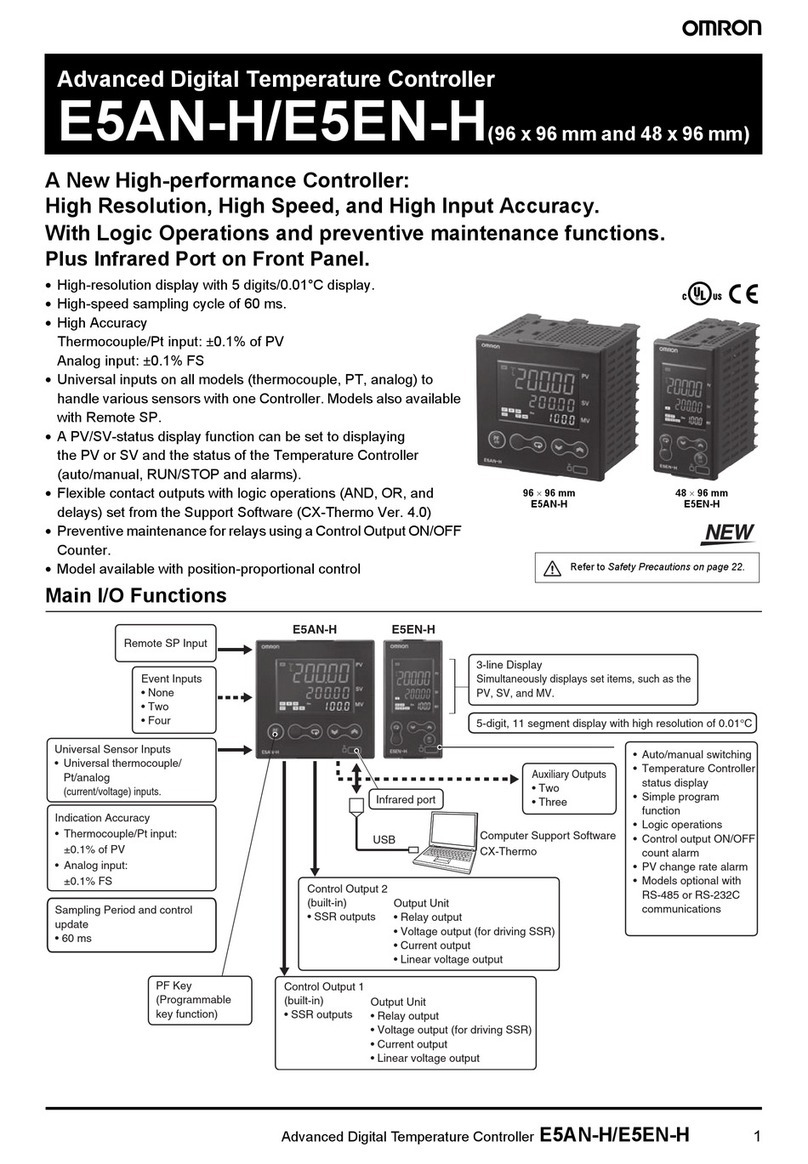

5. Applicable Devices and Device Configuration ....................................... 5

5.1. Applicable Devices............................................................................. 5

5.2. Device Configuration.......................................................................... 7

6. Serial Communications Settings ............................................................. 9

6.1. Parameters ........................................................................................ 9

6.2. Cable Wiring .................................................................................... 10

7. Serial Communications Connection Procedure ....................................11

7.1. Work Flow.........................................................................................11

7.2. Digital Temperature Controller Setup............................................... 13

7.3. PLC Setup........................................................................................ 17

7.4. Serial Communication Status Check................................................ 38

8. Initialization Method................................................................................ 44

8.1. Initializing a PLC .............................................................................. 44

8.2. Initializing a Digital Temperature Controller...................................... 45

9. Program.................................................................................................... 46

9.1. Overview.......................................................................................... 46

9.2. Communications Sequence............................................................. 51

9.3. Error Detection Processing.............................................................. 52

9.4. Memory Maps .................................................................................. 53

9.5. Ladder Program............................................................................... 56

9.6. Protocol Data ................................................................................... 62

9.7. Timing Charts................................................................................... 73

9.8. Error Processing .............................................................................. 74

10. Revision History .................................................................................. 77