E5jJE5jJ

4

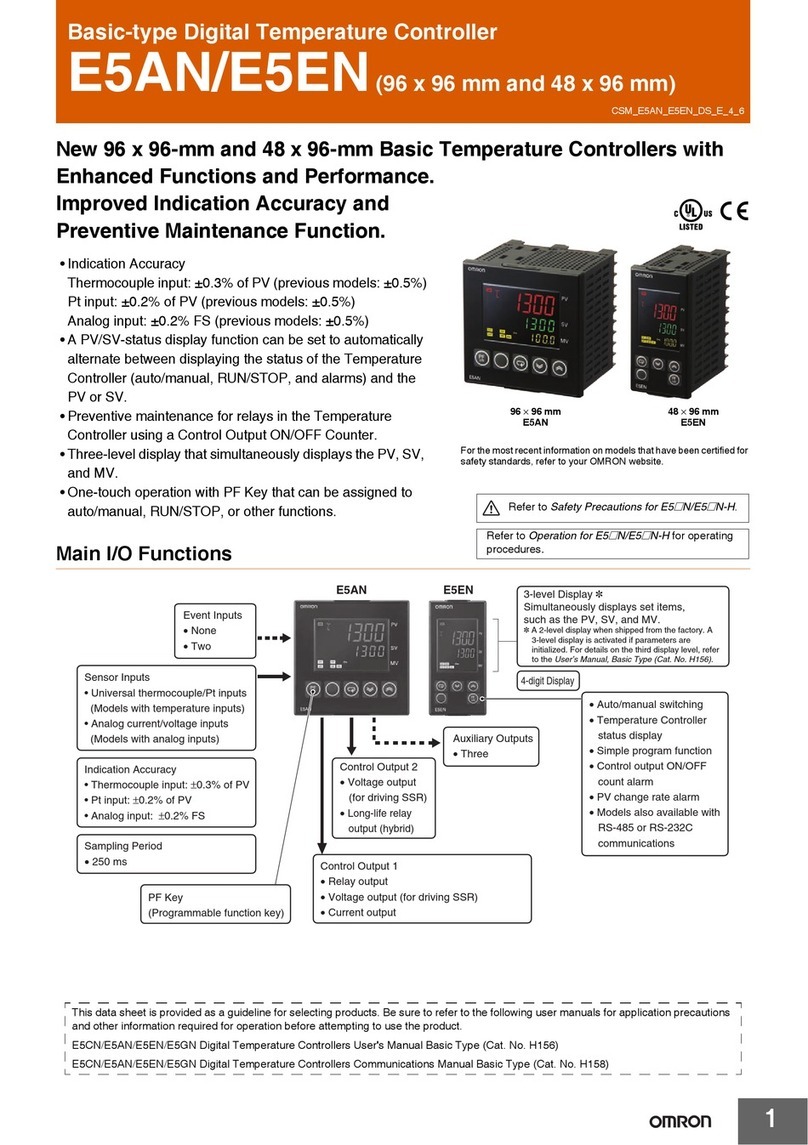

Characteristics

Indication

accuracy (see note 1)

(±

0.5% of indication value or

±1°

C, whichever greater)

±

1 digit max.

Hysteresis 0.1°

to 999.9

°C/°

F (in units of 0.1

°C/°

F) (during ON/OFF control action)

Proportional band

0.1°

to 999.9

°C/°

F (in units of 0.1

°C/°F)

Integral (reset) time

0 to 3,999 s (in units of 1 s)

Derivative (rate) time

0 to 3,999 s (in units of 1 s)

Alarm output setting range

Thermocouple (K/J/L/N): –1,999

°

to 9,999

°C/°

F (in units of 1

°C/°F)

Platinum resistance thermometer

, thermocouple (T/U): –199.9

°

to 999.9

°C/°F

(in units of 0.1

°C/°F)

Control period

Pulse output: 1 to 99 s (in units of 1 s)

Sampling period

500 ms

Output refresh time

500 ms

Display refresh time 500 ms

Insulation resistance (see note 2)

20 M

Ω

min. (at 500 VDC)

Dielectric strength

2,000 V

AC, 50/60 Hz for 1 min between terminals of dif

ferent polarities

V

ibration resistance

Malfunction:

10 to 55 Hz, 9.8 m/s

2

(1G) for 10 min each in X, Y, and Z directions

Destruction:

10 to 55 Hz, 19.6 m/s

2

(2G) for 2 hrs each in X, Y

, and Z directions

Shock resistance

Malfunction:

196 m/s

2

(20G), 3 times each in 6 directions

(98 m/s

2

(10G) applied to the relay)

Destruction:

294 m/s

2

(30G), 3 times each in 6 directions

Life expectancy

Mechanical:

10,000,000 operations (relay alarm output)

Electrical:

100,000 operations (relay alarm output)

Ambient temperature

Operating: –10°

C to 55

°

C (with no icing)

Storage: –25°

C to 65

°

C (with no icing)

Ambient humidity

Operating: 35% to 85%

Memory protection

Non-volatile memory (number of write operations: 100,000)

Enclosure ratings

Front panel:

E5AJ/E5EJ/E5BJ: IEC standard IP54

E5CJ: IEC standard IP50 (see note 3)

Rear case:

IEC standard IP20

Terminals:

IEC standard IP00

Weight

E5AJ: Approx. 360 g, E5EJ: Approx. 280 g, E5BJ: Approx. 240 g, E5CJ: Approx. 170 g;

Mounting adapter for E5CJ: approx. 10 g;

Mounting bracket for E5AJ, E5BJ, and E5EJ: Approx. 65 g

EMC Emission Enclosure: EN55011 Group 1 class A

Emission AC Mains:

EN55011 Group 1 class A

Immunity ESD:

EN61000-4-2:

4-kV contact discharge (level 2)

8-kV air discharge (level 3)

Immunity RF-interference:

ENV50140:

10 V/m (amplitude modulated,

80 MHz to 1 GHz) (level 3)

10 V/m (pulse modulated, 900 MHz)

Immunity Conducted Disturbance:

ENV50141:

10 V (0.15 to 80 MHz) (level 3)

Immunity Burst:

EN61000-4-4:

2-kV power-line (level 3)

2-kV I/O signal-line (level 4)

Approved standards

UL1092, CSA C22.2 No. 142

Conforms to EN50081-2, EN50082-2, EN61010-1 (IEC1010-1) (see note 4)

Conforms to VDE0106/part 100 (Finger Protection), when the separately-ordered terminal

cover is mounted.

Note: 1. The

indication accuracy of the K, T

, and N thermocouples at a temperature of –100

°

C or less is

±2°C±

1 digit maximum. The indica

-

tion

accuracy of the U thermocouple at any temperature is

±2°C±

1 digit maximum.

2.

The insulation resistance was measured with a Control Output Unit attached.

3.

The model numbers of the exclusive watertight covers conforming to IP66, NEMA4 are as follows:

For E5AJ: Y92A-96N; For E5BJ: Y92A-72N; For E5CJ: Y92A-48N; For E5EJ: Y92A-49N

4.

Basic insulation is between the input and output.