I-134 Modular Temperature Controller E5ZN

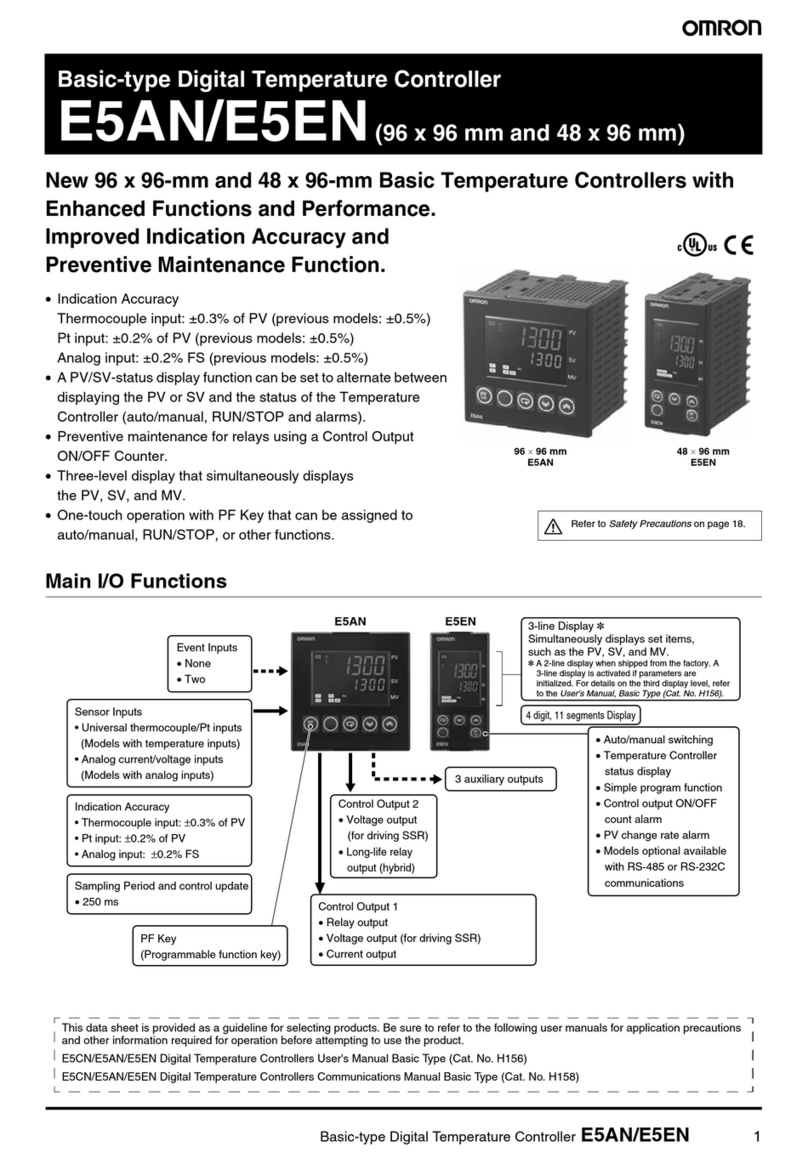

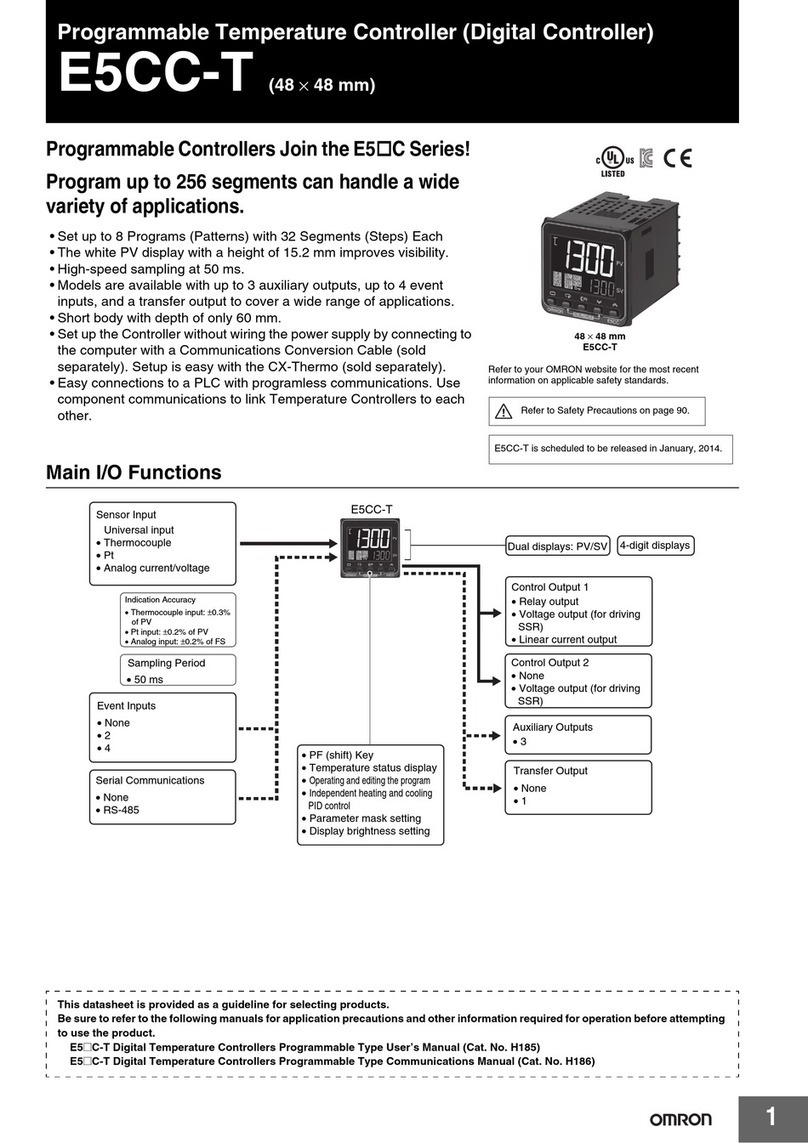

Nomenclature

E5ZN-2

E5ZN-SDL

The following diagram shows the names and functions of the E5ZN-SDL parts for when it is connected to the E5ZN-2@@@@@@@.

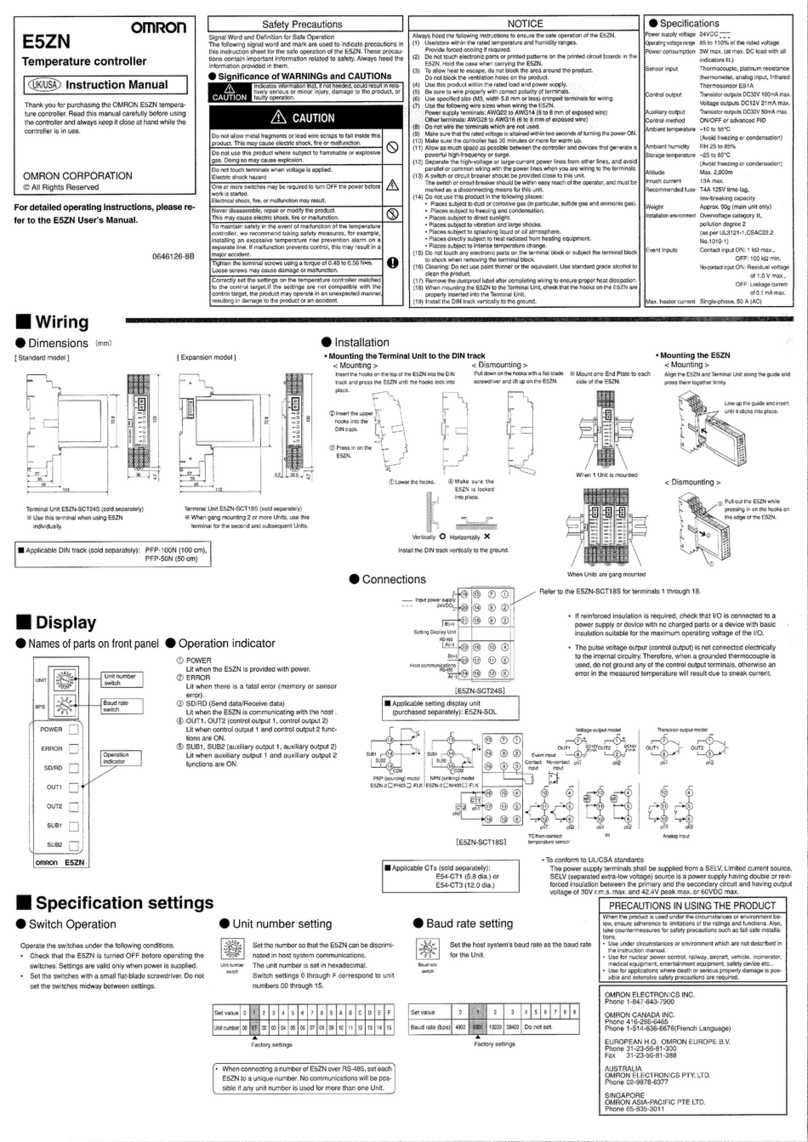

Operation Indicators

POWER

Lights when power is turned ON.

ERROR

Lights when a fatal error (e.g., memory

error or sensor error) occurs.

SD/RD (Communications Operation)

Flashes during communications with the host.

OUT1 (Control Output 1)

Lights when the control output 1 is ON.

OUT2 (Control Output 2)

Lights when the control output 2 is ON.

SUB1 (Auxiliary Output 1)

Lights when the auxiliary output 1 is ON.

SUB2 (Auxiliary Output 2)

Lights when the auxiliary output 2 is ON.

POWER

ERROR

SD/RD

OUT1

OUT2

SUB1

SUB2

Unit Number Setting

Setting range of 0 to F allows up

to 16 Units to be set.

Baud Rate

No. 1 Display

Displays the PV or the type of

setting data.

No. 2 Display

Displays the target value, the

control variable, or the set value

for setting data (setting contents).

Up Key

Each time this key is pressed, the

value displayed in No. 2

Display increases. If it is held

down, the rate of increase

becomes faster.

It can also be used to move to the

next setting item.

Down Key

Each time this key is pressed, the

value displayed in No. 2

Display decreases. If it is held

down, the rate of decrease

becomes faster.

It can also be used to return to the

previous setting item.

Channel Key

Press this key to change the

channel number.

Copy Key

Press this key to read all the

settings from the Temperature

Controller to the Setting Display

Unit, or to write from the Setting

Display Unit to the Temperature

Controller.

UNIT Key

Press to switch the unit number.

Level Key and Mode Key

Press together to switch to protect mode.

Mode Key

Press this key to switch setting

data within the setting level.

Level Key

Press this key to switch setting

levels.

Unit/Channel Indicator

Indicates the unit number and

the channel number.

• SUB3 (Auxiliary Output 3)

Pulse output models: Always not lit.

Analog output models: Not lit when the

auxiliary output drops to 0% or lower.

Lit when the auxiliary output is above 0%.

• CMW (Communications Write Control)

Lights when communications write is permitted

and remains unlit when it is prohibited.

• STOP

Lights when operation stops. Lights for an

event or when RUN/STOP is set to STOP

during control. Remains unlit at other times.

• SUB1, SUB2 (Auxiliary Output 1, Auxiliary

Output 2)

Light when the auxiliary output 1 or the

auxiliary output 2 functions are ON.

• OUT1, OUT2 (Control Output 1, Control

Output 2)

Light when the control output 1 or the control

output 2 functions are ON.

• These indicators indicate the terminal

operations for the E5ZN-2@@@@@@@.

Operation Indicators Temperature Unit

Displayed when the display unit for setting

data is temperature. The display is

determined by the setting for temperature unit,

with either “°C” or “°F” displayed accordingly.

• SUB4 (Auxiliary Output 4)

Pulse output models: Always not lit.

Analog output models: Not lit when the

auxiliary output drops to 0% or lower.

Lit when the auxiliary output is above 0%.