vii

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

3 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

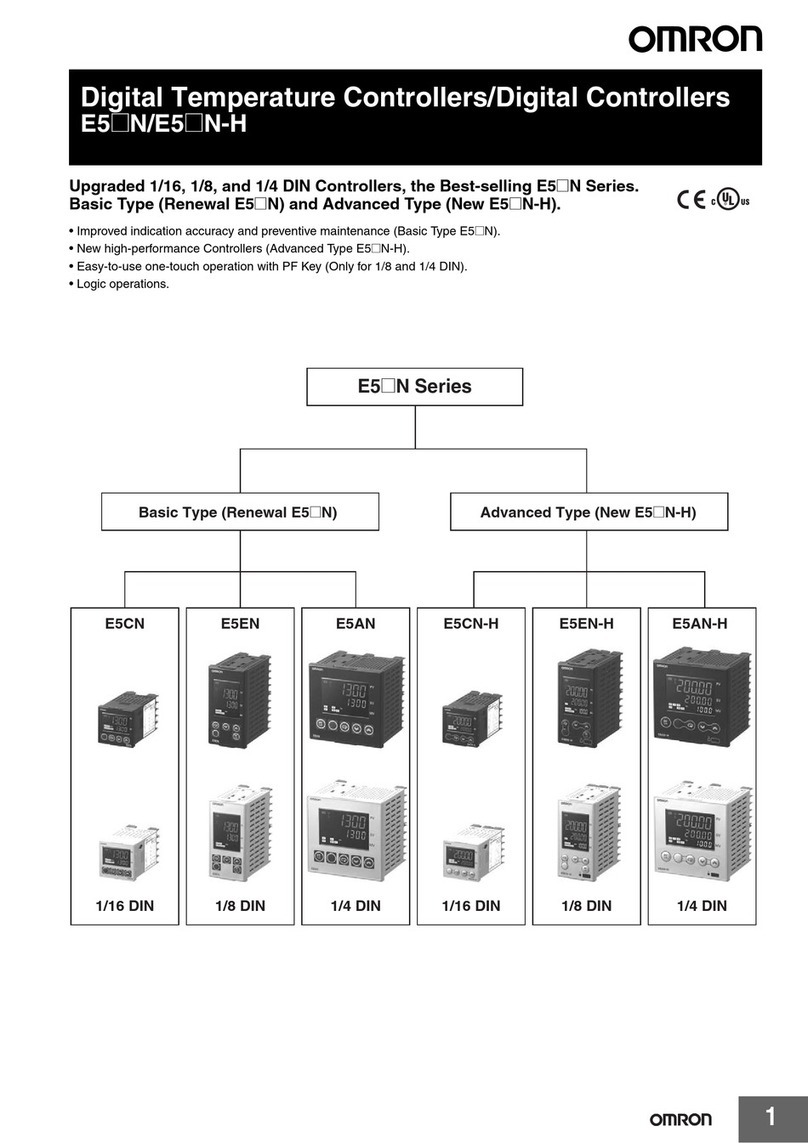

SECTION 1

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

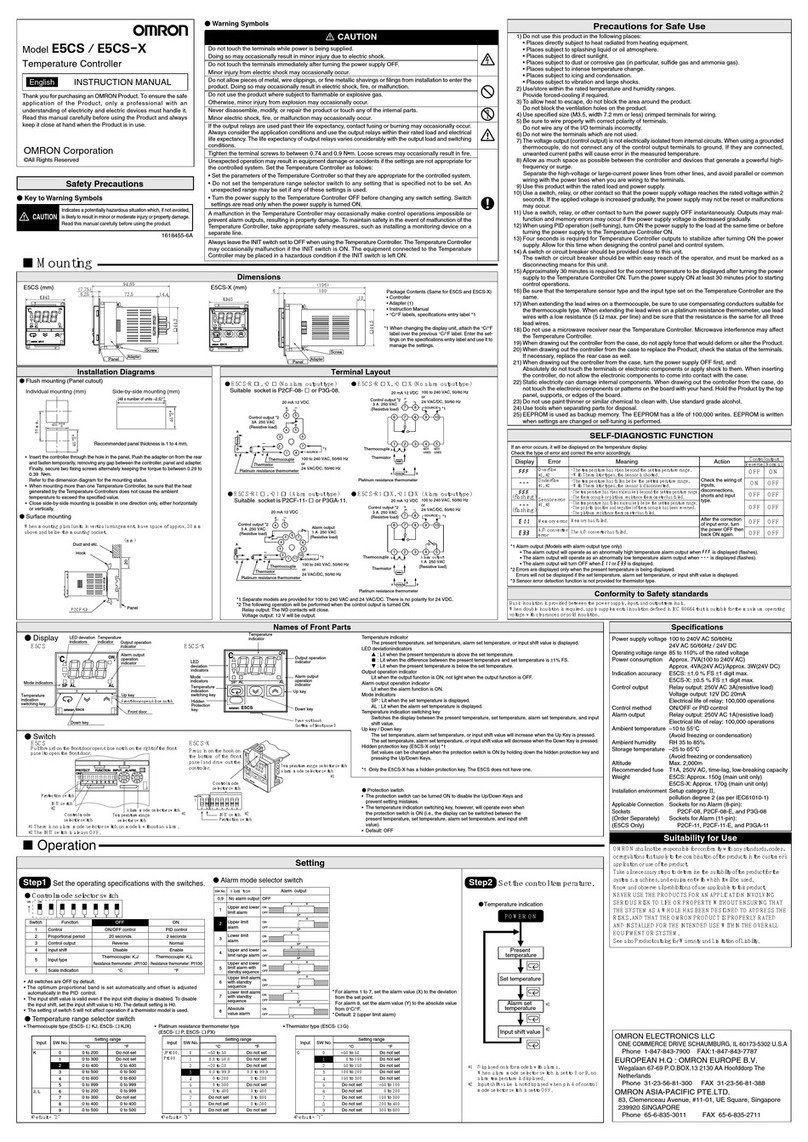

1-1 Name and Function of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 I/O Configuration and Main Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Using the I/O Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 3

Temperature Control Settings. . . . . . . . . . . . . . . . . . . . . 21

3-1 Setting the Input Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Selecting °Centigrade/°Farenheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-3 Selecting PID Control or ON/OFF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3-4 Setting Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-5 Setting the SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-6 Executing ON/OFF Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-7 Determining PID Constants: Autotuning and Manual Setup . . . . . . . . . . . . . . . . . 30

3-8 Alarm Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-9 Using Heater Burnout Alarm (HBA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-10 Starting and Stopping Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-11 Operating Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SECTION 4

Settings Used Only when Required. . . . . . . . . . . . . . . . . 39

4-1 Shifting Input Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-2 Alarm Hysteresis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-3 Setting Scaling Upper and Lower Limits (Analog Input). . . . . . . . . . . . . . . . . . . . 46

4-4 Executing Heating and Cooling Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-5 Using the Event Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-6 Setting the SP Upper and Lower Limit Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-7 SP Ramp Function: Limiting SP Change Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-8 Key Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-9 Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-10 Reading Temperatures for Multiple E5ZN Units . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-11 Remote PV Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57