2

To prevent the risk of damage to equipment, leave nothing around the motor

and driver that would obstruct ventilation.

Do not hold the output shaft of the motor and gearhead, as well as any of

the cables. Doing so may result in injury.

Do not touch the motor output shaft (key groove or pinion) with bare hands.

Doing so may result in injury.

When assembling the motor with the gearhead, exercise caution not to pinch

your ngers or other parts of your body between the motor and gearhead.

Injury may result.

Securely install the motor, gearhead and driver to their respective mounting

plates. Inappropriate installation may cause the motor, gearhead or driver to

detach and fall, resulting in injury or equipment damage.

Provide a cover over the rotating part (output shaft) of the motor or

gearhead. Failure to do so may result in injury.

When installing the motor or gearhead in the equipment, exercise caution

not to pinch your ngers or other parts of your body between the equipment

and motor or gearhead. Injury may result.

Securely install the load on the output shaft of the motor or gearhead.

Inappropriate installation may result in injury.

Do not shut o the negative side of the power supply during operation.

Also, note that the wiring for the power supply does not disconnect. Doing

so may cause damage to equipment.

Provide an emergency stop device or emergency stop circuit external to the

equipment so that the entire equipment will operate safely in the event of a

system failure or malfunction. Failure to do so may result in injury.

Immediately when trouble has occurred, stop operation and turn o the

driver power. Failure to do so may result in re, electric shock or injury.

Do not touch the rotating part (output shaft) during operation. This may

cause injury.

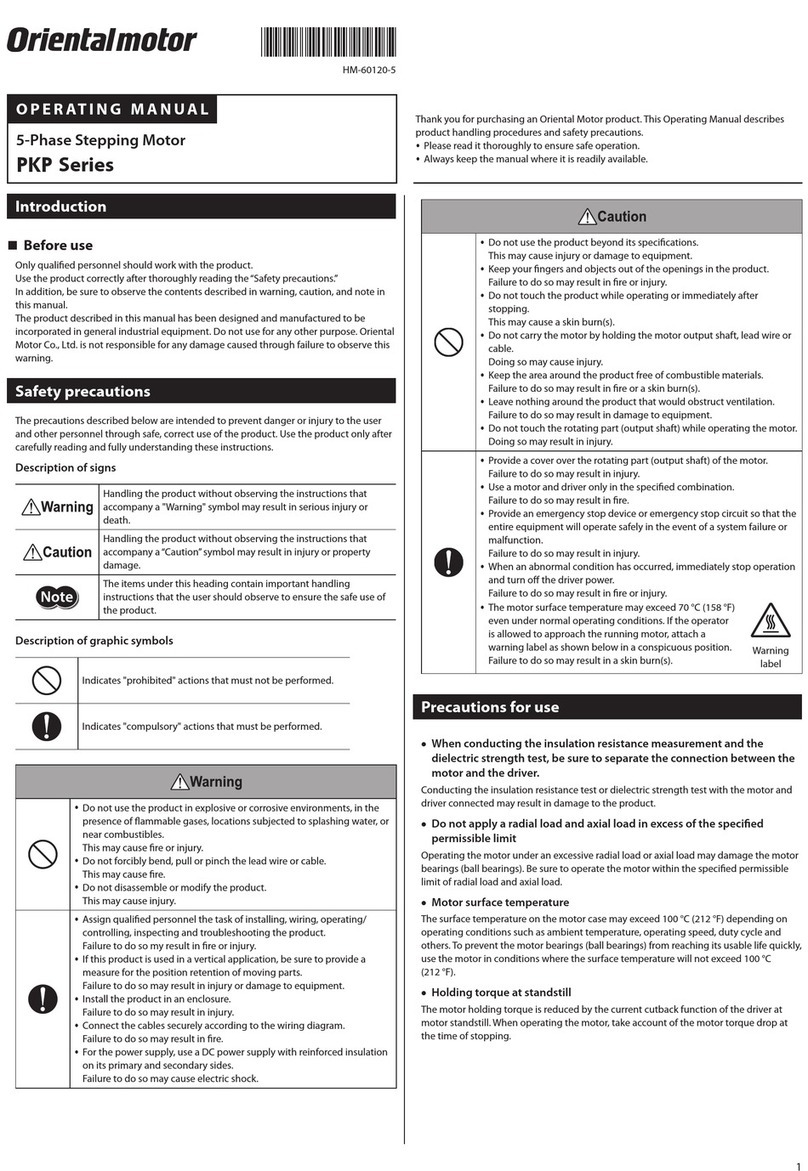

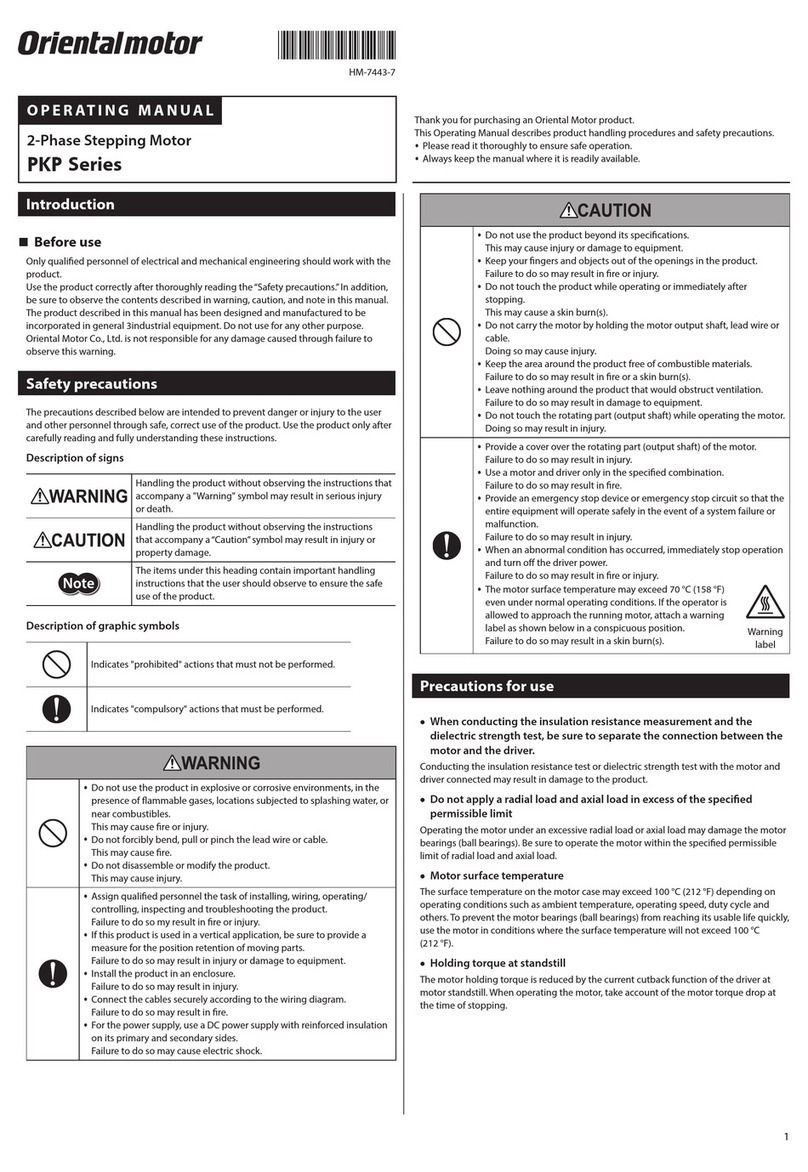

The motor surface temperature may exceed 70 °C (158 °F)

even under normal operating conditions. If the operator

is allowed to approach the motor in operation, attach a

warning label in a conspicuous position as shown in the

gure. Failure to do so may result in a skin burn(s). Warning label

Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

Precautions for use

Regeneration energy

When using the motor in operation such as vertical drive (gravitational

operation) or sudden starting/stopping of an inertial load, regeneration energy

may generate. Since the driver has no function to consume regeneration

energy, if the output capacity or overvoltage allowance of the DC power

supply is small, the protective function for the power supply or driver may

activate, and the motor may stop. When performing these operations, use a

DC power supply or battery that has a large output capacity or overvoltage

allowance. Also, use an electromagnetic brake motor not to drop the moving

part in vertical drive (gravitational operation).

If the protective function for the power supply or driver is activated, contact

your nearest Oriental Motor sales oce.

Do not conduct the insulation resistance measurement or dielectric

strength test with the motor and driver connected

Conducting the insulation resistance measurement or dielectric strength test

with the motor and driver connected may result in damage to the product.

Do not use a solid-state relay (SSR) to turn on/o the power

A circuit that turns on/o the power via a solid-state relay (SSR) may damage

the motor and driver.

Notes for power ON/OFF using a mechanical contact

When turning on or o the power supply using a mechanical contact (breaker,

electromagnetic switch, relay, etc.), do so only the positive side (+) of the

power supply using the mechanical contact. Turning on or o the positive

side (+) and the negative side (-) of the power supply simultaneously using

a mechanical contact may cause damage to the control circuit or peripheral

equipment.

Refer to USER MANUAL Basic Function for details.

Note on connecting a power supply whose positive terminal is

grounded

The driver's main power supply input terminal (CN1), I/O signal connector

(CN4), communication connector (CN5/CN6/CN7) and control power supply

input terminal (TB1) are not electrically insulated. When grounding the

positive terminal of the power supply, do not connect any equipment (PC,

etc.) whose negative terminal is grounded. Doing so may cause the driver and

these equipment to short, damaging both.

Preventing electrical noise

Refer to USER MANUAL Basic Function for measures with regard to noise.

Grease measures

On rare occasions, grease may ooze out from the gearhead. If there is concern

over possible environmental damage resulting from the leakage of grease,

check for grease stains during regular inspections. Alternatively, install an

oil pan or other device to prevent leakage from causing further damage. Oil

leakage may lead to problems in the customer’s equipment or products.

Note on using in low temperature environment

When an ambient temperature is low, a load torque may increase due to the

oil seal or viscosity of grease used in the gearhead, and the output torque

may decrease or an overload alarm may generate. However, as time passes,

the oil seal or grease is warmed up, and the motor can be operated without

generating the overload alarm.

Apply grease to the output shaft of a hollow shaft at gearhead

If you are using a hollow shaft at gearhead, apply grease (molybdenum

disulde grease, etc.) on the surface of the load shaft and inner walls of the

hollow output shaft to prevent seizure.

The driver uses semiconductor elements. Handle the driver with

care

The driver uses parts that are sensitive to electrostatic charge. Before touching

the driver, turn o the power to prevent electrostatic charge from generating. If

an electrostatic charge is impressed on the driver, the driver may be damaged.

Use a connection cable (included) when extending the wiring

distance between the motor and driver

Sliding noise of electromagnetic brake

An electromagnetic brake motor may cause a sliding noise of the brake disk

during operation. There is no functional problem.

Preparation

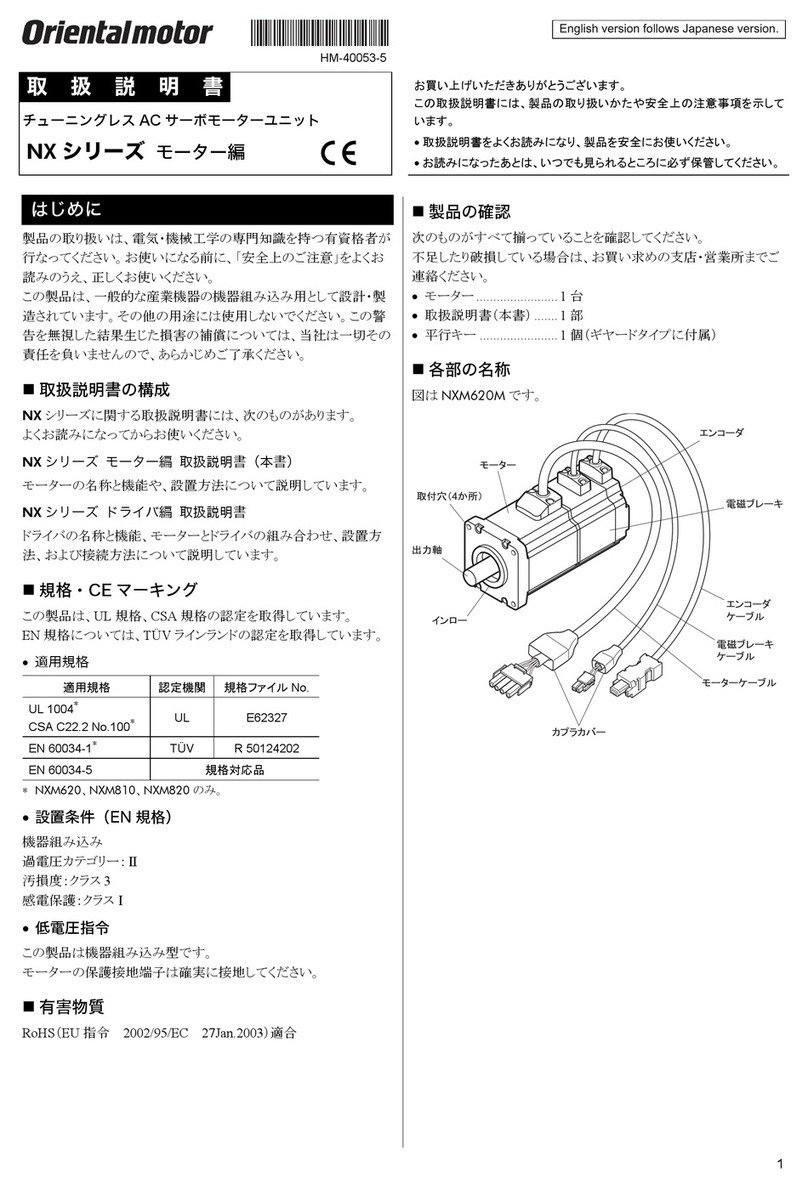

Checking the product

Verify that the items listed below are included. Report any missing or

damaged items to the branch or sales oce from which you purchased the

product.

Motor (with a gearhead, only for combination type) ............1 unit

Driver .....................................................................................1 unit

Connection cable ....................................................................1 pc.

CN1 connector ......................................................................1 pc.

OPERATING MANUAL (this document) .............................1 copy

Accessories for combination type

Hexagonal socket head screw set ........................................................1 set

Parallel key .........................................................................................1 pc.

(Secured to the gearhead output shaft on the parallel shaft gearhead)

Safety cover ........................................................................................1 pc.

(Included with the hollow shaft at gearhead)

Safety cover mounting screw .............................................................. 2 pcs.

(Included with the hollow shaft at gearhead)

Combinations of motors and drivers

Verify the model number of the purchased unit against the number shown on

the package label. Check the model number of the motor and driver against

the number shown on the nameplate.

in the model names indicates a number representing the gear ratio.

indicates a number representing the length of a connection cable.

The combination types come with the motor and gearhead pre-assembled.

zStandard type

Combination type parallel shaft gearhead

Unit model Motor model Gearhead

model Driver model

BLV620KS-BLVM620K-GFS GFS6GBLVD20KM

BLV640NS-BLVM640N-GFS BLVD40NM

Combination type hollow shaft at gearhead

Unit model Motor model Gearhead

model Driver model

BLV620KF-BLVM620K-GFS GFS6GFR BLVD20KM

BLV640NF-BLVM640N-GFS BLVD40NM

Round shaft type

Unit model Motor model Driver model

BLV620KA-BLVM620K-A BLVD20KM

BLV640NA-BLVM640N-A BLVD40NM