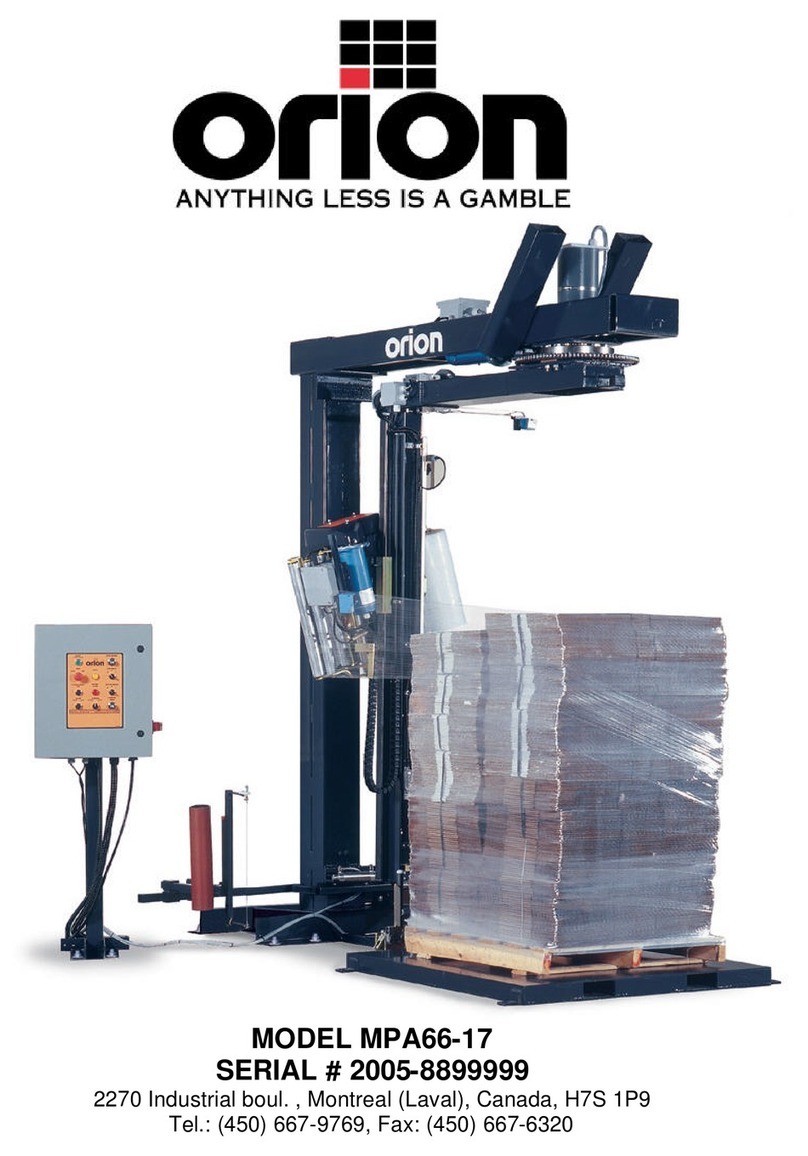

5

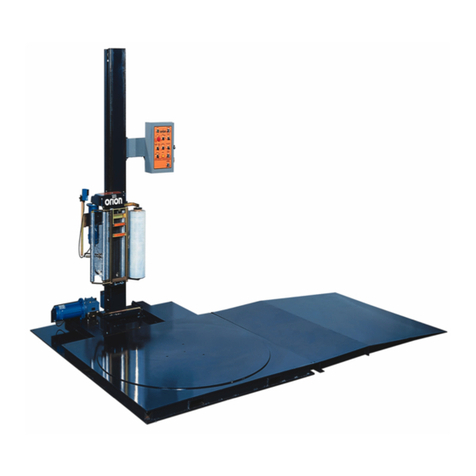

MACHINE UNLOADING

INSPECTION & INSTALLATION

UNLOADING

Machine can be easily unloaded and transported by a

forklift with a minimum capacity of 2500 lbs.

1. Carefully insert the forks into the lifting tubes to the

maximum possible depth. Depending on the model, a

forklift access may be either at the turntable end of the

machine frame, the tower end or both. In case of the

mongoose machine enter the forks under the frame or

insert the forks in the tube brackets welded to the top of

the machine.

2. Lift the machine (or other part of system) only to the

necessary height to move it with no bouncing or friction on

the floor.

3. Sit the machine down assuring uniform contact with the

floor, which is necessary to ensure correct and smooth

operation.

INSPECTION

1. Remove all packing and supporting additions - these

may include the blocks under the carriage and the

restraining bar over the table.

NOTE: when removing the stretchwrap film covering the

machine, care must be taken not to cut any of the

electrical wires and/ or polyurethane covering on the film

carriage rollers.

2. Perform a visual inspection of the electrical and

mechanical parts for loosened joints and / or broken

connections. Any suspected shipping damage must be

reported immediately to the freight carrier. Any transport

damage cannot be claimed to Orion Packaging Inc.

Items that are vulnerable to damage and must be

inspected are as follows:

- Motors and transmissions

- Junction boxes

- Electrical conduits

- Proximity and limit switches

- Photocells

3. Check under the turntable to ensure that there is no

crippling of the movable parts i.e. casters, center axle or

drive assembly.

4.Verify the following:

- Turntable or rotary arm drive system to confirm that the

reducer to drive the chain is snug and properly aligned.

- Verify the wires tight conduits for crushed sections or

loose fittings.

- Verify the film carriage to be sure that it is correctly

aligned with the tower

- Verify the tension on the lift chain.

- Verify all the dials and knobs on the control panel for

smooth action.

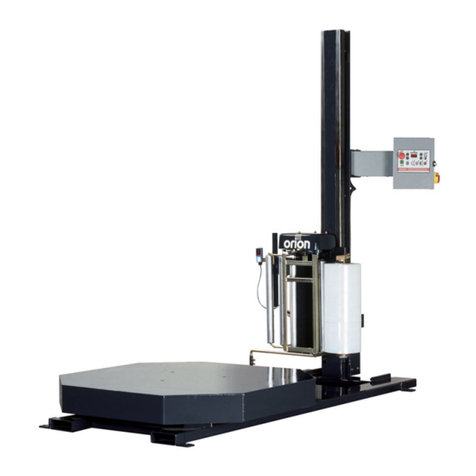

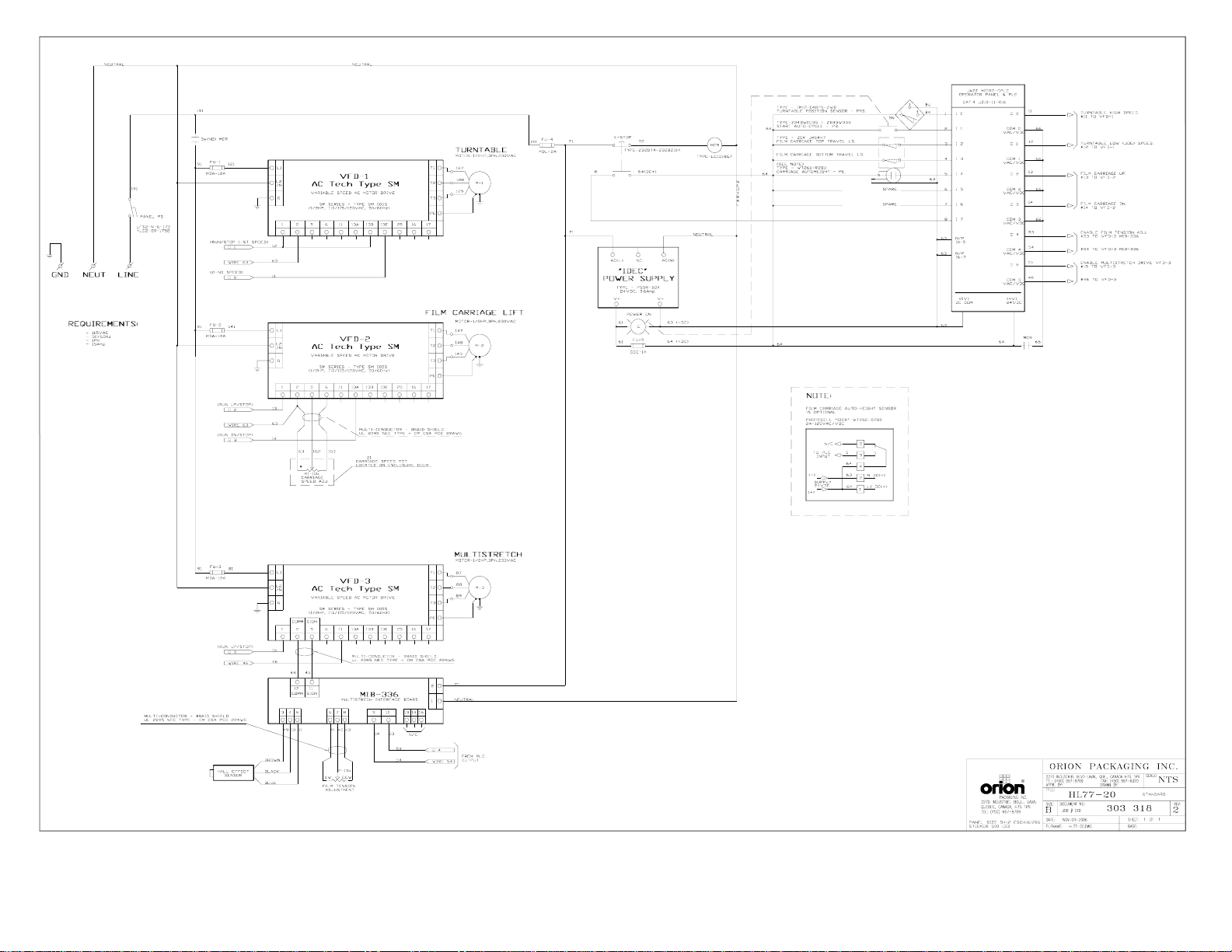

MACHINE INSTALLATION

After the visual inspection has been completed, the

electrical power and the compressed air shall be

connected as specified on the diagrams supplied with the

machine. An electrical diagram is provided with each

machine in the envelope attached to the panel box.

ASSEMBLY PROCEDURE

The structural frames of the machine have to be installed

on a leveled floor. Locate the main wrapper section into its

final position, keeping the tower assembly* away from any

traffic. The wrapper mainframe section must be bolted to

the floor by the 1/2” concrete floor anchors (leg &

shield or expandable type).

Any wiring that has been disconnected to facilitate

transport is marked with a number located on the junction

box to which the wiring must be reconnected. Any wire run

that appears too short or long may indicate that the

position of the mechanical components is incorrect. Verify

the status of all assemblies before proceeding.

* The tower deviation from vertical must not exceed 1/4”

on the distance of 10 feet (angle: 0 degrees 6’).

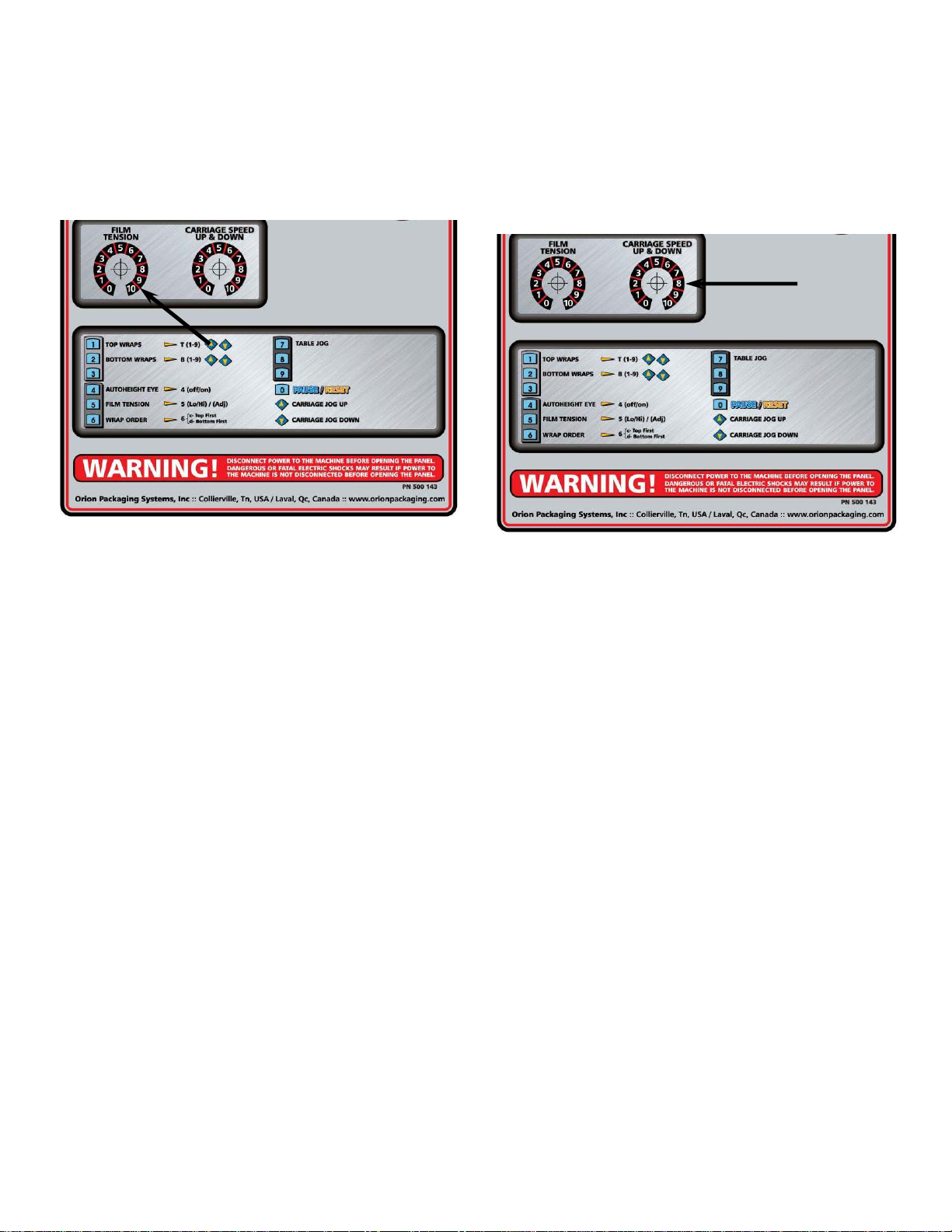

CONTROL PANEL

In the case of the free standing panel (console) place it

adjacent to the system and anchor firmly to the floor.

Connect the liquid tight (rigid conduit) to the main junction

box located on the wrapper main frame next to the tower.

Before Starting Machine Operation

Verify that the machine is properly connected to the

electrical source. The electrical requirements depend on

the machine type and features. For this information,

please see the machine electrical diagram provided with

the machine operation manual. The control panel layout

for the machine is shown on the drawing.

CAUTION: Before preceding the machine operation

familiarize yourself with the EMERGENCY-STOP button

and all functions, switches and pushbuttons.