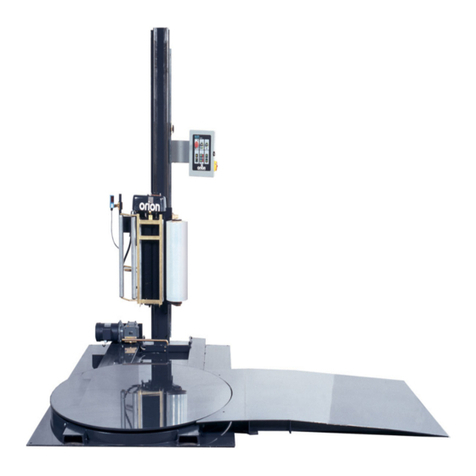

ORION PACKAGING SYSTEMS INC.

SEMI-AUTOMATIC SPECIFICATIONS

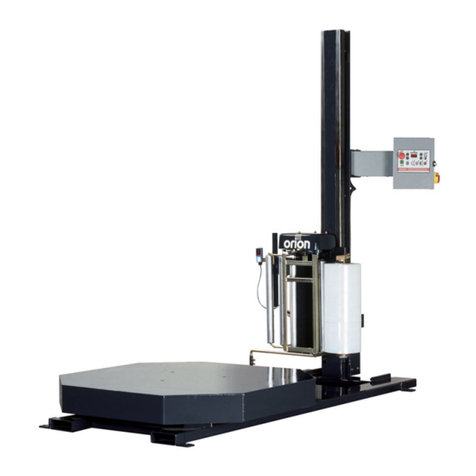

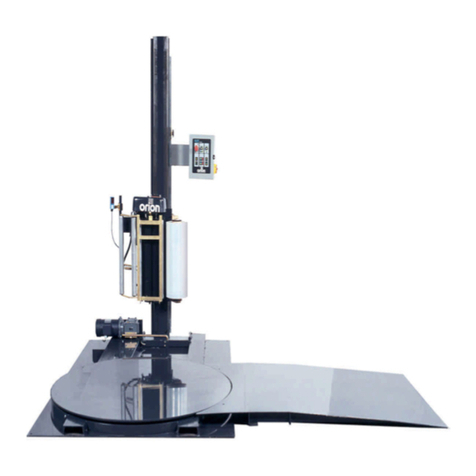

ORION EPIC®SERIES MODEL L-77

Spiral Semi-Automatic Medium Duty Low Profile

Maximum Load Size 55”W x 55”L x 84”H

Weight Capacity 4,000 Ibs. Dynamic, 20,000 Ibs. Static

Utilities 115 / 1 / 60 ; 15 Amp Service

Turntable 59” Diameter Structural Steel Plate

Dura-Glide™Turntable Support System

Quiet in Operation, Maintenance Free

3” Height Floor to Top of Turntable

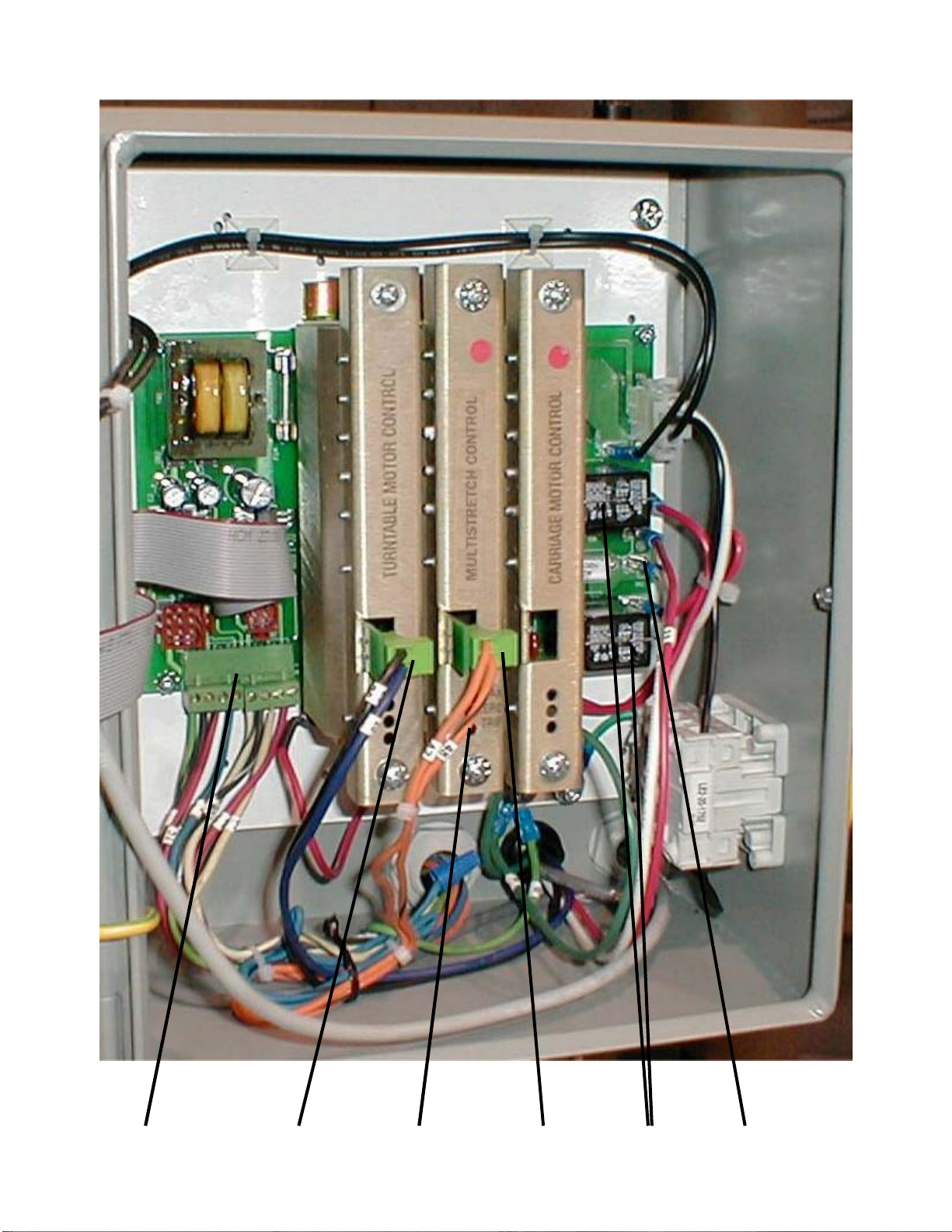

Turntable Drive 0-12 RPM Variable Turntable Speed

Variable Speed Drive Motor

Heavy Duty Chain Drive with Tensioner

Electronically Adjustable Acceleration/Deceleration (Soft Start)

Positive Alignment Feature

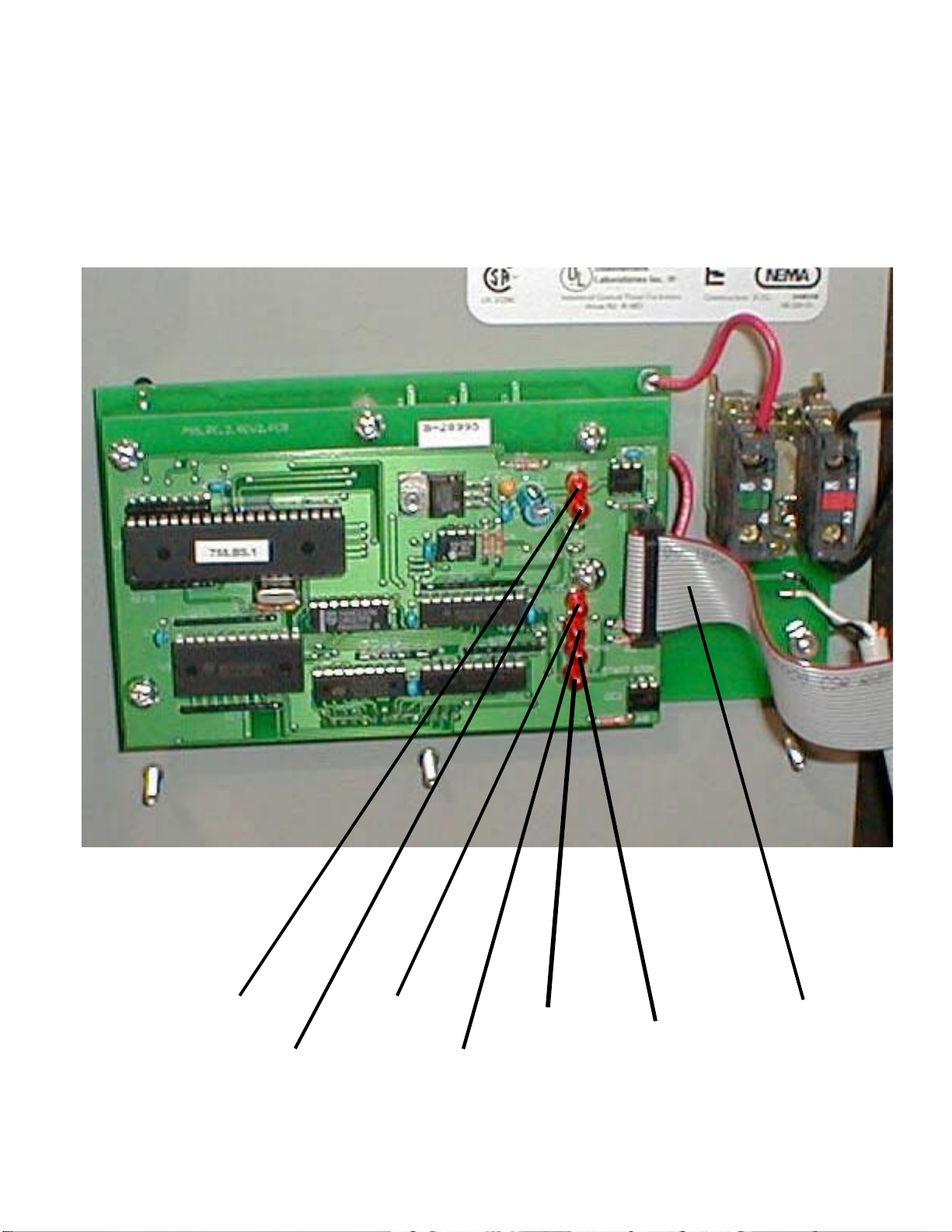

Control Features CSA Approved, NEMA 12 Control Panel

State-of-the-Art Logic Control

User Friendly Microprocessor with Micro-Switch Keypad

Revo-Logic™Exact Wrap Counting Technology

Electronic Film Tension Control Adjustment on the Panel

Separate Top I Bottom Wrap Count Selectors with LED Count Display

Variable Speed Film Carriage Up/Down Control

Film Carriage Raise/Lower Switch (Manual)

Photocell for Automatic Load Height Detection

Turntable Jog Pushbutton

Film Delivery 20” Insta-Thread LT Powered Pre-Stretch Film Delivery System

260% Pre-Stretch Ratio

Easy & Safe to Operate Self-Threading Carriage Design

Variable Speed Film Output (Non-Wearing Sensor)

Heavy Duty Chain & Sprocket Ratio Control

Adjustable Film Roping Bar on Chassis for Stronger Interlocking of Load and Pallet

Film Carriage Elevator Drive Heavy Duty ANSI Chain Carriage Lift

Variable Speed Drive Motor

Multi-Point UHMW Precision Carriage Guidance System

Structural Features 100% Structural Steel Construction Throughout

Easy Access to All Components

Open Mechanical Design for Ease of Maintenance

Forklift Portable Base Design

Structural Steel Tube Mast Design

Hinged Mast for Ease of Shipping, Portability

Estimated Shipping Weight 1,500 Ibs.

Visit our Distributor Support Website at www.support@orionpackaging.com