6

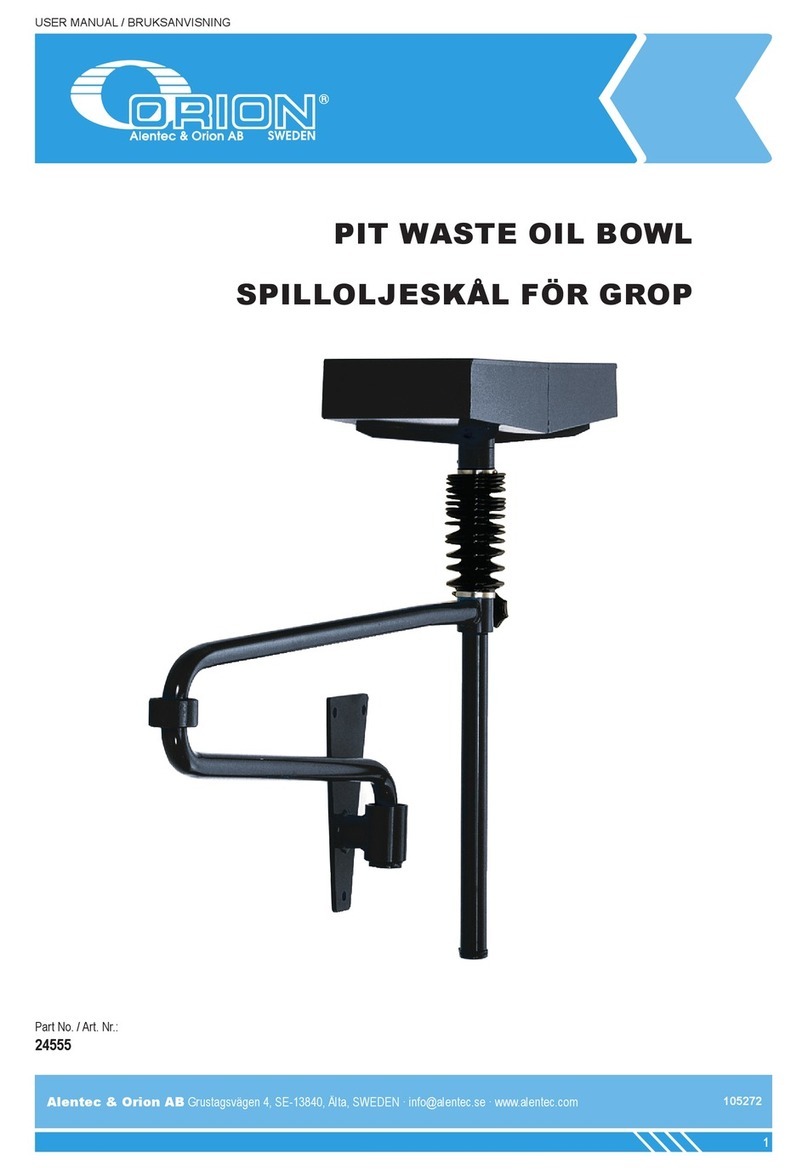

Needle

valve

Drain

plug

How to use this product

CAUTION

●If drainage amount from compressed air is a little, the following phenomena may be induced.

1. Unusual wear of Disc

2. Shortening of Interval of drainage

3. Acceleration of wear of Disc

4. Continuous blow-off from this drain trap

In cases like the above, do not keep using this drain trap. Or continuous blow-off will happen

extremely earlier.

To dissolve it, replace this drain trap with an Electrical Auto Drain Trap or with a Float type

Auto Drain Trap. Or close Ball Valve, equipped between Air Dryer and this drain trap, during

there is no compressed air flow.

●If the product is installed at the place where too much oil mist exist, the following phenomena

may be induced.

1.Drainage will deerease.

2.Intervals of drainage become longer.

In case of installation where too much oil mist exist, adjust the needle regarding to

“important” below.

1. Adjusting the quantity of drainage water

With this drain trap, intervals of operation vary according to conditions (load, pressure, etc).

To prevent the bowl from being filled with water, adjust the needle valve.

●Adjusting intervals of drainage

The quantity of drainage water varies according to use conditions

(operating pressure, etc.); adjust the intervals of drainage with

the Auto Drain Trap's needle valve. Adjustments should be made

so that the level of water in the bowl is visible from outside (i.e.,

the bowl is not filled with water). Too short intervals of drainage will

consume much extra air.

Conversely, too long intervals will accumulate much drainage. As

the needle valve is turned in the plus (+) (open) or minus (−)

(close) direction, shorter or longer intervals are obtained,

respectively.

●Regarding the needle valve

Do NOT forcibly turn the needle valve in the minus (−) direction; this may Cause damage to

its internal parts and drainage could be continuously discharged as a result.

●Sounds generated during drainage

If you prefer a quieter system for environmental reasons, it is recommended to install an

optionally available muffler (for AD-5); or use a float type Auto Drain Trap (FD-10-A) in

place of this product. For details, see the optional parts, consumables, and replacement parts

on page 12 and contact the dealer that you purchased the product from.

●Regarding intervals of drainage

Intervals of operation were set to 25 to 37 per 30 seconds (0.59 MPa) prior to shipment

(only compressed air can be used for operation). The continuous blow-off time setting is 3

seconds or less. Intervals may vary in the course of operation and continuous blow-off could

occur; however, this is not a failure.