9

Installing the chairlift on the rail

1. Check if lift is functioning OK.

2. Remove the end plate and the buffer from the top of the rail

See figure.

3. Place the chair on the rail. Check during putting the lift on the

rail that the overspeed governor does not grip the rail and in

case of a lift with sensor, that you do not damage the sensor.

Before step 4, make sure that the drive unit is on the rail

correctly, the counter pressure roll is around the bottom tube

of the rail and that the toothed wheel against the toothed rack.

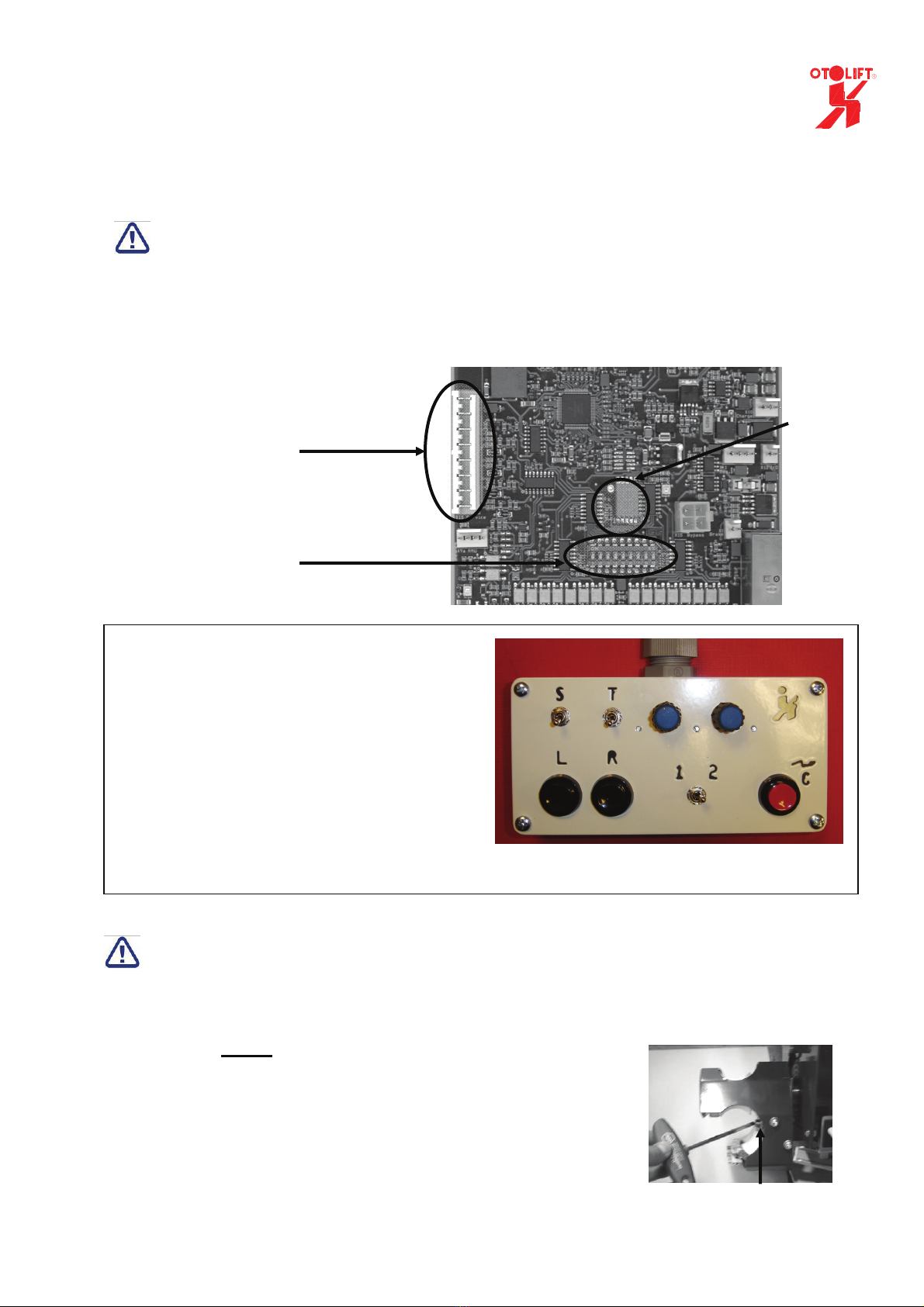

4. Connect the service box to the main PCB of the chair.

Make sure that all the switches on the service box are switched off (pointing downwards)

5. Switch on the manual operation, by switching “Service” on the service box upwards.

6. Set the speed of the motor to a low level by adjusting of the potentiometer on the service box.

(counter clock-wise= low speed)

7. Drive the chair slowly on to the tooth rack by operating the switches “left” or “right” on the

service box.

8. Assemble the endplate and the buffer at the top of the rail. Move the lift a little downwards to

remove the transport standard.

9. Check if the safety switches on the gearwheel covers are functioning properly by operating the

switches during movement.

Testrun

1. Drive the chair completely to the bottom of the stairs to check the proper running, by using the

service box.

(in case of a sensor keep monitoring the distance between sensor and lower tube)

Do not forget to remove the clamp and the piece of toothrack, which was used for coupling the

railparts and watch out for clearances between lift and other objects.

2. The chair has to stop, when the gearwheel cover (safety-cap endswitch) runs into the buffer.

During the test-run you monitor the spacing between chairlift and the staircase or other object

which can obstruct the way of stairlift.

3. Also check the spacing to objects or staircase, with the footplate in fold out position and

armrest in upwards position.

Check correct function

of endswitch

Buffer and

endplate mounted

Placing the chair

on the rail

model 2002