OUMAN EH-203

6

SETTINGS

Settings: Factory

settings:

Explanation: Attention!Range:

Room sensor (TMR) must be con-

nected (H1:meas.3, H2: meas. 6, or

net). An appropriate room compen-

sation ratio for oor heating is usu-

ally between 1.5 - 2.0°C.

Transmitter must be connected,

the same sensor for regul. circuits

H1 and H2 (meas. 6).

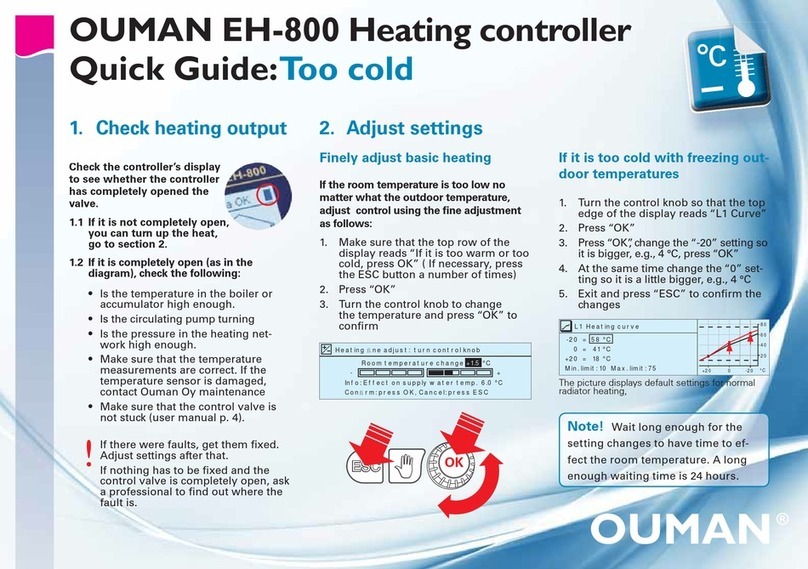

Changing the domestic hot water temperature:

Changing the heating regulating circuit setting:

Press the button to move the cursor to the setting that you want to

change. Press OK. Press the -or + button to change the setting.

Press OK. Exit with ESC.

H1 Settings

Room temp. 21.5

Temp drop(w) 0

Min.limit 15

Max.limit 70

Parall.shift 0

RoomCompens. 4

E-compens.r.

0

Pre-increase 0

Autumn dry 2

Burner ON 70

El.Heater ON 50

Valve close 19

R1 Temp.lim. 55

H1 Select

Heating curve

Settings

Measurements

HW Settings °C

DomHot wat. 55.0

HW

H2 Automatic

H1 Automatic

Outdoor -15°C

SupplyTemp52°C

Selection

Room temp.

Temp drop (w)

(supply water)

Min. limit

Max. limit

Parall.shift

Room compens.

E-compens.r.

Room temperature setting, which user has set.

During temp. drop period regulator use the calculated room

temp. setting.

The supply water temperature drop, determined by the clock

program or the external home/away switch. (Room com-

pensation takes a desired drop in room temperature into ac-

count).

Minimum allowed supply water temperature. Set the minimum

limit for oor heating circuit tiled oors between 20...25°C, to

ensure a comfortable temperature and removal of moisture in

the summer.

Maximum allowed supply water temperature.

The maximum limit prevents the temperature in the heating

circuit from rising too high, preventing damage to pipes and

surface materials. If, e.g., the characteristic heating curve set-

ting is incorrect, the maximum limit prevents excessively hot

water from entering the network. Set the upper limit for oor

heating between 35...40°C.

A parallel shift occurs when a change in supply water tem-

perature occurs at each adjustment point.

Room compensation ratio: If the room temperature is different

than what it is set at, the room compensation corrects the

supply water temperature. (Eg.) If the room compensation is

4 and the room temperature has risen 1,5 °C above the set-

ting, the regulator drops the supply water temperature 6 °C

(4x1,5 °C =6 °C)

E-compensation ratio: Compensation relation shows how

much the E-compensation can, at the most, make the heating

water temperature rise or sink. E-compensation is used for

example where wind and sun measurement is used.

21,5 °C

0 °C

15 °C

70 °C

0 °C

4.0 °C

0 °C

5...45 °C

0...35 °C

5...70 °C

15...125 °C

-15...+15 °C

0.0...7.0 °C

-15...15 °C

In Ouman EH-203 the regulator is controlled by many different

settings. Settings are selected according to sensor connections

and relay control modes (e.g., is a relay controlling the oil

burner or pump or is the relay temperature controlled see p. 26-27).

By browsing you can see which settings you have in use.

Browsing and setting changes occur in the following way:

Use the button to move to domestic hot water

regulating circuit (HW). Press OK.

Press the - or + button to change the setting. Press

OK. Exit with ESC.

Press the button to move cursor to ”Settings”. Press OK.

INFORMATION ABOUT SETTINGS:

Room compens.

Temp drop(w)

80

65

50

35

20

-20 °C020

Maximum limit

80

65

50

35

20

-20 °C020

Parallel shifts

80

65

50

35

20

-20 °C020

Minimum limit

OPERATING INSTRUCTION:

Press ESC until the display no longer changes.

You are then in the ”Selection” display shown in the adjoining picture.

Use the button to move from one regulating circuit to the next (H1, H2, HW).

Calculated room temp. setting =