3

Table of contents

34

34

34

34

34

34

34

35

37

38

40

42

42

43

43

44

46

51

52

53

54

56

59

60

Taking the H2 control circuit into use ....................................

H2 Process settings ...............................................................

Selection of heating mode ............................................

Actuator selection .............................................................

Actuator driving time..........................................................

Selection of type of heating curve .................................

Labeling heating circuits ..................................................

Relay control .............................................................................

Valve ushing ...........................................................................

Text message settings ...........................................................

EH-800 network settings ......................................................

Display settings .......................................................................

Initiation of locking code ........................................................

Changing the locking code ....................................................

Type information ......................................................................

Communication via a mobile phone ............................

Special settings ...............................................................

Optional equipment .......................................................

Installation guide ............................................................

EH-800 connections..........................................................

EH-800 initial setup..........................................................

What to do if there is a fault ..........................................

Index ..................................................................................

Technical information .....................................................

4

5

6

6

7

8

10

11

13

14

14

15

18

18

19

20

20

21

22

22

23

26

26

28

29

30

31

32

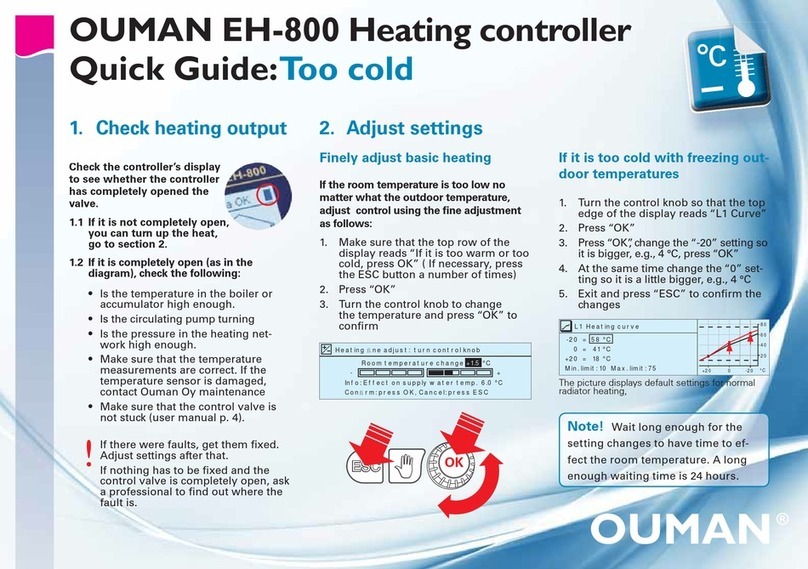

Fine adjustment ................................................................

Heating curve settings .....................................................

Säätöpiirikohtainen perusvalikko ..................................

Measurements ..........................................................................

Graphic presentation of meas. history information..............

Supply water info ......................................................................

Room temperature info ............................................................

Settings .......................................................................................

Control modes ...........................................................................

Other controls ...................................................................

Home/Away control...................................................................

Relay control ...............................................................................

Clock functions ..................................................................

Temperature drop Weekly/24-hour program .......................

Exception calendar ....................................................................

Setting the time and date ........................................................

Alarm message .................................................................

Alarms .................................................................................

Device settings ..................................................................

Language/Kieli/Språk ................................................................

Settings for measurement channels ....................................

H1 Process settings....................................................................

Selection of heating mode ...............................................

Direction of valve ................................................................

Selection of type of heating curve ...................................

Labeling heating circuits ....................................................

Cascade control ...................................................................

Hybrid heating........................................................................

Temp. of water entering the heating circuit

= valve completely open

= valve completely closed

= valve opening

= valve closing