8

TEST PROCEDURES

LIGHT SOURCE MODEL NUMBERS:

DO2xx

DO2-85xx

DO2-13xx

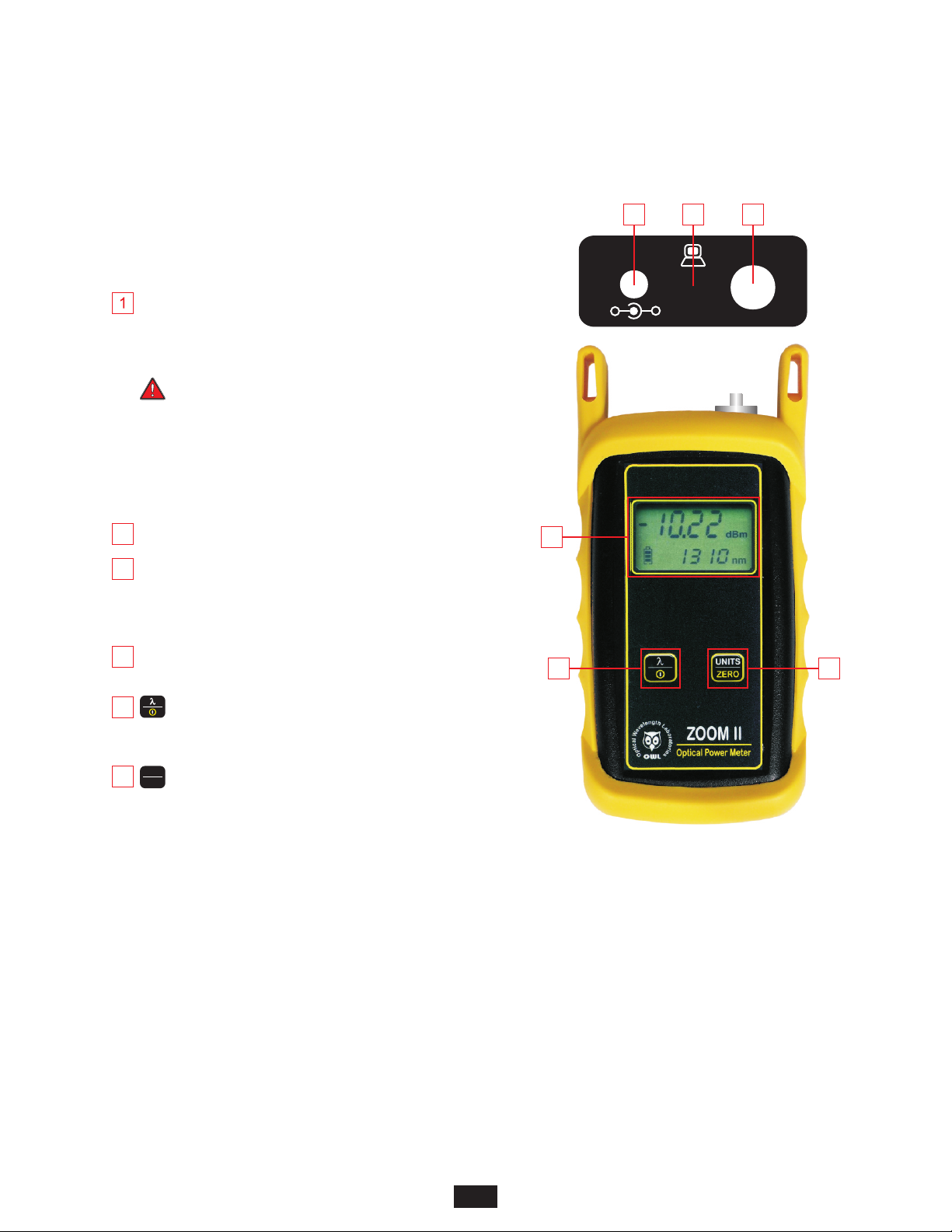

Checking ZOOM 2 Series Optical Power Meters

For Proper Operation

USING OWL DUAL OWL SERIES MULTIMODE SOURCES

Checking ZOOM 2 Series Optical Power

Meters for Proper Operation

USING A DUAL OWL MULTIMODE LIGHT SOURCE

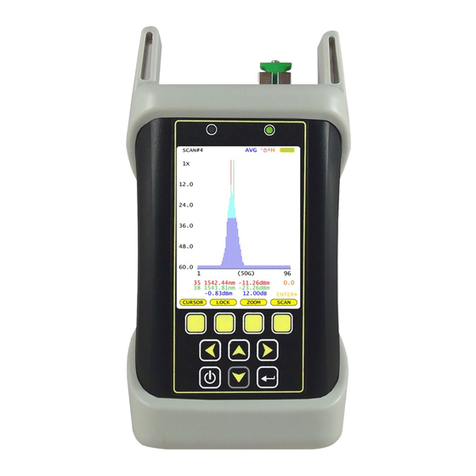

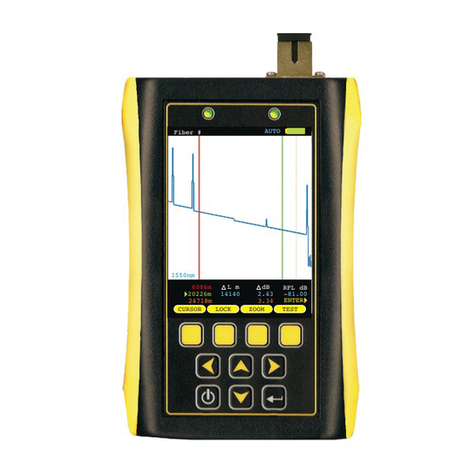

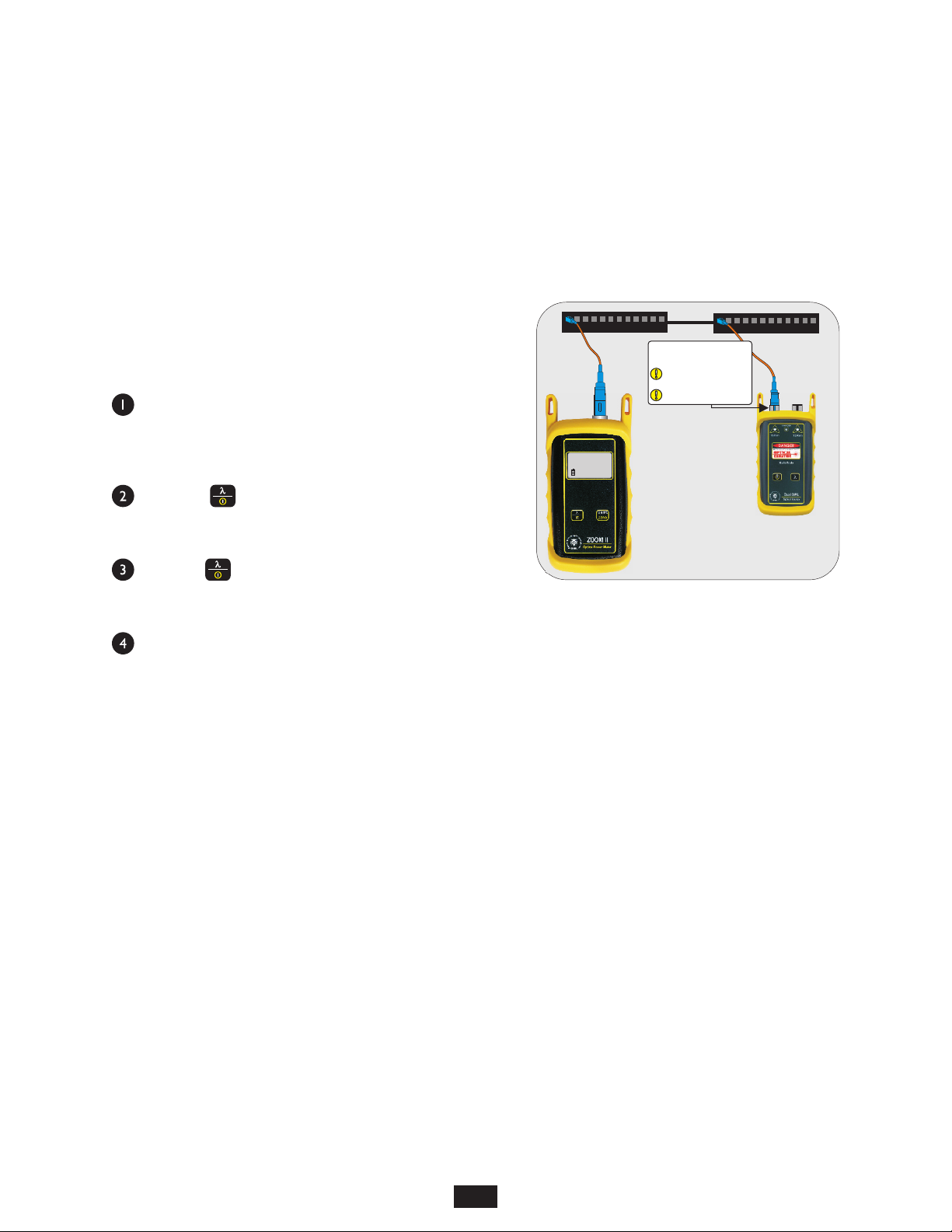

STEP 1 - Connect ZOOM 2 and Dual OWL

Connect the ZOOM 2 and Dual OWL together with an orange

multimode patch cable as shown below.

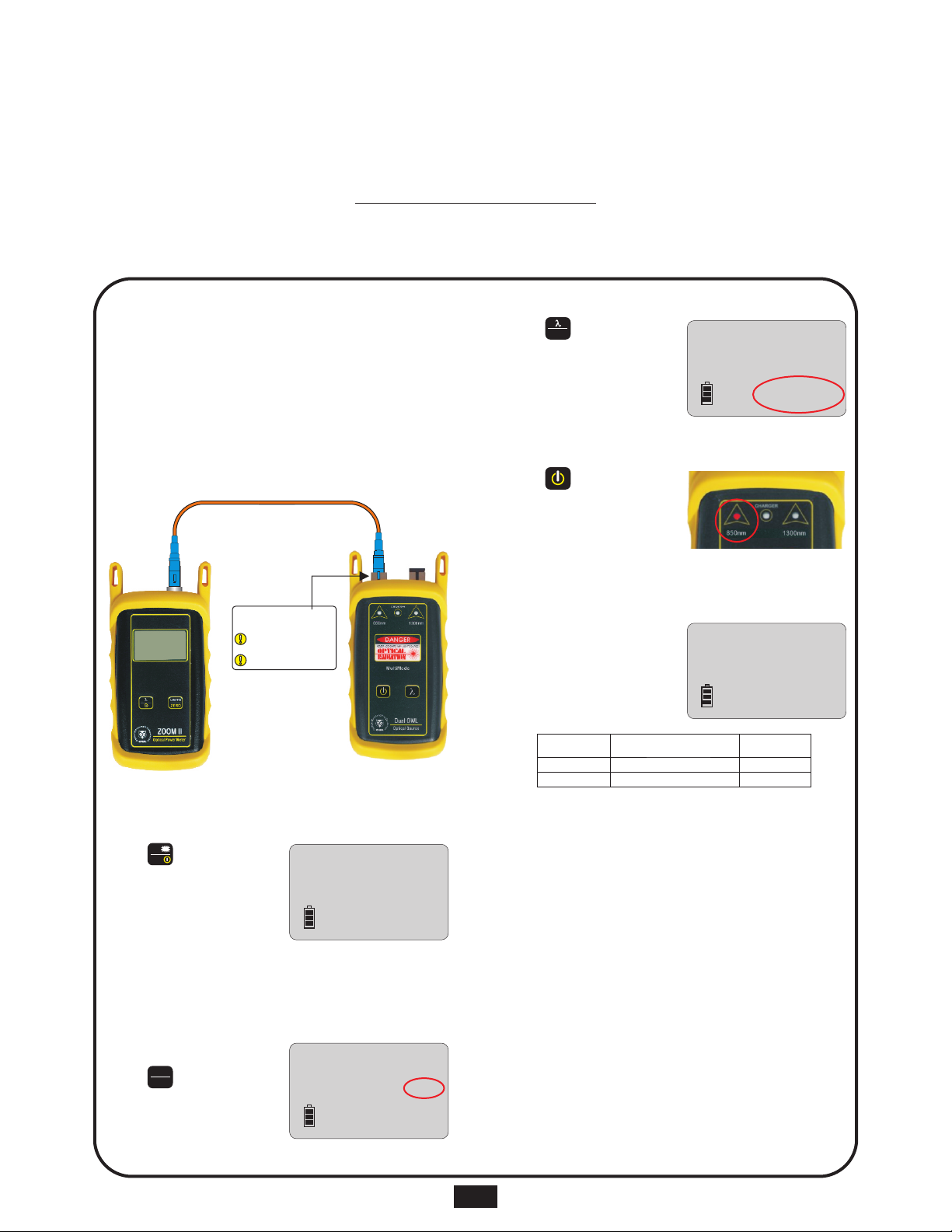

STEP 2 - Power ON the ZOOM 2

Press to power on the

ZOOM 2.

After a few seconds, the ZOOM

2 display should read ‘LO’, and

will appear similar to the

diagram shown at right.

NOTE: the wavelength and measurement units may be different

from the display at right.

STEP 3 - Set the ZOOM 2

to ‘dBm’

Press on the ZOOM 2

until the measurement units

read ‘dBm’ as shown at right.

You may need to press the

button several times.

NOTE: it is recommended to thoroughly clean and inspect all

patch cord connectors before making any connection.

OF F

ON

U NIT S

Z E R O

dBm

.8. . .8lo

-

i850

nm

dBm

.8. . .8lo

-

i850

nm

DUAL OWL

connected to

850nm port

STEP 4 - Set ZOOM 2 to 850nm

Press on the ZOOM 2

until the wavelength display

shows ‘850nm’ as shown at

right. You may need to press

the button several times.

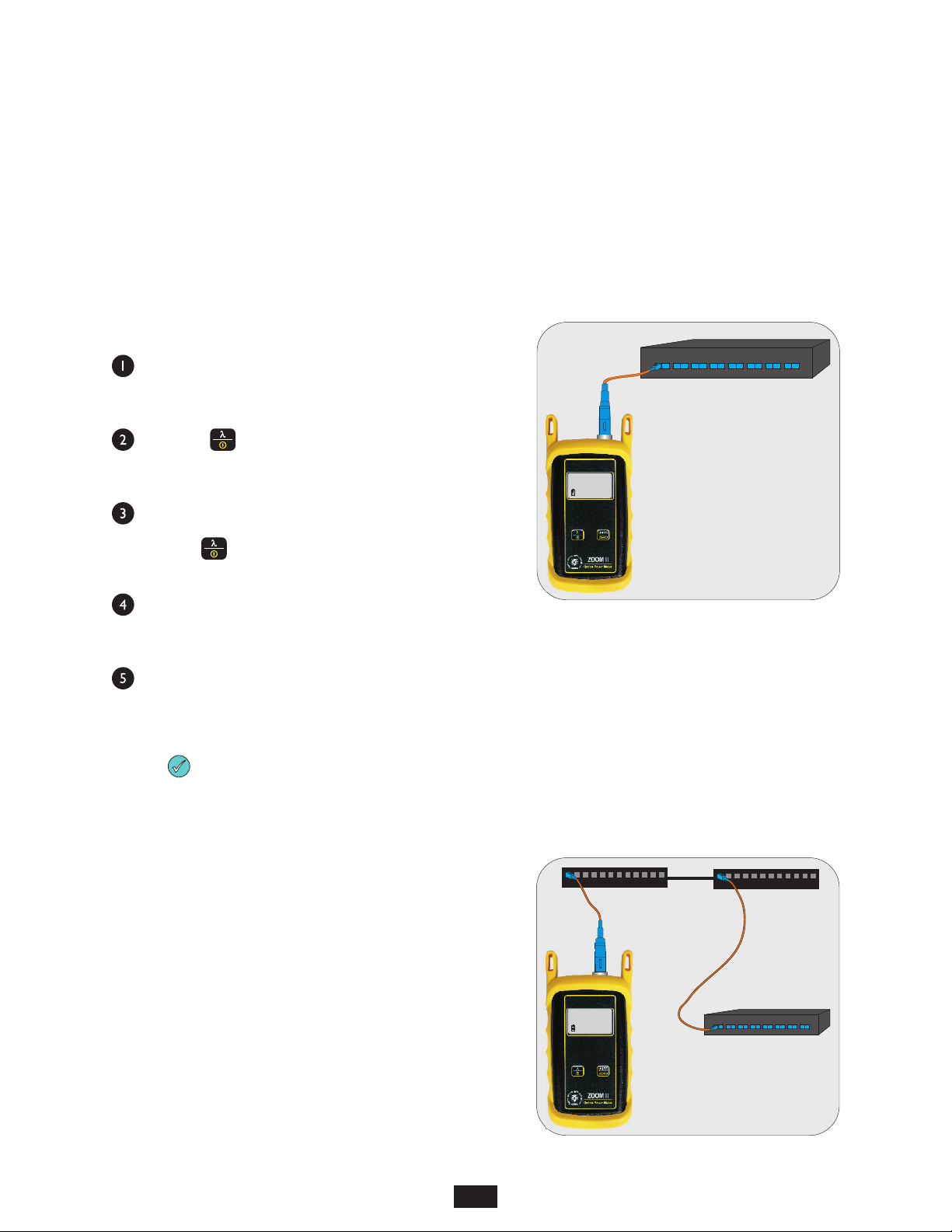

STEP 5 - Power ON the Dual OWL

Press to power on the

Dual OWL.

The 850nm indicator LED

should now be lit as shown at

right.

STEP 6 - Check optical power

The power reading that appears

on the ZOOM 2 display will

depend upon cable type.

Consult the table below for a list

of acceptable power readings.

STEP 7 - Replace the patch cable

The easiest way to troubleshoot low power levels is to try another

patch cable. Over time, patch cables can wear out or become

damaged the more they are used for optical loss testing.

Replacing the patch cable usually fixes the problem.

STEP 8 - Clean patch cables and optical ports

If the problem still exists after patch cable replacement, there

may be some debris, such as dust, dirt, or finger oil, that has

collected on the connector endface or in the equipment optical

ports.

Thoroughly clean and inspect the optical ports of the ZOOM 2

and the Dual OWL, as well as the fiber connector endfaces,

according to the brochures that have been included with this kit.

Several cleaning cycles may be required.

If the power level is still too low, even after a thorough cleaning

and inspection and patch cable replacement, contact OWL

technical support at 262-473-0643 for more information.

NOTE: the following steps are only required if the optical power

reading on the ZOOM 2 is too low.

AU T O

dBm

.8. . .8lo

-

850

nm

dBm

.20.00

-

850

nm

Core Size

62.5/125 µM

50/125 µM

Replace at

-21.00 dBm

-24.00 dBm

Acceptable Power Level

-19.0 to -21.0 dBm

-22.0 to -24.0 dBm

SC connectors shown here;

connector style may vary

LIGHT SOURCE

CONNECTOR PORTS

Do NOT insert APC connector

into either light source port