●This product has been developed / produced for industrial use only.

●This product is suitable for indoor use only.

●Avoid using the product in an explosive atmosphere because this prod-

uct does not have an explosive-proof protective construction.

●Make sure that the power supply is off while wiring.

●Take care that wrong wiring will damage the product.

●Verify that the supply voltage variation is within the rating. Take care that

if a voltage exceeding the rated range or an AC power supply is directly

applied, the sensor may get damaged or burnt.

●If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

●In case noise generating equipment (switching regulator, inverter mo-

tor, etc.) is used in the vicinity of this product, connect the frame ground

(F.G.) terminal of the equipment to an actual ground.

●Do not run the wires together with high-voltage lines or power lines or

put them in the same raceway. This can cause malfunction due to in-

duction.

●Do not use during the initial transient time (approx. 0.5 sec.) after the

power supply is switched on.

●Cable extension is possible up to total 10m with 0.3mm2, or more,

cable. However, in order to reduce noise, make the wiring as short as

possible.

●Make sure that stress by forcible bend or pulling is not applied to the

cable joint.

●Since the output does not incorporate a short-circuit protection circuit,

make sure to use this product within the specification and take care

against wrong wiring.

●In case a surge is generated in the used power supply, connect a surge

absorber to the supply and absorb the surge.

●Make sure to use an isolation transformer for the DC power supply. If

an auto-transformer (single winding transformer) is used, this product or

the power supply may get damaged.

●Avoid dust, dirt, and steam.

●Take care that the product does not come in contact with oil, grease or

organic solvents, such as, thinner, etc., strong acid or alkaline.

●This sensor is suitable for indoor use only.

CAUTIONS

8

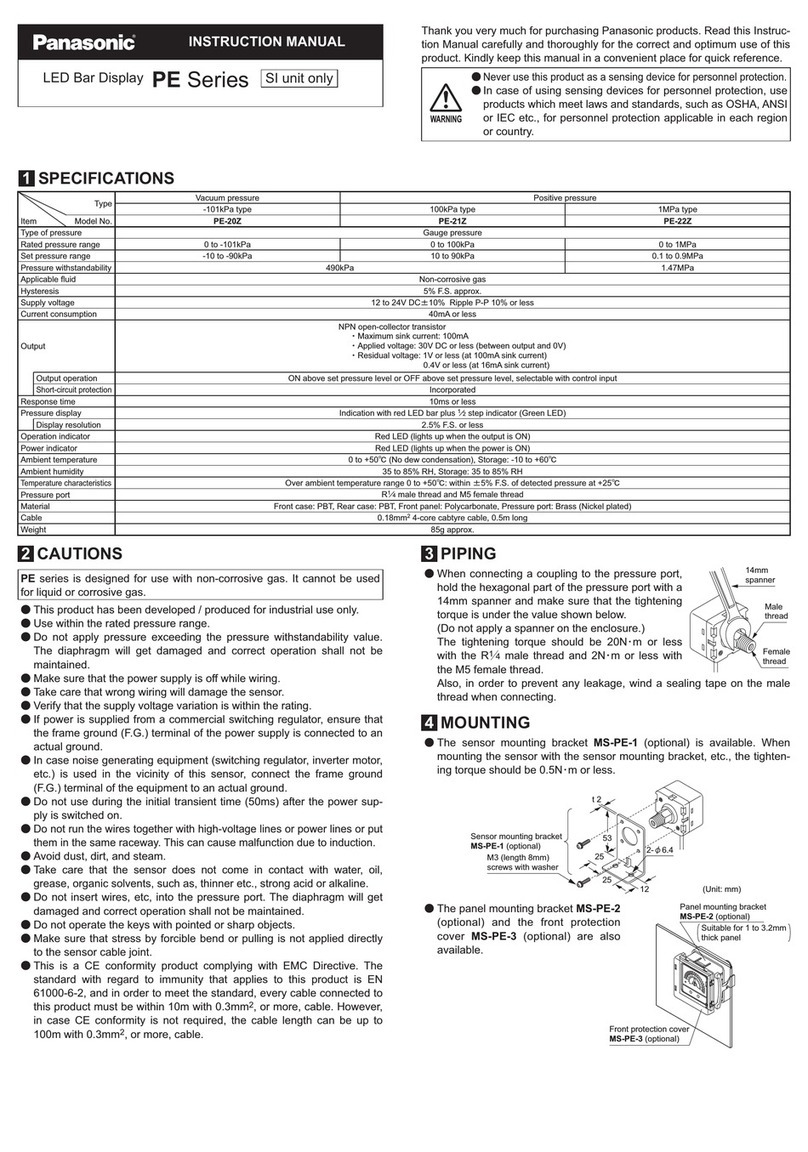

SPECIFICATIONS

7

Designation Simple wire-saving unit for leak detection sensor

(NPN output type)

Model No. EX-FC1

Connectable sensor NPN output type leak detection sensor (EX-F71, EX-F72,

EX-F61, EX-F62) (Note 1) (Note 2)

Applicable connector SL-CP1

Supply voltage 12 to 24V DC±10 % Ripple P-P 10% or less

Current consumption

50mA or less (for one unit)

135mA or less (including the sensor input current when all

outputs are ON)

Output

Relay contact 1a

• Switching capacity: 30V 1A DC (resistant load)

• Min. applied load: 10mV 10μA DC

• Electrical lifetime: 100,000 times or more

(rated load, switching frequency 20 times/min.)

• Mechanical lifetime: 50,000,000 times or more

(switching frequency 180 times/min.)

Output operation

The output relay is ON when the input signal from the sensor is ON.

Response time 5ms or less (excluding the response time of the sensor)

Input points 8 points

Ambient temperature -10 to +60ºC (No dew condensation or icing allowed)

Storage: -20 to +70ºC

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Material Enclosure: ABS, Terminal part: PBT

Cable 0.2mm24-core cabtyre cable, 2m long

Weight Approx. 85g

Accessory SL-CP1 (Snap male connector): 8 pcs.

MS-SL-2 (Unit mounting base): 1 pc.

Notes: 1) PNP output type sensor (including leak detection sensor) cannot be connected.

10101 2) Ordinary sensor (NPN output type) or no-voltage contact output sensor can be

connected.

INTENDED PRODUCTS FOR CE MARKING

9

●The models listed under “ SPECIFICATIONS” come with

CE Marking.

As for all other models, please contact our ofce.

●Contact for CE

Panasonic Marketing Europe GmbH Panasonic Testing Center

Winsbergring 15, 22525 Hamburg,Germany

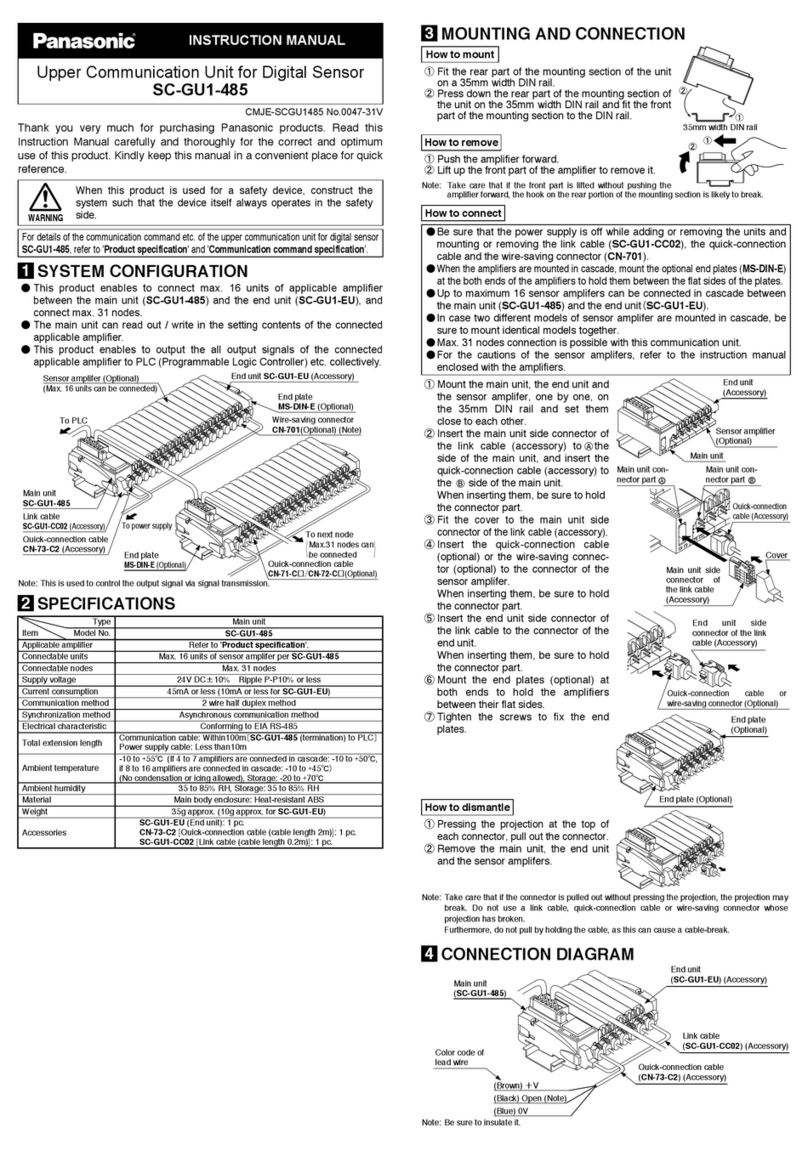

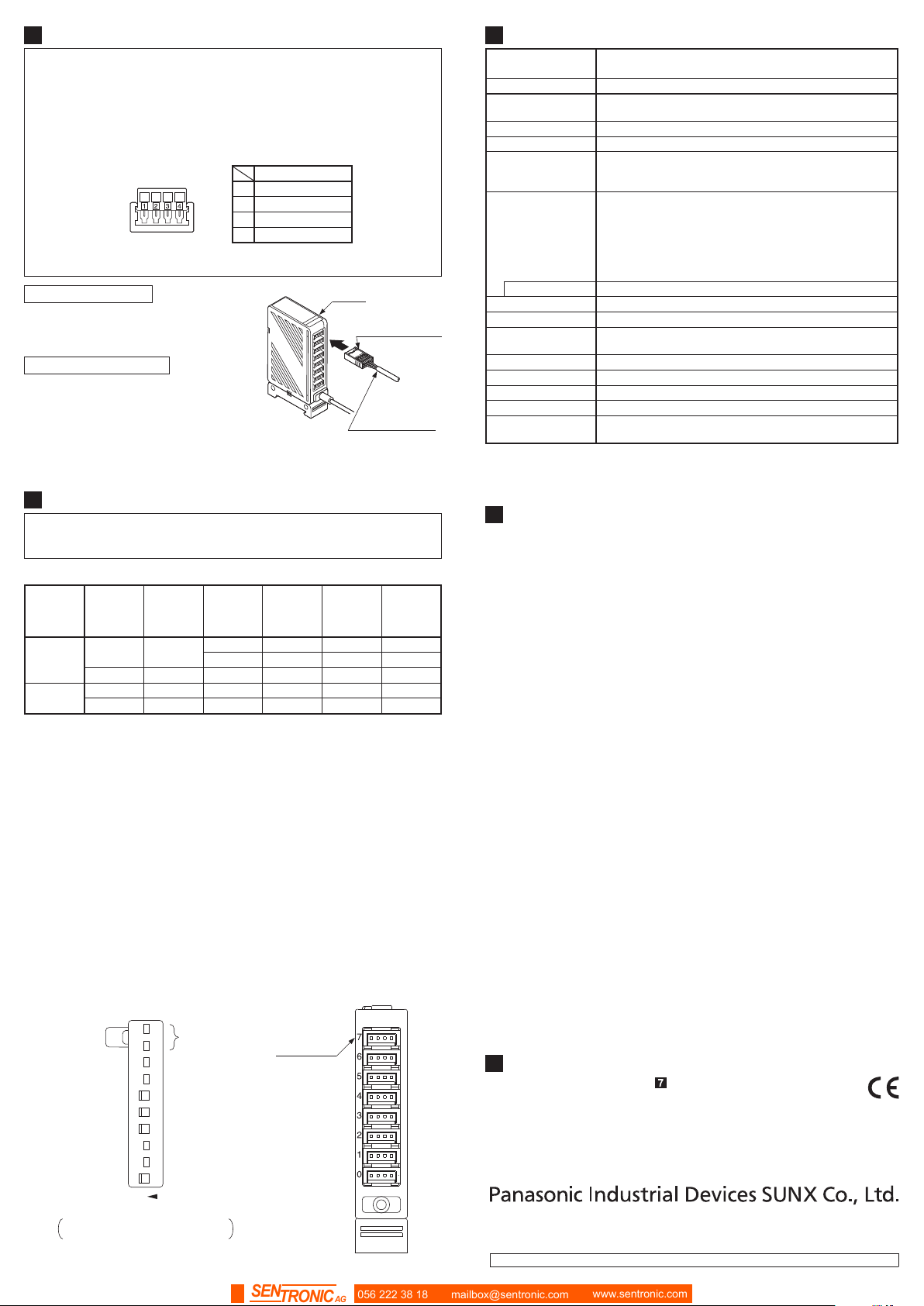

CONNECTION

5

●PNP output type sensor (including leak detection sensor)cannot be

connected.

●Make sure to connect or disconnect the snap male connector (SL-CP1)

in the power supply off condition.

●Take care that wrong wiring will damage the product.

●The terminal No. 4 of the snap male connector (SL-CP1) is not used.

Take care not to connect to the terminal No. 4 by mistake. Further, if

there are unused wires, please insulate them.

123 4

Content

1 +V

2 0V

3 IN

4 No connected

●For details of the hook-up method of the snap male connector (SL-CP1),

refer to the Instruction Manual enclosed with SL-CP1.

Connection method

1. By holding the SL-CP1 with the cable

connected, insert it into the connector

of the EX-FC1 reliably till it stops.

Note: Do not pull out by holding the cable, as this

can result in cable disconnection.

7

6

5

4

3

2

1

0

SL-CP1

Sensor cable

Disconnection method

2. By holding SL-CP1, pull it from the

EX-FC1 horizontally.

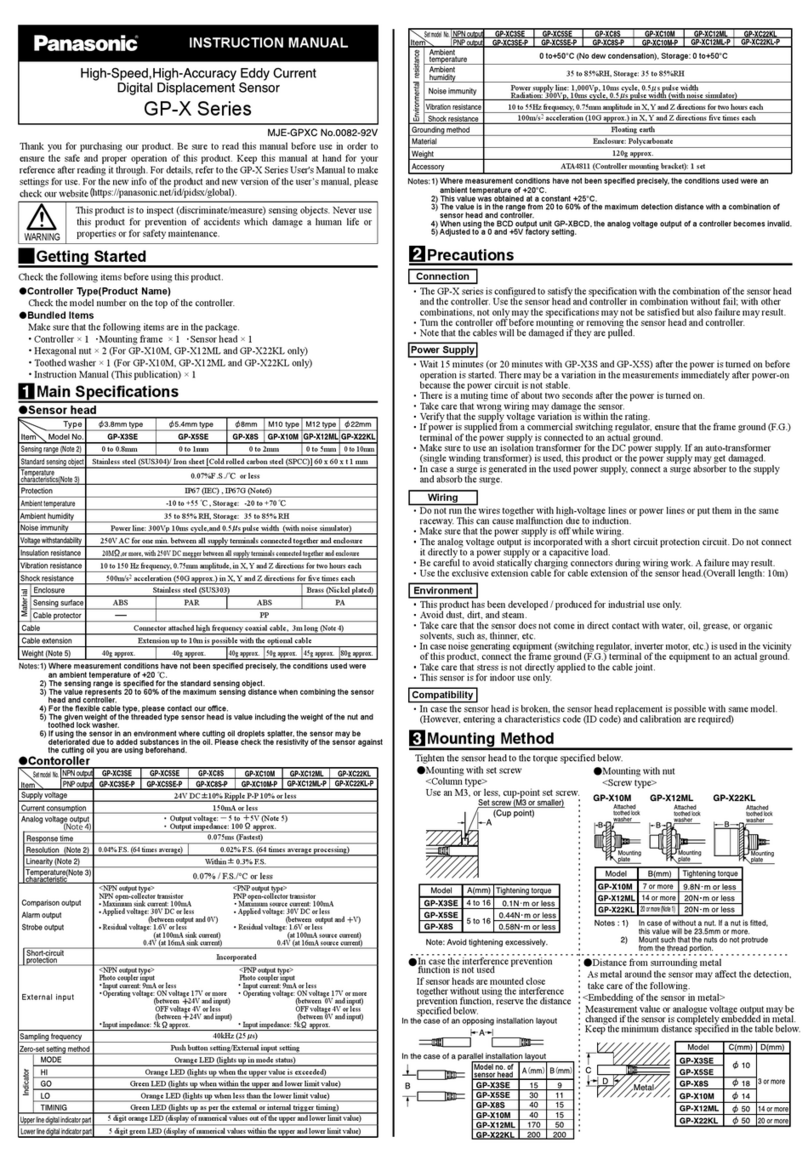

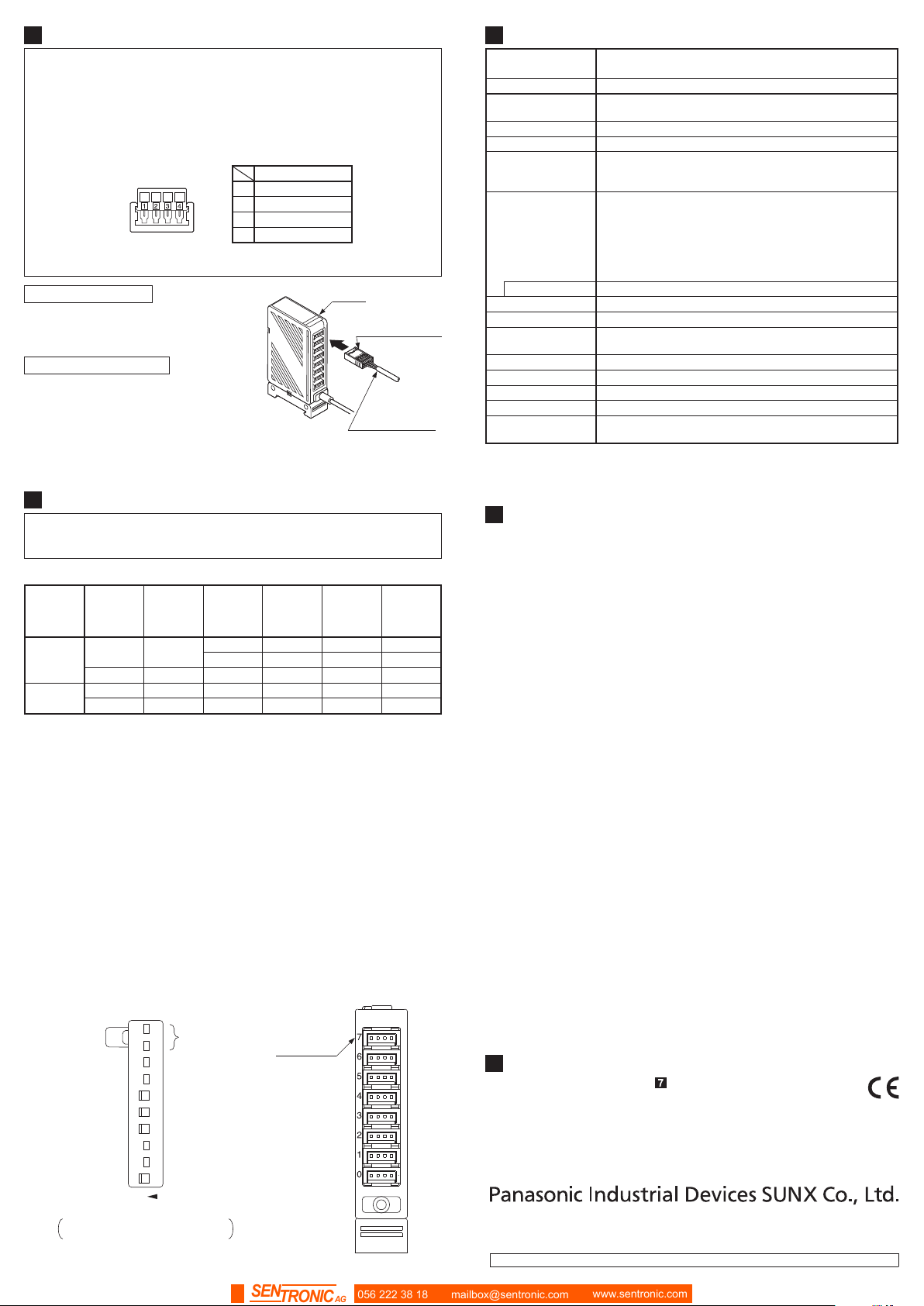

CONNECTION SETTING SWITCH

6

The connection setting should be carried out in the power supply off condi-

tion after removing any electrostatic charge which may be present on your

body.

●Operation matrix for each indicator

Operation

Connection

state of the

leak detec-

tion sensor

State of the

connection

setting

switch

Leak

detected

condition

Normal

indicator

(Green)

Error

indicator

(Red)

Output

indicator

(Orange)

Normal

Connected

ON

Not leaked

Lights up Turns off Lights up

Leaked Turns off Lights up Turns off

Unconnected

OFF

-

Turns off Turns off Lights up

Error

Connected

OFF

Not leaked

Lights up Lights up Turns off

Unconnected

ON

-

Turns off Lights up Turns off

●For the channel that the unit sensor is connected to and the connection

setting switch is set to “ON” side, the error indicator (red) lights up for a

moment when the power is turned on. This is not a malfunction for the

unit because it is caused by characteristic of the sensor.

●Make sure to set the connection setting switch with the connector No. to

which the leak detection sensor is connected, to “ON” side.

●In case both the normal indicator (green) and the error indicator (red)

light up, the connection setting switch with the connector No. to which

the leak detection sensor is connected, is not set to “ON” side. Set the

connection setting switch with the connector No. to which the leak detec-

tion sensor is connected, to “ON” side.

●In case the error indicator (red) lights up, the leak detection sensor de-

tects leak or the connection setting switch is set to “ON” side without

connecting the leak detection sensor. If the connection setting switch is

set to “ON” side without connecting the leak detection sensor, set the

connection setting switch to “OFF” side.

●If the leak detection sensor detects leak or the connection setting switch

is set to “OFF” side in the state that the leak detection sensor is improp-

erly mounted to the mounting bracket, the sensor judges as the output is

ON. Be careful when setting.

NOT

USED

7

6

5

4

3

2

1

0

ON

These are not used.

“ON” side

“ON” side

“ON” side

“ON” side

Connection setting switch setting example

In case the input of 0, 3, 4 and 5 are set

to effective.

Connector No.

https://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Ofce)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

For sales network, please visit our website.

PRINTED IN JAPAN © Panasonic Industrial Devices SUNX Co., Ltd. 2018

056 222 38 18 mailbox@sentronic.com www.sentronic.com

SENTRONIC AG